Six makers, who are a step ahead of most others here in Korea, got together to make quite a splash with those who wanted to learn about 3D printing last week. It was called the “1st Maker Forum with 3D printers: Pleasant Creation” and was hosted by the Leaders in Industry-University Cooperation (LINC) at Dongguk University here in South Korea, and the Seoul Accord Activation Center.

The event was open to anyone who was interested in 3D printing and 3D printers, as long as they pre-registered. From 2pm to 3pm, there was an open exhibition to show some of the finished works, which flew by as people asked questions about the prints and took photos. This exhibition time was a taster of the real show which got started just after 3pm. Around 400 people filled the auditorium and SPOTV’s Yang Han-Na, a popular television anchor, was there as the special MC.The show was originally conceived by three 3D printer enthusiasts: Yi Sang-Ho, CEO of Mand.ro, Son Kyu-Bo, Planning and Marketing Manager of 3Delight Inc., (a major 3D printing total solution provider in Korea) and Hong Jeong-Mo, an Assistant Professor in the Department of Computer Science & Engineering at Dongguk University. I was lucky enough to be invited to their rehearsal, held a week before the actual forum, and was able to ask several questions about the event.

When I asked the purpose of the forum Mr. Son, one of the organizers and presenters said, “All six speakers in this forum met to ‘play’ and create. Depending on how we look at an object, we create it in different ways. And those different ideas and techniques are the point. When many people get together to make something together, more interesting ideas and results will be created.” I understood exactly what he meant when he said ‘play’. The old expression, ‘the more, the merrier’ fits perfectly to what they were trying to do.

Those six people all are from somewhat related, but different fields. There was a CEO, an educator, an author, a software developer, a hardware developer, a fashion designer, and an artist. Though they were at least tangentially related in their professional capacities, one thing that they had in common was an eagerness to make useful items using a 3D printer. There was no doubt about it. These guys are MAKERS at heart.

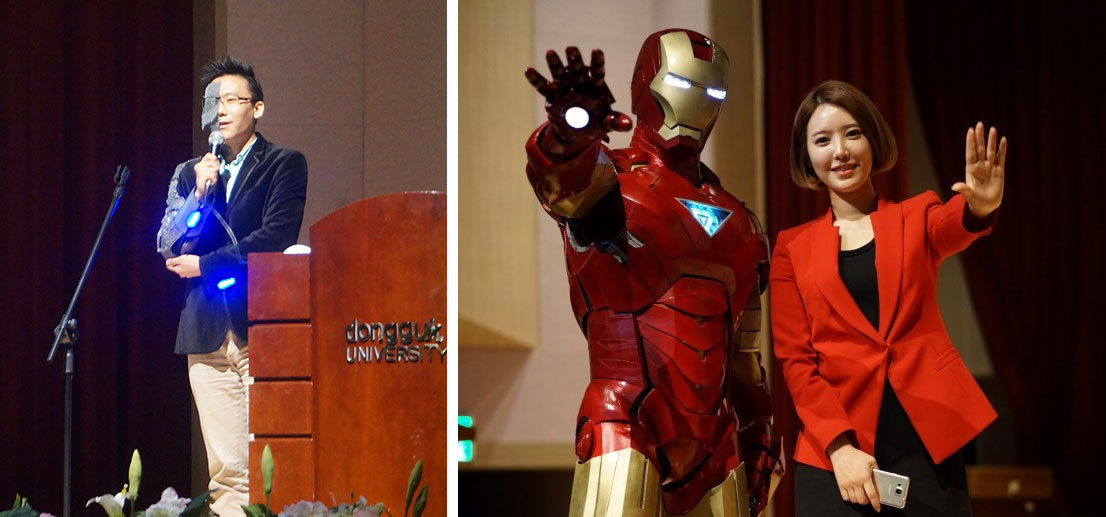

The first speaker up was Kim Dong-Hyeon. The title of his presentation was ‘Do you also want to have an Iron Man suit?’ He showed up on the stage wearing one of two Iron Man suits he had with him. The daunting music and spectacle of the suit heated up the overall mood immediately. He told the crowd in attendance that each of the Iron Man suits took him almost a year to fully build. He shared stories about the process and know-how of how the suits were made using just a desktop 3D printer. The full process can be seen at his blog. His talk was powerful and likely to kindle the passions of all those present who had the heart to make or create something of their own. Afterwards, he said to me, “I would be a maker whether 3D printers came out or not. I would be making what I want to make anyway, but it is true that a 3D printer has made my making process easier. But in the end it all comes down to how persistent and how bad you want to make your item.”

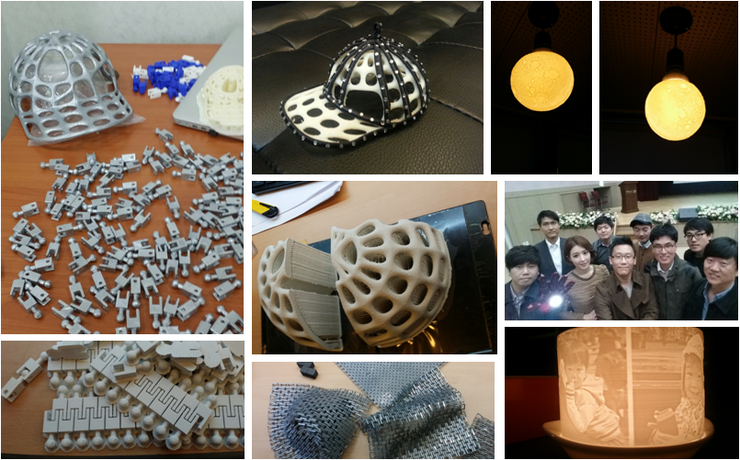

The second speaker was Kim Jang-Ho, who described himself as a ‘Maker to the bone’. He, as a former engineer for LG Electronics, discovered 3D printing by accident — like many others. Later he got really into it and quit his job and applied to OpenCreators, one of the most popular 3D printer manufacturers in Korea today. He now works there as a mechanical engineer. On stage he introduced 13 different plastic models all having distinctive traits, and described how he created them.

One of the features of his products was that he used almost no binder or post-processing. Because of his design expertise, he was able to assemble the parts as they came out of the printer. His ultimate goal is to become a “mechanical artist” who can infuse craftsmanship and the spirit of art into his work. His 3D printed plastic model platforms can be found here.

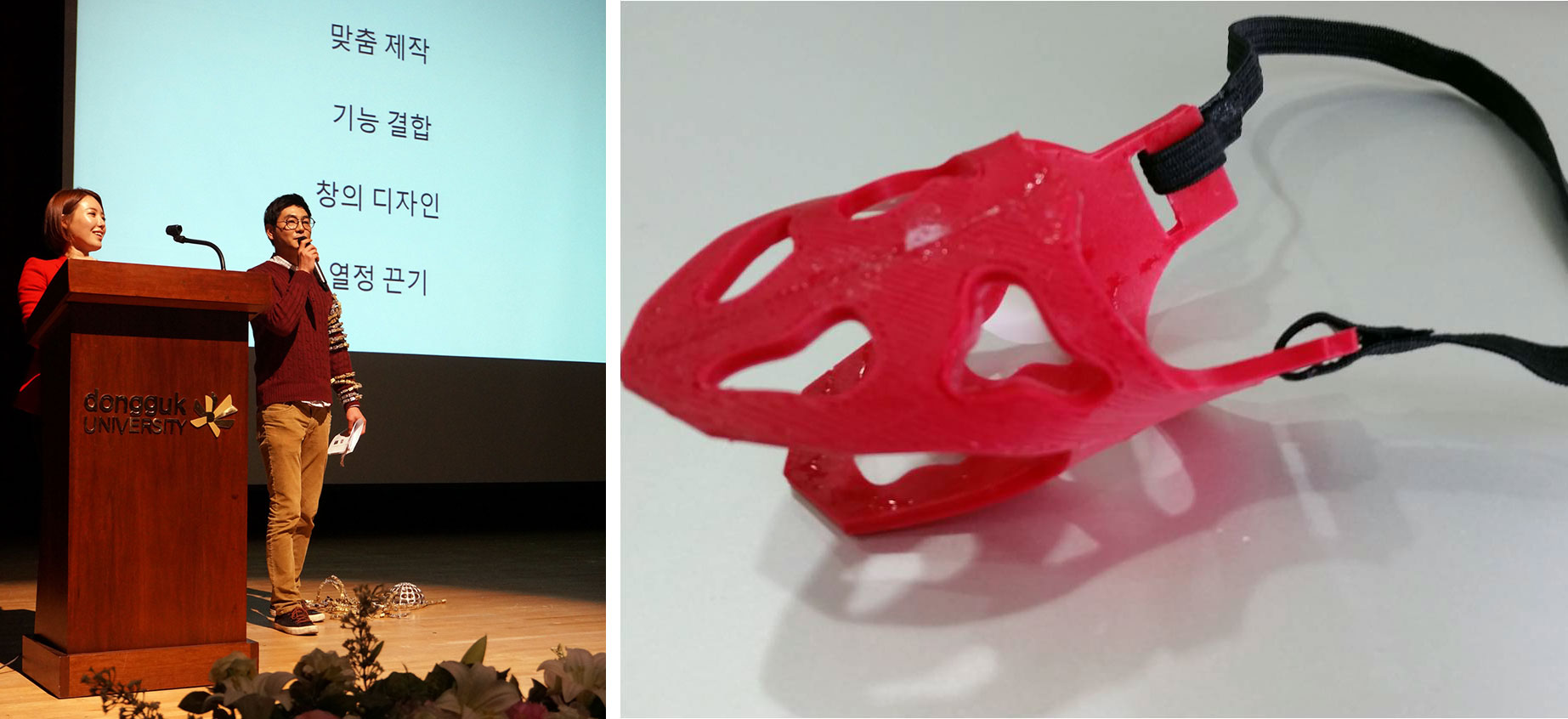

The third presenter was Son Gyu-Bo who gave a presentation called, ‘The Devil Wears 3D Printer (stuff).’ He showed up wearing some prints and introduced himself as a former fashion designer who currently is the Planning and Marketing Manager at 3Delight. He also introduced his mini poodle ‘Hodoo’ and described the time when he was having a hard time trying to calm the puppy down. Since barking dogs can be a real issue in highly populated countries such as Korea, he decided to make what he called a ‘duck mouth’ mask. The mask prevents the dog from barking, but still allows the drinking of water and minimizes the discomfort of traditional muzzles that most people still use. It was made of a flexible plastic and, because the design can be 3D printed easily, it is highly customizable to each puppy or dog’s individual face, making it even more comfortable.

Some of his fashion items were wearable prints with added functions in them. He also talked about some possibilities that 3D printing in the fashion sector can bring. He said, “Large fashion corporations mass produce clothes at low costs, and we get to wear good-quality items at a cheap price. But in a way this kills our creativity and ignores our rights to be different. I want to open an era of customized outfits with 3D printing.”

The fourth speaker was Oh Jin-Uk who now works as a 3D artist, author and educator in the Cultural Contents Academy at Jeonbuk Digital Industry Agency. One of his representative works is the creative animation, ‘Mr. Vending Machine’ that has been invited to several international film festivals. Just prior to the show, he had another exhibition of his 3D prints at the Jenju Hanok Village in Jeollabuk-do Province. Right after he finished there, he hacked his crazy schedule, and came all the way to Seoul to give a lecture here.

At the forum he introduced his ‘Toy Made by My Hands: Toy Maker 3D’ project which he and his students have been working on for about a year. He started the project for people who wanted to create toys for their children by themselves or for people who want to have their own toys. And judging by the number of downloads his designs have had on Thingiverse, he is quite popular. The four designs that he has uploaded so far all have been placed on Thingiverse’s main page and have been downloaded by people from all over the world. His Thingiverse name is Mooncon, and his toy robots, depending on the model, consist of at least 30 to 130 pieces.

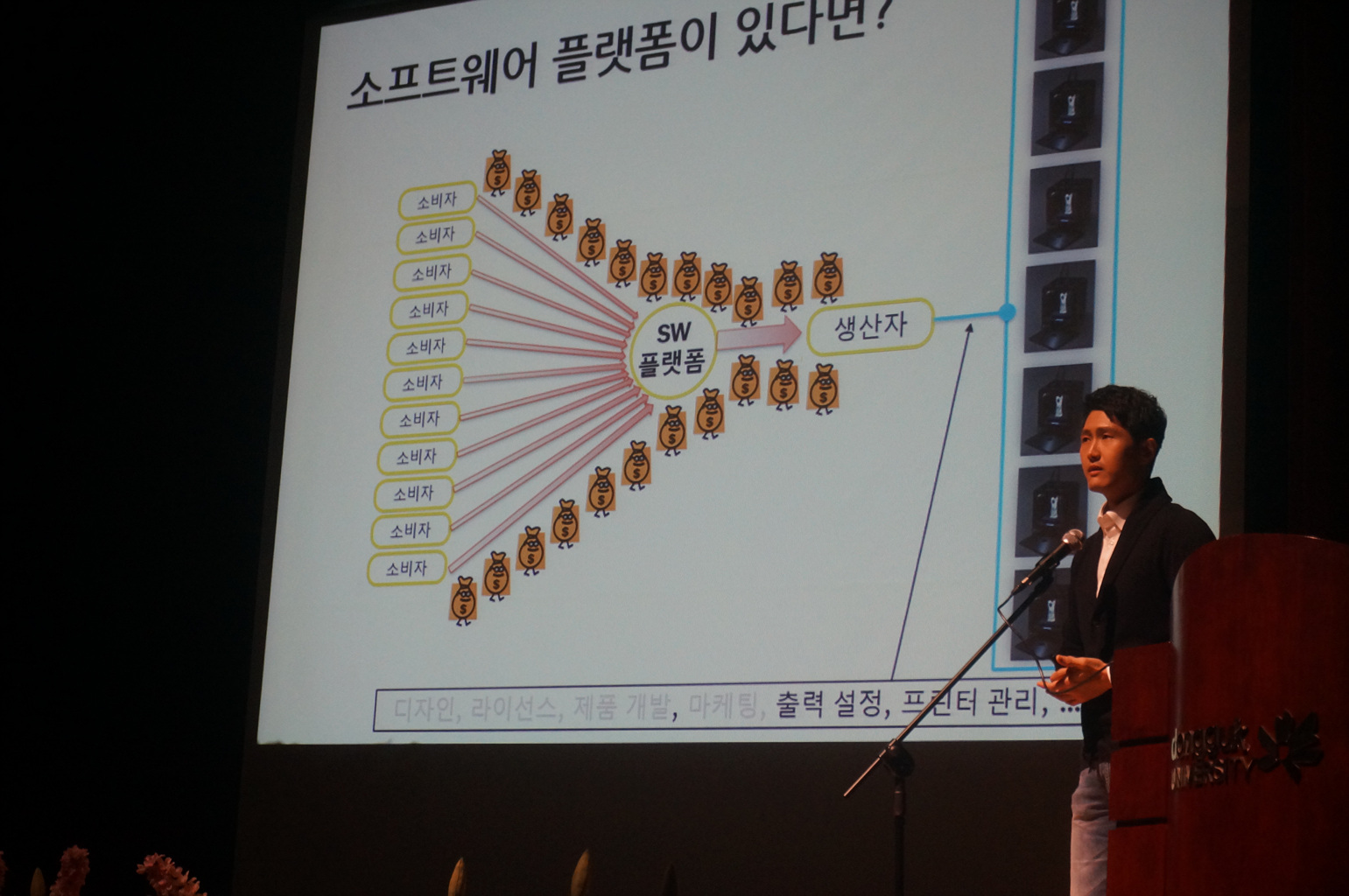

Up next was the fifth speaker; Hong Jeong-Mo, who is an Assistant Professor at Dongguk University. He introduced himself as a programmer and computer graphic expert in the film industry. He told us that he usually deals with fire and water graphic special effects and was involved with some major Korean movies. He started by showing some of his previous computer graphic works. As a programmer who handles graphics and software, 3D printers are, for him, a great tool to actualize what he is working on. He talked about the distribution of profits in the film industry and how profits are unfairly divided. He posited that a solution to such a problem could be resolved through 3D printing collaboration. He said he would like to see — and contribute to — bringing about the change and have those makers compensated fairly for what they create.

He also introduced his lamp project. In essence, it is a cylindrical lamp shade embossed with individual’s favorite photos, 3D printed of course, that become visible when the light is turned on. What’s special about his project is that he shares his web service address on the Thingiverse page so that people can go there and customize the design by putting their own photo images in it and print it out in an easy manner. After only 3 days, he received responses and download requests from 169 cities in 30 different countries, and has received greetings from all over the world. His lamp project can be found here with more details.

Lastly, Yi Sang-Ho, gave a brief presentation under the title, ‘A Manual for You to be a Maker.’ Sang-Ho pointed out some of the strengths that Korea has to encourage and empower makers, as well as some limitations that have to be guarded against. He also announced plans for a Maker forum where makers can present what they have made with their 3D printers regardless of their age, social status or expertise.

Each presentation was supposed to take around half an hour and the forum was supposed to wrap up at 5pm. That was never going to be how it happened! Every time one of the speakers finished their presentation, they were swamped with questions. The MC occasionally requested that attendees refrain from asking questions and to allow the speakers to finish on time. The forum “officially” finished at around 6pm, but…well, due to the crowd’s enthusiasm, the speakers didn’t get out that soon.