Tantalum, like metal 3D printing favourite titanium, has a high weight to strength ratio and excellent biocompatibility.

Highly resistant to heat and chemically inert, the material can be difficult to work with in metal 3D printing processes, but also make it valuable to high stress applications.

Global Advanced Metals (GAM) is a leading producer of tantalum metal powders. Due to the metal’s unique properties, GAM is collaborating with LPW Technology to help process tantalum powders for use in powder bed fusion (PBF).

Tantalum’s qualities

Adding to its long list of beneficial properties, tantalum is highly resistant to corrosion and a viable substitute for platinum. The material is especially useful in sterile/lab environments, and has proved effective for use in medical implants.

GAM is capable of making tantalum powders in nodular, angular, fractal and spherical morphologies. Spherical powders are best for use in metal 3D printing processes. With a fine and regular consistency, spherical powders ensure conformal melting across the build plate, and reduce the risk of imperfections in a finished part.

Processing for powder bed fusion

GAM will leverage LPW’s PBF expertise to ensure accurate processing and development of spherical tantalum powders. The two companies also plan to work together to bring further refractory metals to the additive market.

Andrew O’Donovan, CEO, GAM explains that this partnership, “developed by viewing AM from the perspective of the powder,” represents “one step of our strategy to extend our offering in tantalum and other refractory metals to the additive manufacturing marketplace.”

With LPW, GAM “can now measure and share physicochemical data for both our spherical tantalum and the resulting 3D printed part and bring this solution to our partners, for example practitioners, designers and manufacturers of tantalum based surgical implants and other high reliability and critical devices.”

Encouraging adoption

Confirming a clear demand, LPW has an existing tantalum powder production agreement with Metalysis, also based in the UK.

In relation to working with GAM Ben Ferrar, LPW COO comments, “This initiative demonstrates the benefits of two experts in their fields partnering to expand the materials knowledge-base for AM and accelerate its adoption for production,”

“This work will further develop understanding of the factors affecting tantalum powder spheroidization and how it performs in the AM process, adding assurance to metal AM producers of the material compatibility for AM production.”

For materials partnerships and more, subscribe to the 3D Printing Industry newsletter in the industry, following us on Twitter, and liking us on Facebook.

Join 3D printing jobs now for new opportunities near you.

Vote in the 2018 3D Printing Industry Awards for your materials and technologies of the year. Want to design the trophy? Enter the 2018 3D Printing Industry Awards design competition. sponsored by Protolabs now.

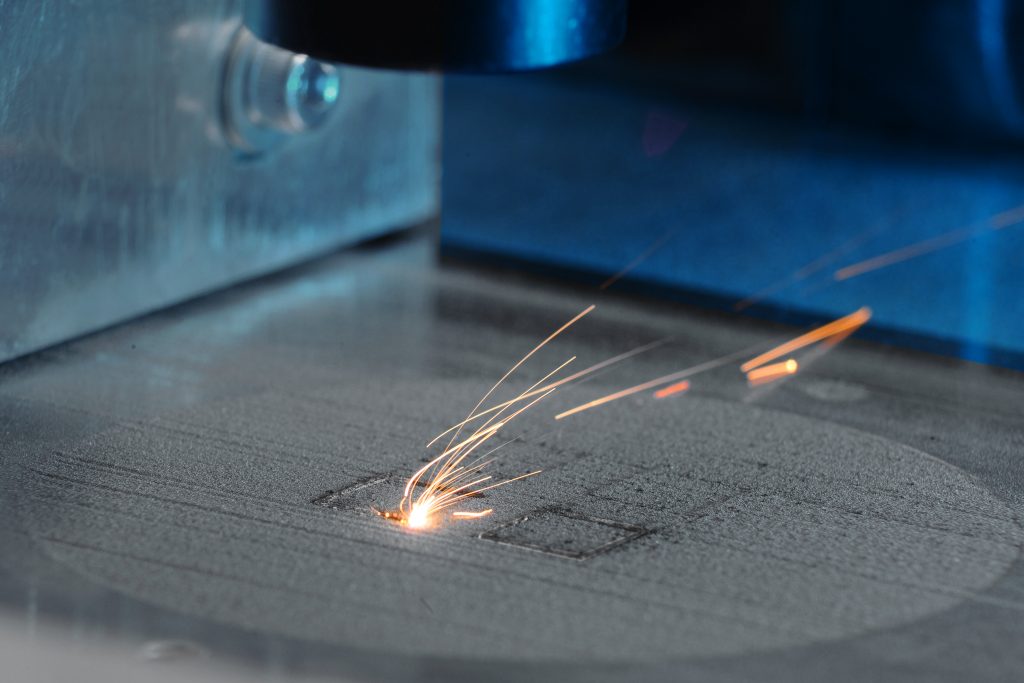

Featured image shows fine particles of tantalum powder. SEM image via GAM