Engineering and technology professional service provider Lloyd’s Register (LR), has partnered with Singapore’s National Additive Manufacturing Innovation Cluster (NAMIC), Autodesk, ST Engineering and AML3D to launch a design competition for a full-scale 3D printed rescue boat.

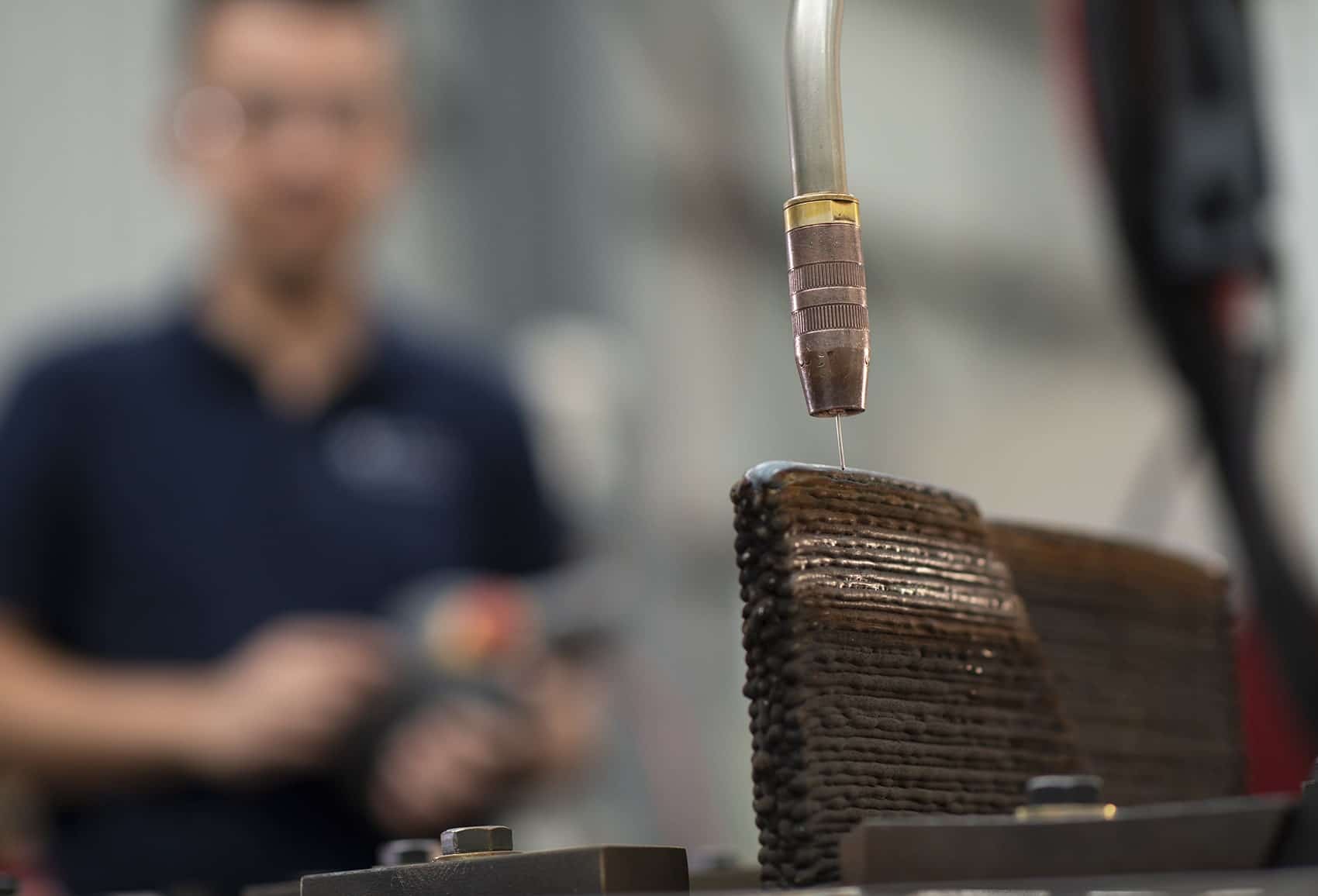

The winner of this global competition will receive SGD $30,000 (£17,500) and their design will be considered for further refinement and manufacturing using Wire Arc Additive Manufacturing (WAAM) or continuous composite fabrication technologies.

“This is a great competition for any shipbuilder, shipyard, manufacturing company or design business interested in submitting their designs with the possibility of winning a significant amount of money to develop their idea using additive manufacturing techniques,” said Hussain Quraishi, Innovation Lead at LR’s Digital Innovation Hub in Singapore.

“We’re particularly looking for entries which embrace the freedom that Additive Manufacturing allows to develop new novel hull designs.”

Additive manufacturing and shipbuilding

Commencing as a marine classification society, LR has become a leading international provider of professional services for engineering and technology. In 2017, with The Welding Institute (TWI), it became the first organization to publish Guidance Notes on the certification of metallic parts made by additive manufacturing.

The new rescue vessel additive manufacturing competition is the first part of a three-phase project to build and qualify a 3D printed rescue boat hull with autonomous sensors. The winning design will be part of a research exercise with Nanyang Technological University (NTU), who will embed the sensors and navigation systems with ST Engineering’s Electronic sector, a global technology, defense, and engineering group.

Australian large-scale metal 3D printing bureau, AML3D, who became the first company to receive additive manufacturing facility qualification from LR, will lead the production of the boat following the incubation and design appraisal phase. This is expected to last around a year.

The first 3D printed rescue boat

According to the partners, the competition will produce the first full-scale 3D printed rescue boat. The rules state that those submitting designs must comply with the Life Saving Appliance (LSA) code, Safety Of Life At Sea (SOLAS) code and Singapore Flag State requirements.

Furthermore, rescue boats must not be less than 3.8m and no more than 8.5m in length and must be able to seat 5 people. It must have power for 4 hours of continuous operation and have a minimum speed of 8 knots. The rescue boat must also be able to operate in Beaufort 6 sea states.

The competition is supported by Singapore’s National Research Foundation (NRF) and the Maritime Port Authority of Singapore (MPA). The submission deadline for designs is March 31st, 2020 and further details on the competition’s rules and guidelines can be found here.

For updates on this competition and more additive manufacturing news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows the WAAM process. Photo via AML3D.