Voting closes soon in the 3D Printing Industry Awards 2023. Have your say now!

Following its partnership with Quantica, Xaar has made its 3-year partnership with Lincsolution public at Formnext 2023. Lincosolution will incorporate Xaar’s Nitrox and Aquinox printheads in its latest metal Binder Jet 3D printers.

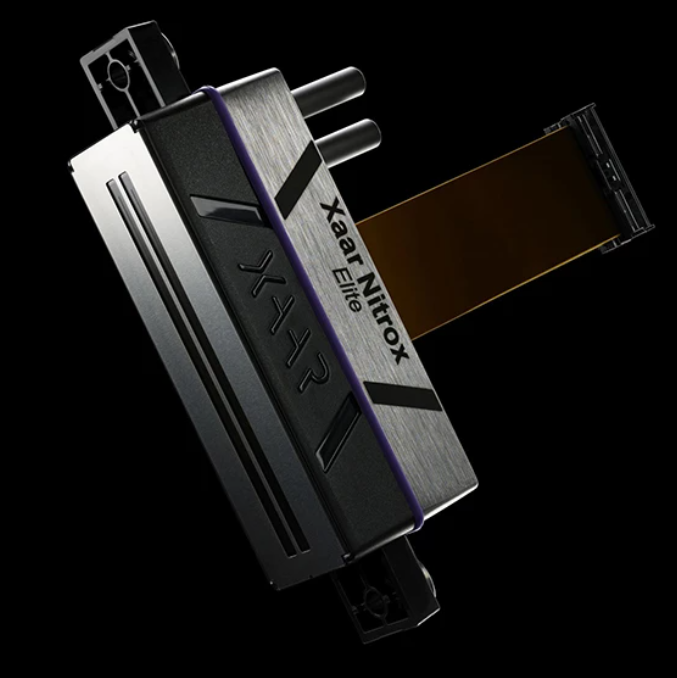

This collaboration aims to introduce advanced machines for automotive, jig, mold, and mass-customization products. Xaar’s Nitrox and Aquinox printheads, known for their reliability, are chosen by Lincsolution and its customers, says the company. The continuous use of printheads in extended production periods highlights the importance of reliability. Xaar’s Hydra fluid management system addresses concerns like printhead clogging and guarantees the quality and precision essential for demanding applications.

Dexter Yoon, R&D Director at Lincsolution, said, “After comparing all the printhead manufacturers, we chose to work with Xaar as their outstanding technological products and service support give real confidence to both developers and end-users.”

The final tickets for this year’s 3DPI are available – act now before they are gone!

Printhead expertise to deliver unparalleled 3D printing accuracy and efficiency

Founded in 2015 in South Korea, Lincsolution specializes in the production of large-format SLA, FDM, and Binder Jet metal 3D printing machines. The company offers application-driven production services across various sectors, including automotive, defense, and consumables. Leveraging its proprietary machines, Lincsolution tailors its offerings to meet the specific needs of diverse industries.

Xaar Nitrox stands out for its operational efficiency, printing at a notable speed of up to 48kHz. With a user-friendly drop-in plug-and-print feature, the system ensures a quick setup, enabling rapid printing within minutes. Nitrox’s TF Technology and AcuChp contribute to consistent and uniform printing, ensuring reliable outcomes. This printhead’s versatility is notable, offering a wide application window and the capacity to handle various fluids, allowing for diverse printing orientations, whether vertical, horizontal, or on a robotic arm.

Additionally, Aquinox ensures reliability with TF and aQ Power Technology for an extended lifespan. Transforming productivity, it achieves speeds exceeding 100m/min, a 720dpi resolution, and a firing frequency of up to 48kHz, allowing for high fluid laydown. Introducing Ultra High Viscosity Technology, it jets high-viscosity fluids, enhancing opacity and vibrant colors. Moreover, it reduces water and energy consumption, offering a more sustainable printing solution.

John Mills, CEO at Xaar said, “We are delighted to have partnered with such an innovator as Lincsolution. 3D printing is one of the many exciting technologies for inkjet and the reliability Xaar printheads deliver make them the perfect choice for this growing sector.”

Additive alliances transforming various verticles

Skarv–Aker BP, Biesterfeld Norge As, and 3D printing company Roboze announced a partnership to advance the offshore industry’s digital shift. Enabling on-site production of crucial components and spare parts, the collaboration also involves the installation of the Roboze Plus Pro 3D printer on the FPSO SKARV in Norway’s Skarv field. This addresses the challenge of spare parts availability during maintenance. Meanwhile, Roboze and Ducati Corse extend their partnership into 2023, focusing on leveraging 3D printing in motorcycle racing.

Oerlikon AM and US 3D printer manufacturer 3D Systems announced a collaboration to scale metal additive manufacturing. Combining 3D Systems’ Direct Metal 3D printing platform with Oerlikon AM’s surface engineering capabilities, the partnership aims for a faster market entry in semiconductors and aerospace. Oerlikon AM acquired its fourth 3D Systems DMP Factory 500, deploying it at its North Carolina facility, marking its first use in the US.

Read all the 3D Printing Industry coverage from Formnext 2023.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows left to right: Dexter Yoon of Lincsolutions, Gareth Neal, Xaar Business Development Manager and Lincsolutions Chief Executive Officer, GeunSik Choi signing Memorandum of Understanding at Formnext 2023. Photo via Xaar.