Inkjet technology developer Xaar has signed an exclusive commercial partnership to manufacture NovoJet printheads for Berlin-based 3D printing startup Quantica.

Quantica’s NovoJet 3D printing systems are designed for high viscosity 2D and 3D printing. The partnership will see Quantica utilize Xaar’s expertise in inkjet printhead manufacturing and commercialization.

Whilst most inkjet printheads can 3D print materials around 20mPa•s, NovoJet can handle fluids at around 380mPa•s at jetting temperature. This equates to approximately 4000mPa•s at ambient temperature. Thus, NovoJet is compatible with a wide range of materials, including ultra-high viscosity fluids and high particle loads.

Set to be manufactured at Xaar’s Huntingdon facility, the first NovoJet printheads are expected to be shipped in Quantica’s 3D printers by the end of 2023.

“Our mission is to give customers the full freedom of production, and this partnership is instrumental in helping us achieve this,” commented Quantica CTO Ramon Borrell. “Xaar is widely recognised for the quality of its printheads, and this agreement enables us to focus on delivering the roadmap of innovative NovoJet 3D printers for high performance multi-material parts with full confidence the printheads will deliver for our customers and partners.”

Quantica’s 3D printing portfolio

Since its founding in 2018, Quantica has focused its research and development efforts on both its NovoJet printhead technology and advanced multi-material 3D printers.

Jointly developed with Xaar, the NovoJet printheads will be incorporated into Quantica’s NovoJet C-7 3D printer. Unveiled during Formnext 2022, this new multi-material desktop system is targeted towards research, feasibility studies, and small-scale custom production applications.

The company claims that its NovoJet systems allow for the production of multi-material products which possess high toughness, temperature resistance, conductivity, biocompatibility, and flexibility. Indeed, this new 3D printer can control up to 7 material channels, allowing for the production of parts with better mechanical properties, color fidelity, and aesthetics.

Looking to the future, Quantica is collaborating with industry partners to further develop its 3D printing systems for applications in dental, medical, electronics and R&D verticals.

Xaar gains access to Quantica’s high viscosity IP

In addition to the manufacture of NovoJet printheads, this agreement also sees Xaar gain commercial access to Quantica’s intellectual property (IP) in the jetting of materials at up to 400 centipoises (cP). This IP access will add to Xaar’s existing printhead and ImagineX technology offerings, which enable jetting up to 100cP.

Xaar claims that it will now provide the widest capability in high-performance material 3D printing to its OEM customers. This is said to meet opportunities for advanced manufacturing across various applications in the electronics, display, industrial coating, adhesive, and life science sectors.

“Our partnership with Quantica is a win-win for both our businesses,” stated Xaar COO Graham Tweedale. “The combination of our existing ImagineX technologies with the capability offered by Quantica’s IP will ensure Xaar offers the widest range of solutions in jetting highly viscous materials.”

“Similarly, Quantica will now be able to focus on the launch of its NovoJet 3D printers, with the backing of our expertise in manufacturing truly robust and reliable printheads,” added Tweedale.

Multi-material 3D printing

Last year Finnish bioprinting firm Brinter launched what it called the world’s first multi-fluidic multi-material bioprinting printhead. Designed for Brinter’s own 3D bioprinters, the printhead is aimed at research institutions and pharmaceutical companies. The printhead’s hardware can be modified with different temperature control and imaging options, making it compatible with a wide variety of materials.

Brinter highlights high-precision tissue engineering and regenerative medicine applications as key use-cases for their printhead. These include tissue damage repair, biological function replacements, and localized disease treatments.

Elsewhere, Japanese electronics firm Panasonic recently collaborated with scientists from Nanyang Technological University Singapore (NTU Singapore) and the Singapore Centre for 3D Printing to develop a new multi-material 3D printer. This 3D printer incorporates multi-wavelength high-power lasers for the production of smart, flexible, and wearable electronic devices.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

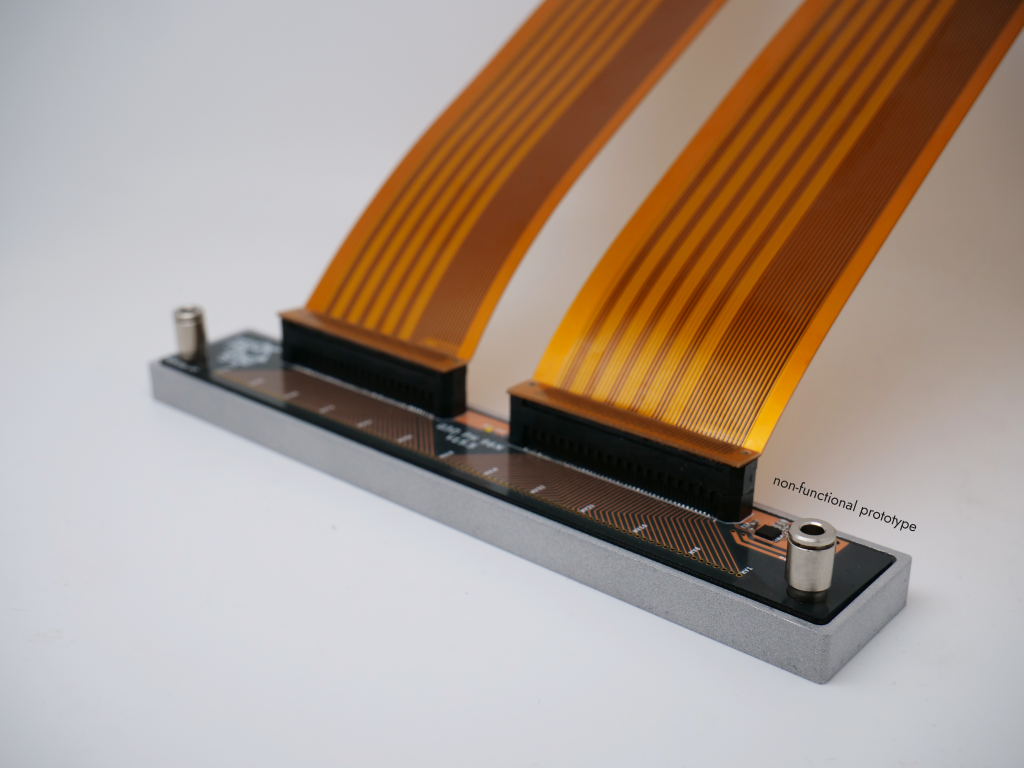

Featured image shows a Quantica NovoJet printhead. Photo via Quantica.