In a collaborative effort, Skarv–Aker Bp, Biesterfeld Norge As, and 3D printing company Roboze have achieved a significant milestone in the offshore industry’s digital transition.

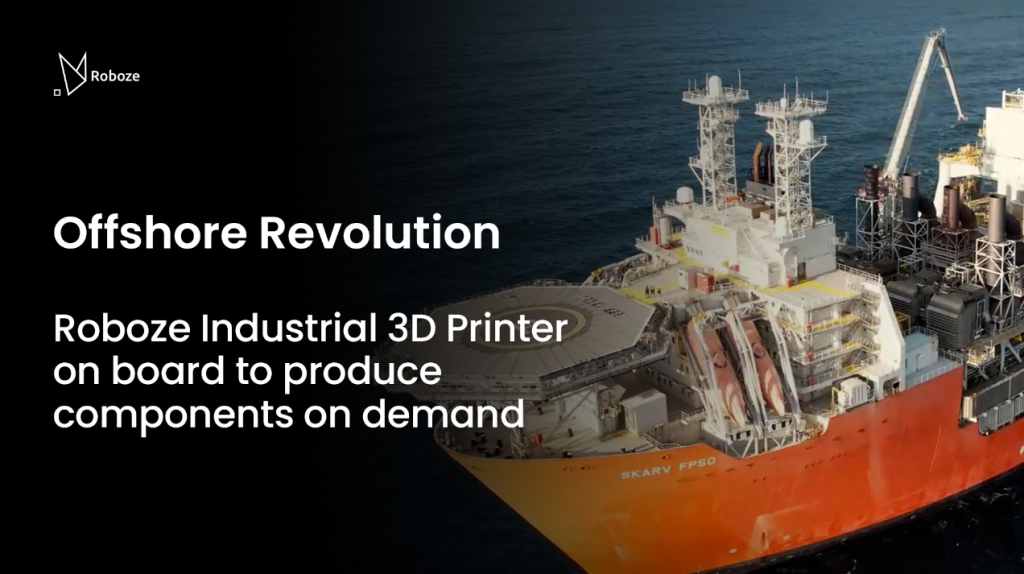

This partnership enables the on-site and on-demand production of critical components and spare parts. Central to this advancement is the installation of the Roboze Plus Pro 3D printer on board the FPSO SKARV, a specialized platform for oil and gas processing in Norway’s Skarv field. This strategic move directly tackles a longstanding industry challenge – ensuring spare parts’ availability during planned and unforeseen maintenance activities.

On another note, Roboze and Ducati Corse, the sports division of Ducati Motor Holding, have extended their partnership into 2023. This collaboration focuses on utilizing 3D printing in the motorcycle racing industry to drive technological advancement.

“Our partnership with Ducati Corse represents a perfect combination between technology and passion for innovation,” said Alessio Lorusso, CEO of Roboze. “We are excited to continue this collaboration and to contribute to the success of Ducati Corse through our advanced 3D printing solutions. We are confident that together we will achieve outstanding results also in 2023.”

Transforming the oil & gas industry with 3D printing

In the context of offshore installations, the availability of replacement parts is important, whether for planned or unforeseen maintenance activities. Prolonged shutdowns resulting from a shortage of spare parts carry significant financial implications, further aggravated by the constraints and costs associated with storage space. To address this challenge, the use of Roboze’s industrial 3D printing technology can assume a pivotal role. This approach involves maintaining a stock of only raw materials and producing on-demand spare parts precisely when they are required.

The video highlights the Roboze Plus Pro 3D printer’s crucial role in producing components from super polymers and reinforced composites for the offshore industry. It demonstrates how this technology is transforming problem-solving in extreme environments. Regarding challenges, corrosion significantly contributes to oil and gas installation shutdowns. Increasing the use of polymer components is an effective means to reduce this risk.

Producing components directly on the FPSO SKARV signifies a significant departure in the way maintenance and offshore supply management are conducted. This change enhances operational efficiency and minimizes environmental impact by reducing waste and enabling on-site production.

Last year, Roboze and industrial manufacturing firm Siemens joined forces to develop complete workflows for 3D printing industrialization. This collaboration involved combining their expertise to expand production opportunities in the energy, mobility, and aerospace sectors through various digitalization and automation projects. “For us, Siemens is an ideal partner to be even more present in these innovative sectors that want to start strategic digital transformation paths,” said Francesco Pantaleone, Vice President of Business Development at Roboze.

Helping motorsports teams gain a competitive edge

During the 2022 MotoGP season, the partnership between Roboze and Ducati Corse demonstrated its significance, enabling both companies to delve into technological advancements and achieve outstanding results. The application of industrial 3D printing and advanced materials played a pivotal role in producing custom, aerodynamic components, ultimately enhancing the performance of Ducati’s racing motorcycles.

In the upcoming 2023 season, Roboze and Ducati Corse are extending their collaboration, focusing on advancing 3D printing solutions for the motorsport sector. Roboze will contribute its 3D printing technology and novel materials, while Ducati Corse will leverage its substantial expertise in motorcycle racing to offer valuable feedback and precise needs for 3D printing applications.

Ducati Corse will utilize both the Roboze ARGO 500 3D printer, situated in Borgo Panigale, and the Plus Pro 3D printer, located in the paddock. This deployment will enable it to expedite the design and production phases, effectively reducing development time and enhancing the bikes’ performance. The capability to craft tailor-made, lightweight, and robust components is instrumental in preserving its competitive advantage on the racetrack.

Elsewhere, US 3D printer manufacturer 3D Systems and the championship-winning NASCAR team, Stewart-Haas Racing, announced a three-year technical collaboration to leverage Stewart-Haas Racing’s engineering expertise. Implementing 3D Systems’ ProX 800 stereolithography and Figure 4 Standalone 3D printers into its operations resulted in significant advancements in racecar speed and efficiency. This strategic approach is set to enhance Stewart-Haas’ “competitiveness across race days and in its ongoing commitment to innovation within the motorsports field.”

Who will win the 2023 3D Printing Industry Awards? Make your nominations now!

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Roboze’s Plus Pro 3D printer to produce 3D printed parts on-demand. Image via Roboze.