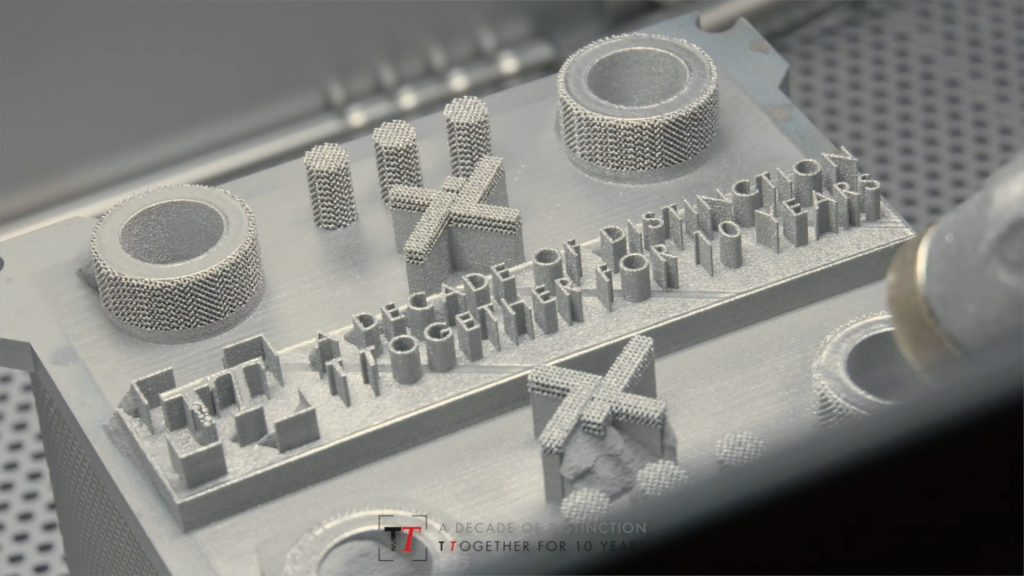

In 2007 Dr. Guido Grappiolo became the first surgeon to use a 3D printed trabecular titanium (TT) hip cup for a patient. Over ten years later Dr. Grappiolo speaks to Lima Corporate, the developer of the technology, and reports that the first TT implant is still going strong.

100,000 patients later

Trabecular titanium is a biocompatible material, made to mimic the mesh like structure (trabecula) of natural bone. Characterized by its honeycomb cell formation, TT implants are made using electron beam melting (EBM) technology, initially in collaboration with GE Additive company Arcam.

Since its introduction to the operating room over a decade ago 3D printed TT technology has been used to help approximately 100,000 patients through Arcam alone, though potentially hundreds of thousands more could have been helped by the implants made by other 3D printers.

A 3D print that could last a lifetime

Maria Pettersson is an orthopedic industry specialist at Arcam. Recently, in GE Reports, Petterson explained that it is common for people with a hip implant to get it replaced after 10 – 15 years. However, in an examination of the very first TT patient, Dr. Grappiolo believes that the implant “could also last for a lifetime.”

From Dr. Grappiolo’s point of view, “…this technology […] is becoming more and more popular. There is a large spread, and many companies in the orthopaedic industry have a strong interest in this technology.”

Lima has since expanded TT capabilites to make other implants, including shoulder replacements and partial knee replacements in collaboration with Materialise.

Luigi Ferrari, Lima Corporate CEO, comments, “This milestone is a great recognition for Lima and our supporting surgeons that believed in this technology 10 years ago and have continued this exciting path with us.”

“From this innovation to many others, Lima will continue to grow and develop solutions to assist orthopaedic surgeons in restarting the emotion of motion.”

For all the latest 3D printing in healthcare news subscribe to the most widely read newsletter in the industry, follow us on Twitter, and like us on Facebook.

Find your next medical career move on 3D Printing Industry Jobs.

Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your design for chance to win a 3D printer.

Featured image shows Lima and Arcam’s 3D printed hip cup holding ball and socket in place. Photo via Lima Corporate/Arcam