Smoby, a French toy manufacturer has collaborated with the IPC Industrial Technical Center for Plastics and Composites, and Belgian software provider, Materialise, to integrate metal 3D printing into toy production.

Together, the partners have created metal 3D printed molds which optimize the production of miniature Lightning McQueen cars, the protagonist of the animated Pixar movie, Cars. Jean-Christophe Bornéat, Project Manager at IPC explained:

“The main advantage of using metal additive manufacturing to produce tools for plastic injection molding is the possibility to create conformal cooling channels. These allow IPC to reduce the production cycle time and improve the part quality.”

Lightning McQueen 3D printed molds

Additive manufacturing has enabled consumers near and far to become makers, which in turn has disrupted the toy industry. Consumers can design and 3D print their own toys, while, industrial manufacturers are leveraging the technology’s tooling capabilities.

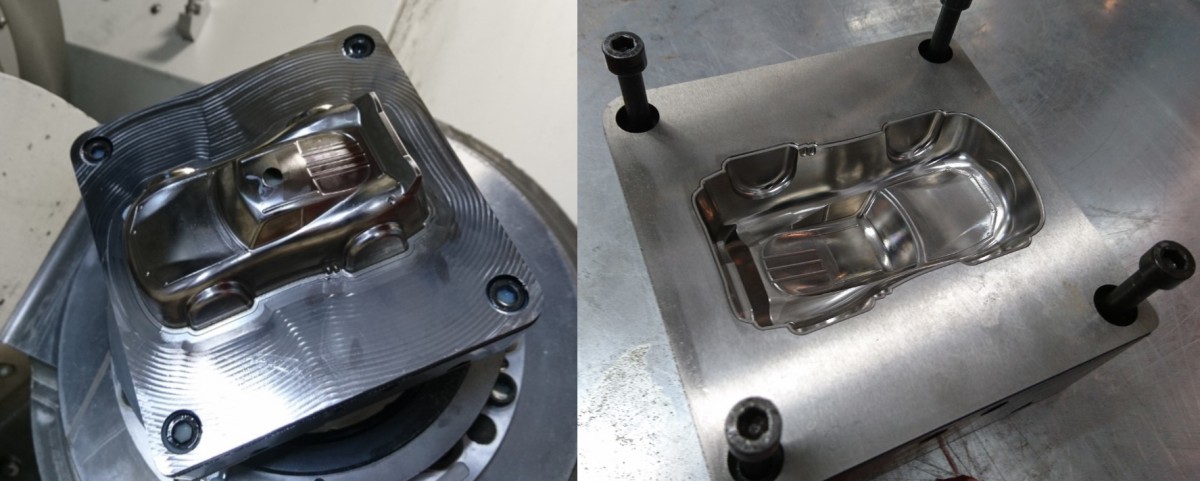

In order to create miniature versions of the Lightning McQueen car, IPC created a 3D printed metal mold. This was done as conventional small-series molds are time-consuming and costly to produce.

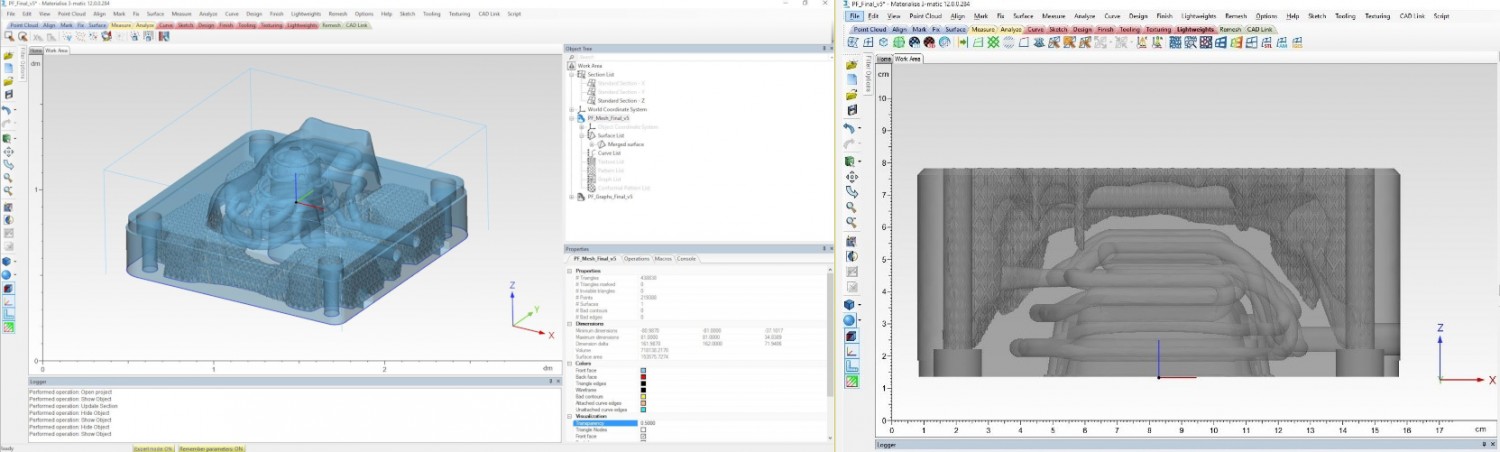

To improve the geometry of the mold, IPC replaced certain solid parts with a lightweight structure using Altair software. Then, the Materialise engineering team inserted this design into its 3-Matic software to smooth the surface and remove all artifacts.

Following this, the open space of the mold was filled with a lattice structure, cooling channels, and lightweight beams, taking into account all specifications for metal 3D printing. Bornéat added:

“Materialise 3-matic software helps us to replace bulk material with optimized lattice structures. This replacement reduces the global volume of the mold and so reduces the AM production time, the cost and the residual stresses on the part. These improvements will allow IPC to create larger molds with better return on investment.”

As a result of this collaboration, the production cycle of the toy was reduced by 50% and the lattice structure led to a material reduction of 12% for the upper part and 24% for the lower part. Furthermore, the optimized design is said to increases scanning speed and while the lighter weight of the mold enables the production of molds with larger dimensions.

3D printing and the toy industry

In 2016, Toys “R” Us stores throughout the UK collaborated with Taiwanese 3D printer manufacturer XYZprinting, to make desktop 3D printers more accessible to the younger generation.

Disney Research, are also developing animated characters with the help of 3D printing and cable driven actuation networks.

Following this, Michigan Technological University Professor, Joshua Pearce, stated in the research paper entitled, ‘Impact of DIY Home Manufacturing with 3D Printing on the Toy and Game Market,’

“It’s one thing to buy a toy from a store or get a commodity toy for your children. It’s perhaps more valuable to get that exact, specific toy that your kid really wants that you can either design yourself or download and customize on your computer and print at home.”

Submit your nominations now for the 3D Printing Industry Awards 2019.

Also, for the latest 3D Printing Industry news subscribe to our newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start in the new year? Visit 3D Printing Jobs to commence your new career.

Featured image shows a prototype of the miniature Lighting McQueen car created from 3D printed metal molds. Photo via Materialise.