Materialise, the Belgium 3D printing solutions provider, is tackling its largest SLA project to date by creating a life-size replica of the first mammoth skeleton ever displayed in Western Europe.

The skeleton is composed of 320 bones which have been scanned and digitally reconstructed. Now, Materialise will enter the fabrication process using its appropriately-named Mammoth Stereolithography 3D printers.

“Working on the first entire mammoth skeleton ever to be 3D printed has been a unique experience,” said Dr. Mietje Germonpré, Resident Paleontologist of the Royal Belgian Institute of Natural Sciences (RBINS) and Advisor on this project.

“3D Printing is increasingly proving to be an extremely useful tool in the field of paleontology, allowing us to study fossils without damaging the precious originals, and collaborate virtually on the same fossil with colleagues around the world.

Reviving the Ice Age

The Mammoth of Lier, named after the Belgium city it was discovered in, has been on display at the RBINS in Brussels for over 150 years. The remains of the adult mammoth were reconstructed by Louis De Pauw, Head Preparer at RBIN, who used carved wooden pieces to replace missing skeleton bones.

Materialise is now bringing the mammoth back home to Lier in a contemporary form with an entirely 3D printed skeleton replica. This will be mounted on a quasi-invisible internal structure and displayed in the city of Lier.

Paleontologists, scientists, and all those interested in our earth’s history have a stronger foundation in studying the progression of animals and environments thanks to the immortalization of ancient creatures through 3D printing.

London’s Natural History Museum (NHM) has demonstrated additive manufacturing preservation capabilities with its 3D printed replicas of a Diplodocus dinosaur skull. Similarly, researchers from MIT used a Kinect 3D scanner to preserve the famous tyrannosaurus rex fossil displayed in Chicago’s Field Museum.

Printers to the bone

Reconstructing the Mammoth of Lier, presented several ‘bones of contention’ as translating the original fossils into 3D printed models was not an easy task.

“The scale of the project is challenging, particularly because we had to bring different experts together, including engineers, paleontologists, and finishing specialists, and align our vision of the finished model, all while meeting tight deadlines,” said Gertjan Brienen, Project Manager at Materialise.

Yet, in collaboration with their RBIN resident paleontologists, Materialise, with the Materialise Magics and Materialise 3-matic software, was able to achieve the highest degree of anatomical accuracy. Brienen added:

“The original mammoth skeleton is missing a few bones, including its left tusk. We mirrored the right tusk and recreated it in Materialise 3-matic to achieve a more precise replica than the wooden tusk that was used to complete the original skeleton. This means the 3D-printed mammoth will be more scientifically accurate than the original.”

Materialise also sought the tooling expertise of its daughter company RapidFit, to create carbon interior structures inside the plastic bones, which will aid in the assembly of the entire mammoth skeleton. This resulted in a lightweight, solid structure weighing at a total of 300 kg.

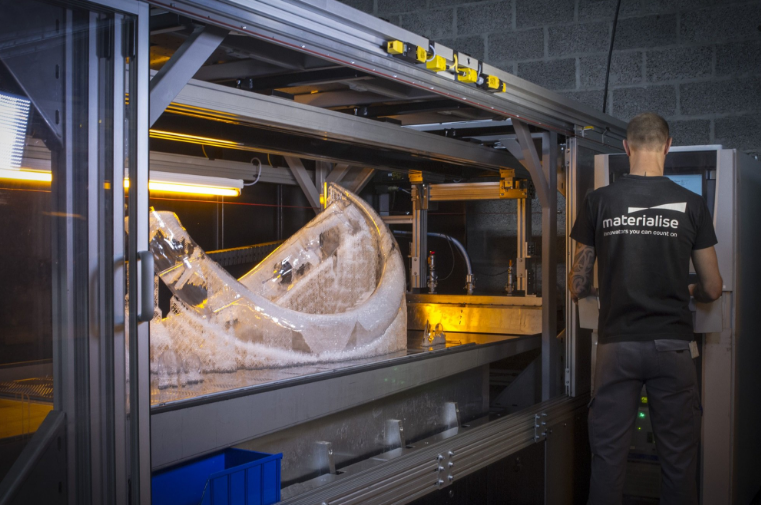

With a printer bed dimension of 220x70x80, the Mammoth Stereolithography 3D printer will fabricate the bones in approximately a month, applying 1/10th of a millimeter of resin at a time. The 3D printed bones will then be finished, painted, and assembled to resemble the original skeleton.

Following its completion, the 3D printed mammoth will be on display in the city of Lier in October.

Keep up with this project and other 3D printing ventures by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows Materialise employee holding a 3D printed mammoth bone. Photo via Materialise.