The Liberty Bell is famous for its crack, and not just the type you find in the park after hours. No, after the bell cracked in the early 19th century, the fissure itself has become an iconic part of the monument. So, when artist Jeff Koons turned to the Maryland-based 3D scanning firm Direct Dimensions to recreate the Liberty Bell, he didn’t want to use the pre-cracked version they had modeled back in 2002-2004. Instead, Koons wanted to recreate the monument as-is, like it or lump it.

In 2006, Koons approached Direct Dimensions to help him make an exact duplicate of the Liberty Bell. It’s now 2014 and the artist and his massive team have finally completed the task of, as Vanity Fair aptly put it, manufacturing “a near-perfect replica of an imperfect object.” Title Liberty Bell, the representation of a representation of the concept of liberty debuted at the Whitney Museum this month.

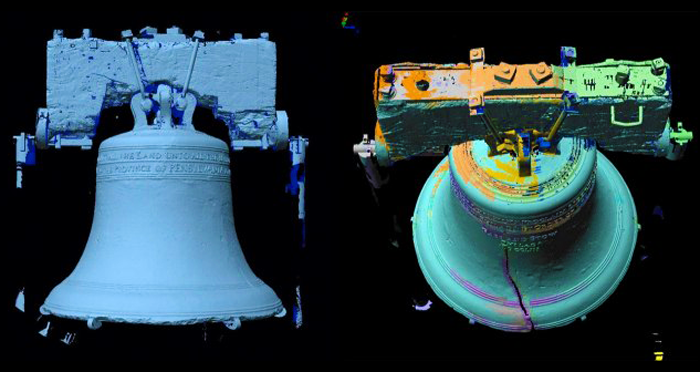

To recreate the monument, Koons enlisted his team of 128 people, according to VF: “64 in the painting department; 44 in the sculpture department; 10 in the digital department; and 10 in administration”, plus outside specialists, consultants, and MIT’s Center for Bits and Atoms. After hours, the Direct Dimensions team performed scans of the bell, capturing point cloud data to create a 3D model. To achieve accurate detail, the CAD data was handled with a variety of software tools, with some data being so complex as to take up to a year to process.

When he began the endeavor in 2006, it wasn’t feasible to convert a 3D model directly to a computerized milling device, but the technology has improved, allowing German metal-working company Arnold AG to mill a copy of the bell. The wooden yoke that holds the bell was milled by Walla Wall Foundry from red elm harvested and dried by Dan Terbovich, of Horizon Wood. And 18th Century wood finishing experts Olaf Unsoeld and Cornelius van Horne developed a patina to replicate the finish of the original bell.

In addition to the more obvious components, throughout the monument are a series of metal parts, including an internal structure that could only be studied through historical drawings. To manufacture the 257 metal parts, including the bell’s 100-piece clapper, a wrought-iron blacksmith, Tim Miller, was hired.

Recreating the bell’s patina involved painstaking analysis and painting. The bell’s color composition was broken down into a grid made up of various RGB values, which were then painted with the help of numerous layers of laser-cut stencils and expertly mixed paint. After three layers of paint were applied, a “hand-painter” sharpened the coats of paint with a fine brush.

Most of us would probably have finished our versions in less than a month, though the results would all be papier-mâché and wouldn’t look much like the original. Koons and his team, however, performed this 8-year, highly-detailed recreation as “a moral commitment to the viewer.” Personally, as a viewer, I’m conflicted about the forgery. On the one hand, I like super accurate replicas of real things, as they symbolize, for me, the possibility that life itself is a simulacrum, a copy of a copy of a copy of an original that may never have existed. On the other, I’m not sure if Koons is an artist or more of a director/supervisor who operates a factory of artists working to execute talents that might be better spent elsewhere. But that’s art for ya!

As a viewer, what do you think?