On-demand additive manufacturing start-up Ivaldi Group has announced that it will be participating in the SAP.iO Foundry New York Fall 2020 virtual accelerator program.

The program will see the company working with enterprise software developer SAP to formulate real-time business intelligence regarding the digital management and distributed manufacturing of spare parts. Ivaldi will then have the opportunity to provide SAP’s extensive customer base with its insights, generating business for both parties involved.

The rise of digital inventories

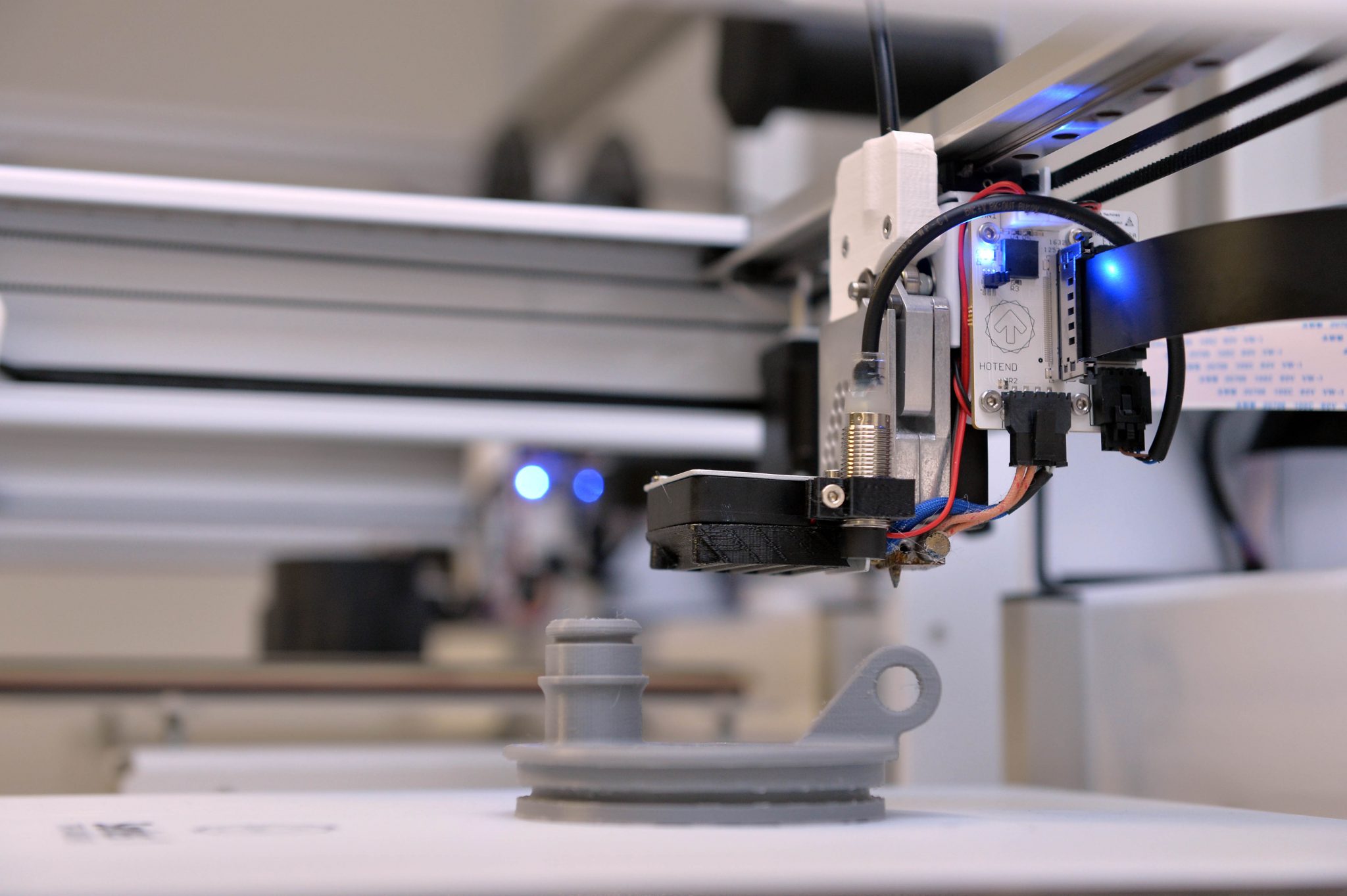

Ivaldi has spent the past four years helping its manufacturing customers transform their physical inventories into cloud-based digital storage spaces, which can then be 3D printed locally on-demand. The company believes that for a growing number of industries, managing files rather than tangible parts can have environmental benefits, create jobs in the local area, and can be great for the sole purpose of cutting logistical costs.

Espen Sivertsen, CEO of Ivaldi Group, explains: “We’ve found that the first step is for customers to understand what parts they have that can be taken digital and what the business and environmental case for each part is. So we’ve built software that helps them do so.”

Now, through the SAP.iO program, Ivaldi will utilize machine learning and natural language processing techniques to further develop its system to ensure it is capable of automatically analyzing spare part inventories and providing digitization insights. According to SAP, these actionable insights will be “crucial for any [SAP] customer dealing with spare parts” as many of its clients are looking to make the digital leap. This year in particular, the elevated levels of supply chain disruption have reportedly hiked up carry costs while increasing spare part shortages.

Stefani Pellinen-Chavez, COO of Ivaldi Group, adds: “This is a significant milestone for the supply chain industry. Up until now it has simply not been possible for companies dealing with spare parts to get accurate business intelligence on what parts to take digital. SAP and Ivaldi are now changing that. We aim to transform the spare parts supply chain.”

Transforming the spare parts supply chain

Related systems have already successfully been implemented in industries such as automotive, mining, and maritime where companies tend to have high transportation and storage costs on large parts.

Just last year, Swedish infrastructure and mining equipment manufacturer Epiroc introduced a project focused on 3D printing spare parts for the heavy machinery found in the mining industry. The company has stated that additive manufacturing will allow firms to transfer files around the world in minutes, with production taking place as and when needed.

Elsewhere, the Indian Navy recently partnered with Indian 3D printing service bureau think3D to help 3D print spare parts on demand for both its on- and off-shore naval equipment. The availability of spare parts has reportedly been a recurring problem for the Indian Navy in recent years due to the use of old, imported machinery – an issue this partnership aims to remedy.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the local 3D printing of spare parts with Ivaldi. Photo via Ivaldi Group.