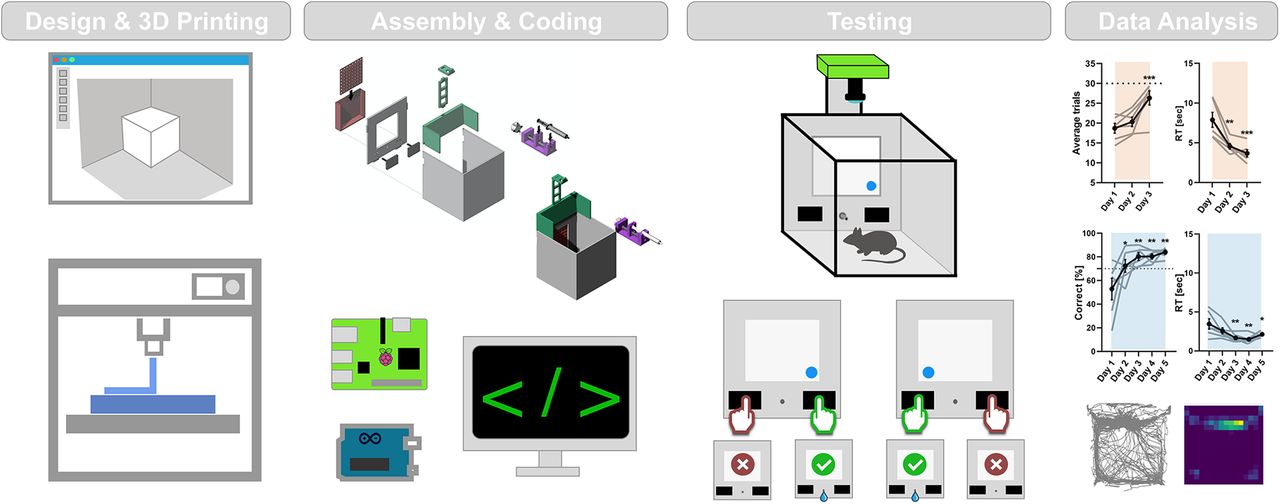

A team of researchers from the University of Florence and the Institute of Neuroscience in Pisa have developed a 3D printable contraption capable of conditioning mice to perform a certain action. The researchers cite the device as being representative of a “good balance between performance, cost, and versatility”. Since confirming its efficacy in psychological experiments, the team intends to move onto drug trials, where the device will be used to investigate the learning and memory side effects of various therapeutic interventions.

Operant conditioning

Operant conditioning is a classical technique in behavioural psychology whereby an animal is taught to perform an action to receive a reward – usually a sugary treat. Using operant conditioning, researchers are able to determine learning curves and measure reaction times. These metrics are deemed to be a great representation of general cognitive ability and can be used to investigate the side effects of diseases and their treatments.

Commercially available operant conditioning devices already exist (there’s a market for everything apparently) but they’re rarely customizable and tend to be fairly costly. The 3D printable, automated open-source design is more than affordable, totaling only 163€ for the materials. This includes all of the filament, LEDs, a Raspberry PI, a camera, a buzzer, motors, and an assortment of wires.

3D printing for psychology

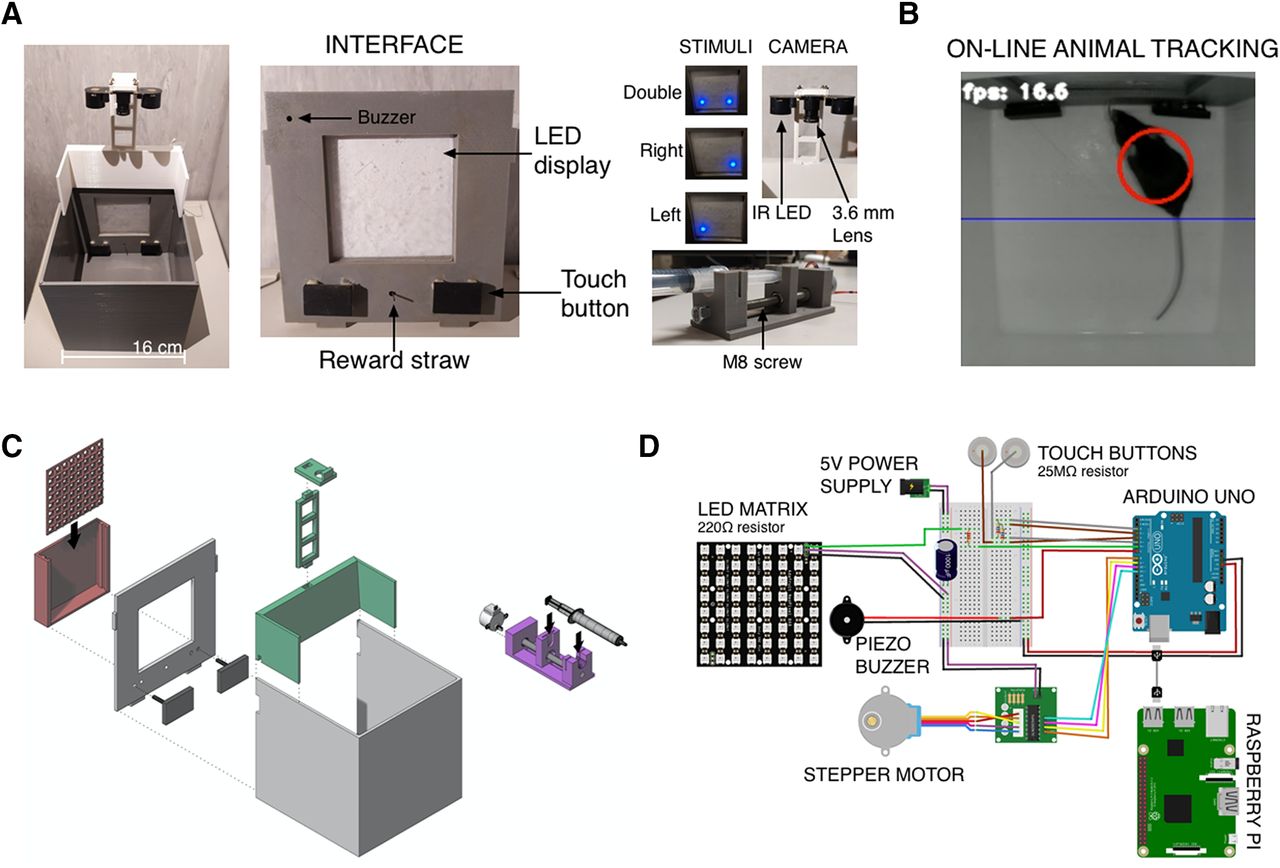

The device was designed with reproducibility in mind, so that laboratories around the world could download it and use it for their own experiments. The device is also easily customizable, allowing it to fit the specifications of a number of different experiments. The main arena of the conditioning box measured 160 x 160 x 160mm and was printed in PLA on a Kentstrapper Verve 3D printer. The researchers included a slot for a camera so the position of the mice could be monitored at all times.

The front wall of the arena comprised a printed LED display, two printed touch buttons, a printed reward straw, and a buzzer. The LEDs indicated which of the two buttons should be touched to release a sample of 1% condensed milk from the reward straw while the buzzer produced a 3300Hz tone when the mice touched the correct button.

The team successfully trained six mice over the course of the experiment, all of which showed stereotypical learning curves. After two days of conditioning, the mice reached an average of 70%+ button accuracy. Looking at their data from the experiment, the researchers concluded that their design would be a suitable alternative to today’s leading commercial devices, enabling science to excel without the unfortunate price tag.

Further details of the design of the device can be found in the paper titled ‘3D Printable Device for Automated Operant Conditioning in the Mouse’. It is co-authored by Raffaele Mazziotti, Giulia Sagona, Leonardo Lupori, Virginia Martini, and Tommaso Pizzorusso.

One of the areas where 3D printing truly shines is in the development of educational and research equipment. Recently, a team of researchers from the University of Bath developed and released an open-source design for a “laboratory-grade” microscope, with the 3D printing materials costing just $18. The OpenFlexure microscope is fully automated, features motorized sample positioning, focus control and a precise mechanical stage.

Elsewhere, in Indiana, a pair of researchers released a paper detailing the design and construction of a 3D printed polarimeter for use in chemistry classes. The device is capable of measuring the angle of rotation of polarized light after it has passed through an optically active substance or chemical.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the assembly of the device and how it works. Image via University of Florence.