This week marks the 10th anniversary of the RepRap project. At 3D Printing Industry we’re interviewing some of the earlier pioneers and leading figures in the open source and FFF 3D printer world.

Vik Olliver was the first RepRap volunteer. He is a widely recognized Open Source expert and also brought skills in hardware and software development to the project. It was Vik Olliver who first had the idea of using PLA as material in the FFF 3D printing process. In this article Vik Olliver talks about the history of the RepRap project, some of the key developments and the future of self-replicating nanomachines.

Michael Petch: How did you come to be involved in the RepRap project?

Vik Olliver: Long story. In the mid-90’s I set out to carve a piece of culturally significant New Zealand greenstone; Pounamu. I made a 3D model of the intended piece and just kept on doing 3D modelling. Before long I was modelling planets, spacecraft, the moon and so forth – then a chap from NASA saw my work and wanted to use it as a backdrop for a private manned lunar mission proposal: Project Artemis. His foreground model was tacky, so I modelled it properly and that led to me designing real satellites, lunar spacecraft, life support systems etc. and working on a return to the moon.

Realising that you can’t take all the spares for life support with you I began designing a machine that could make the parts, and the parts for itself. Whole reading New Scientist magazine, I saw an article by Adrian proposing a replicating machine and realised “Yeah, one of those would be really handy on Earth too.” I contacted Adrian and we had a discussion in which he suggested that squirting plastic was the way to go.

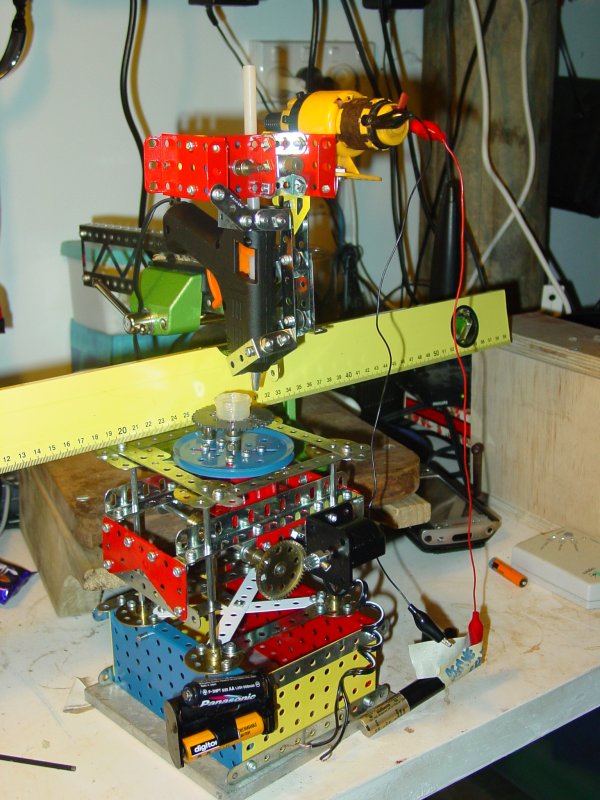

I had a free week coming up, so I drew on a lifetime’s supply of Meccano and my daughter’s supply of glue guns (sorry darling, Daddy will get you new ones) to create the first prototype in my workshop – little more than a motorised glue gun on a stick hanging over a self-lowering turntable. It could however print a short tube from readily available materials in an unregulated workshop environment. I presented this to Adrian and became member #3 on the team.

Michael Petch: Please can you tell me a little about your role in the project?

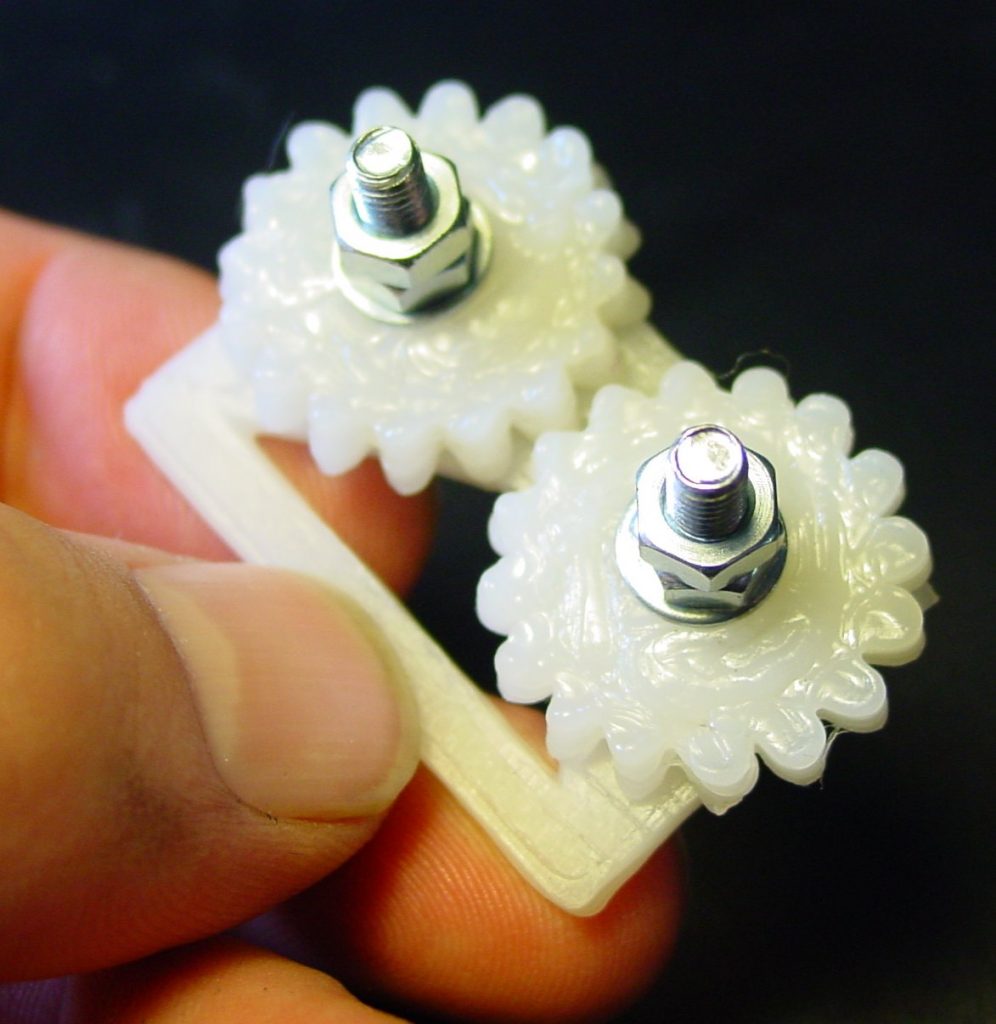

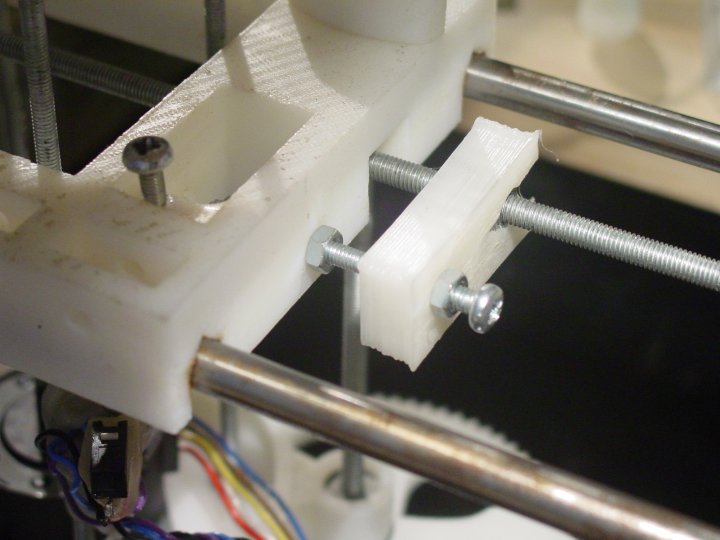

Vik Olliver: A tinkerer and hacker, occasional documenter. I designed stuff, built prototypes from scrap, and did a lot of adapting the designs to use everyday materials and parts. Not everything worked, but finding out what does and doesn’t quickly is a necessary part of the game. I made the first 3D printed part on a prototype to replace a tooled part in the prototype. I designed a screw-driven extruder, ways to mould gears, experimented with bed materials and coatings (blue tape is one of mine), and filaments – I made the first PLA filament. I set up a company Diamond Age Solutions Ltd. to sell the filament to developers.

I built the first “Child” printer – one assembled from the parts printed by a 3D printed printer; being able to assemble things quickly and bodge the parts on the fly helped. i.e. Replacing (then) unobtainable drive belt with the ball chain used to tie down bath plugs. I designed a lasercut acrylic version of the Darwin. My super power is probably debugging though 🙂 I have an understanding of things from mining the copper and silicon to programming the finished computer, and can trace bugs through hardware and software. I turned the fact that things always break around me into an asset… I also travelled a lot and evangelised to the Open Source community and Maker movement.

Filament was a pain because nobody supplied what we needed. Adrian bought a big bag of CAPA aka Polymorph aka Friendly Plastic. This softens around 60C and you can shape it by hand. We rolled it between sheets of glass with a knitting needle as a spacer to produce short lengths of filament, and welded them together with a lighter! With practice, as at a live demo in Vienna, I could make filament faster than the printer used it. However, after I’d got PLA filament made by collaborating with a nice chap called Allan at a local plastics factory (Imagin Plastics, Auckland. Still selling it.) our life became a lot easier…

Michael Petch: What are your thoughts about how RepRap has developed over the past decade?

Vik Olliver: RepRap evolved from the first proof of concept machines to the kits we know today in relatively short order. They evolved pretty much as we expected them to, but the proliferation of support from Chinese companies to independently produce the Open Sourced electronics needed to build the was an unexpected bonus. These kits and parts encouraged further experiment as they could be easily adapted thanks to their open source nature.

This led to the creation of multi-head printers, the fast delta configuration designs, and various versions of printer with continuous belts as print platforms. Lots of innovation, most of it Open Source, and thus those designs will drive further evolution. Kudos to Catalsyt IT Ltd of Auckland who employed me remotely and let me have one day a week (“Google Time”) to run an Open Source project. RepRap of course.

Makerbot was started by us to provide a way of printing parts for 3D printers and bootstrapping the process. The takeover management (my thoughts about the matter are unprintable in family publications) closed the design off from the community and while they made some money they basically stopped innovating beyond the basic design. Meanwhile, laboratories wanting to make custom printers for, say, printing body parts, would use RepRap-based machines for their developments because the workings were documented, easily modified, and supported by an enthusiastic community. RepRap-based designs still hugely outsell Makerbots.

The RepRap design is printing a lot more materials than we started with, and has been adapted to wield lasers, routers, pens, knives, inkjet nozzles and pasta extruders. These are used to produce more Open Source tools, which get folded back into the process to produce more exotic machines.

At the other extreme, kids scavenging the e-waste tips we ship off to Togo are building their own RepRap-based 3D printers from the scrap, now they know it can be done.

It’s fun to watch evolution in action.

Michael Petch: Are you still working with 3D printing, what are you currently working on?

Vik Olliver: Not directly. I’m trying to persuade people to do the same thing we did to RepRap on a much smaller scale – individual atoms. The ultimate aim is self-replicating nanomachines, but getting there is tricky. This means we’ll have to do the same thing as the RepRap project did – cheat. We used existing precision threaded rods and belts, took impressions to generate gears, and used common motors. Nanotechnology will have to bootstrap from existing crystal structures, proteins, and so forth instead. Lots of great work being done at the Technical University of Munich (TUM). As with RepRap, trying to convince people this is not mad is half the battle!

Eventually the chemistry of ever more complicated materials will be able to interact with the smallest machines we can make to provide manufacturing capability all the way from the macro world to an atom. We will have digitised matter, and at that point you can make just about anything for just about nothing.

While pursuing this dream, I farm olives, support the local Fab Lab workshop, and develop keyboards for disabled people in China.

Michael Petch: What is your perspective on the state of Open Source in 2018 and is there still a need for OS projects?

Vik Olliver: Open Source is in pretty good shape, it has a huge army of developers and testers, and they’re more connected than ever before. What’s not in good shape is its adoption. Bureaucracy was invented to pass the buck, and proprietary development houses have played on a fear that it may be difficult to pass the buck onto an anarchistic crowd of diverse individuals. Those who actually know how things work will know that Open Source development is not like that, but the ignorance is there and can be readily manipulated.

Still a need for OS? That’d be a “Hell Yes!” because it is the best way to collaborate and innovate. It’s 2018, Microsoft’s notepad app is 35 years old, and it’s only just supported UNIX and MacOS line endings. Proprietary companies spend huge amounts of money – our money – shaping our governments, commerce and society to their own ends, basically so we give them even more money. Then they stick it all on their own servers, call it “The Cloud” and charge us rent for the privilege! They can do this because they create their own lock-in: You can’t drop Facebook because all your friends are on Facebook, right? Even if they’re selling your digital soul.

Basically Open Source technology is the only way we’ll end up as citizens in this technological world, rather than as serfs.

Michael Petch: What is 3D printing currently missing, what would you like to see?

Vik Olliver: Multiple heads printing simultaneously to increase speed and/or use more materials. It could be done using asymmetrical delta printers that overlap a workspace. Incline that workspace to 45 degrees, and stick a moving belt under it for a base and you can print infinitely long objects really quickly.

Smarter materials. It’s still tough to print a circuit, let alone a functioning electronic component. Materials are needed that engage actively with their surroundings rather than passively: repeatable movement, changes in state, changes on volume, self-healing, self-organisation. For your average RepRapper not much has changed in the feedstock department since I created the first PLA filament.

More education on all levels. Too often I see schools with 3D printers gathering dust because the staff don’t know how to use them. I see students being taught “3D Printing” in the same way that you can teach “Computing” by showing students how to use a spreadsheet. Kids need to experiment with the process and the materials, not just learn how to print a plastic windmill.

Michael Petch: Do you have any other RepRap thoughts you’d like to share?

Vik Olliver: When we all got our first Darwins working, we each printed out “minimug” cups, and toasted each other 🙂 It was fun listening to people telling us that we couldn’t possibly make a machine that could print itself, when we had one in the workshop…

I once had to explain at NZ Customs and Excise HQ that Maurice Williamson the current minister’s assertion that 3D printers would print gold, gems and drugs so they should be restricted was complete nonsense, and pointed out that even if they could this would not be a bad thing.

We always knew that people would use the RepRap for good and evil, as every technology has been. People want to use any new technology to produce weapons, sex toys , and drugs paraphernalia. But Adrian pointed out that given something like the internal combustion engine, people tend to build more ambulances than tanks. In recent mass shootings in Palestine by the IDF, I noticed that the Palestinians are not 3D printing guns, they’re 3D printing tourniquet kits. They’re using RepRap-derived Prusa printers and local recycled filament. They’re making them in the quantities they need, breaking a blockade, and making sizes that fit children because they treat more of them for gunshots than adults. They’re evolving the design so it can be deployed on the run or under fire, and it’s Open Source so others in similar situations can use it.

There’s Dr. Michael Laufer and his cohort of DIY medical activists at Four Thieves Vinegar Collective, 3D printing affordable versions of the ludicrously expensive (and patented) Epipen, and various other medical devices. Again, providing necessary medical devices as Open Source to those who are in greatest need but have no money to interest pharmaceutical companies.

Simple biochemical reactors are being printed. Soon there will be little DIY “drug factories” popping out of printers. The authorities (possibly helped by aforementioned pharma) will decry the devices as being production systems for meth and heroin, while there is much need for asthma control and heart medication that currently goes unfulfilled because of cost and access. It’s tanks and ambulances all over again.

We didn’t just build a 3D printer, we built a community that’s still going.

The RepRap 10th Anniversary series continues

You can read more in the RepRap 10th Anniversary series here. Make sure you don’t miss the forthcoming interviews with other RepRap pioneers, subscribe to the 3D Printing Industry newsletter and follow us on social media.

Want to work in additive manufacturing or looking for a 3D printing job? Sign up for our free jobs service now.

Featured image shows Vik Olliver and his RepRap 3D printer. Photo via Vik Olliver.