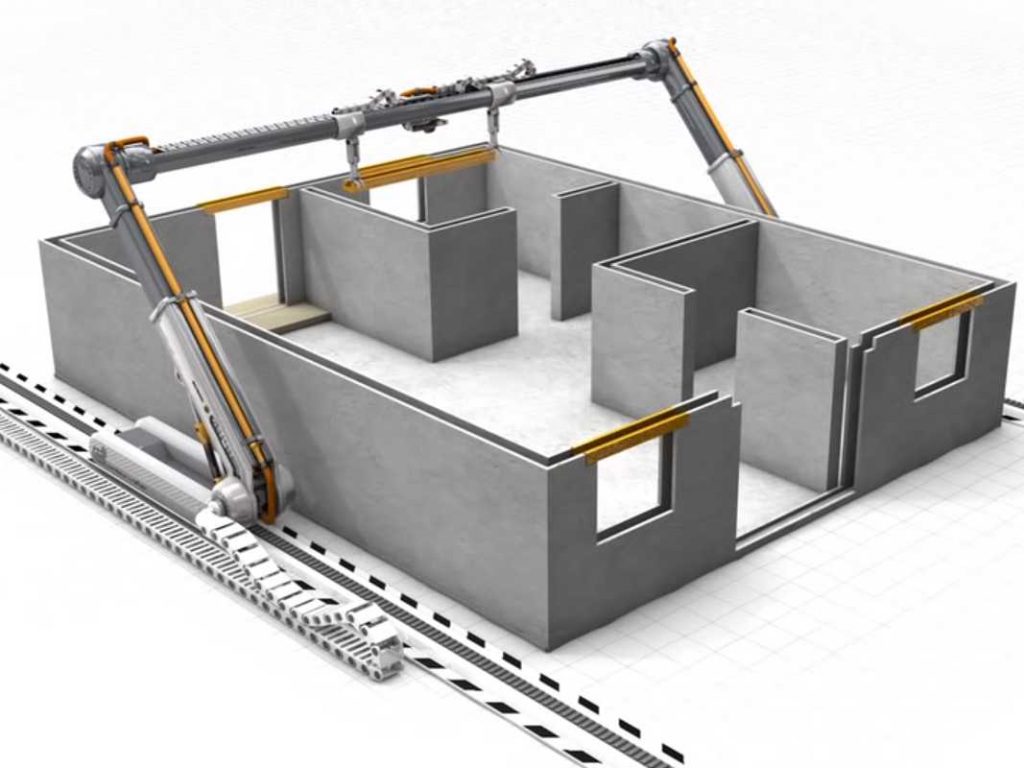

In 2017, 3D printing for construction has started to gain more coverage. While some of the projects using 3D printing to make buildings may never develop beyond the well polished renders, and highly shareable video content, other enterprises are advancing with tangible results.

That’s not to say the technology is new. In 2015, I visited Shanghai and saw concrete 3D prints from Winsun – a project drawing on much earlier work done by Berok Khoshnevis of Contour Crafting.

More recently, 3D Printing Industry visited France to see how reseller Machines-3D and Construction 3D are progressing. Other enterprises hoping to capture the markets enthusiasm for buildings on demand have been more opaque. And in some cases their claims are highly dubious.

By bringing experts and interested parties together at events like the recent 3D construction printing conference in Copenhagen, projects can be evaluated and foundations checked. I caught up with Henrik Lund-Nielsen, CEO of 3D Printhuset and the organizers of the recent Copenhagen conference.

Lund-Nielsen is aware of the scepticism from the traditional construction industry, and some of the tech media. The recent completion of 3D Printhuset’s, Building on Demand (BOD) in Nordhaven, Copenhagen, is one way to answer, and successfully demonstrated the application of 3D printing technology for building.

Henrik Lund-Nielsen: Yes. At our conference on Nov 30 during the panel debate the participants, coming from 3D Construction printing companies as well as the conventional construction industry were asked by the conference moderator, if in 5 years there would be 1000’s of 3D printed buildings globally.

ALL participants in the debate confirmed.

I can add that we on a small scale are already seeing signs of that this prediction is indeed true: As a consequence of our demonstration project, The BOD, Europe’s first 3D printed building, we are now in discussions with multiple site owners, locally as well as abroad, about doing buildings from them, ranging from a single building up to 14 buildings in one project. One of the projects is for refugees housings.

3DPI: What are some of the major challenges faced 3D printing for construction?

HLN: There are multiple!

We are still very much on the start of the learning curve. One of the main challenges for us in our project was the handling of the materials that made up the recipe we used, where we had a high share of recycled content. We had virtually no problems with the 3D printing itself, but getting the materials in the right shape and form to the printhead was a challenge. So materials handling and recipes is one of the challenges.

Similarly obtaining the permit for the load bearing structure is not easy when you start doing buildings with organic shapes (like we do in The BOD, where we even printed wall with wave forms) as the authorities and formulas for calculating the statics (the load bearing capability) are used to only handling straight walls etc.

3DPI: Forerunners such as Berok Khoshnevis have worked on construction 3D printing for many years now, why do you think the industry seems to be expanding rapidly at the moment?

HNL: Because now evidence in the form of actual buildings done with the technology is starting to appear. That helps to open the eyes of people, and it helps with getting funding, like Khoshnevis who was funded by an Austrian conventional construction company.

3DPI: The 3D printing for construction sector has seen a number of new entrants during the past 12-18 months, some with very different background from traditional construction. What are your thoughts about this?

HNL: I think that new entrants need to have competence in one of two areas to succeed. Either they have to come with serious experience and competence from conventional construction business or they need to have experience and competence from 3D technology, either from 3D printing or robotics. If one of these two competences are not present, I do not think they will succeed.

3DPI: Which construction projects do you see as having the most potential for using 3D printing?

HNL: Right now most focus in on small single buildings in one storey, like private houses for instance. I think we will very quickly see that also other types of buildings can be made with 3D printing, including multi storey and much larger buildings. However, to predict which type will be the most potential is too early, simply because too little experience with the other types of buildings exist presently.

Let us know if any of the recent 3D printing construction projects should receive an award at the 2018 3D Printing Industry Awards. Make your nominations now.

More information about 3D Printhuset is available here.

For all the latest 3D printing news, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.