Our series to mark the 10th anniversary of the RepRap project continues with insights into the 3D printing software world.

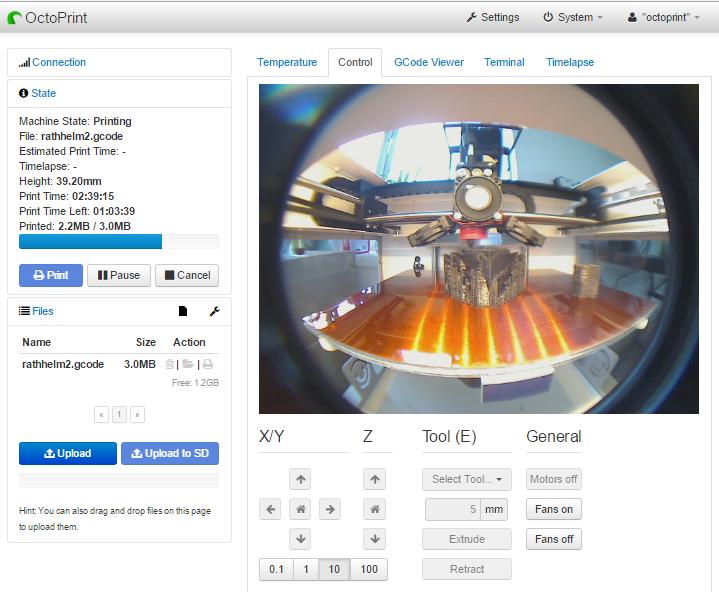

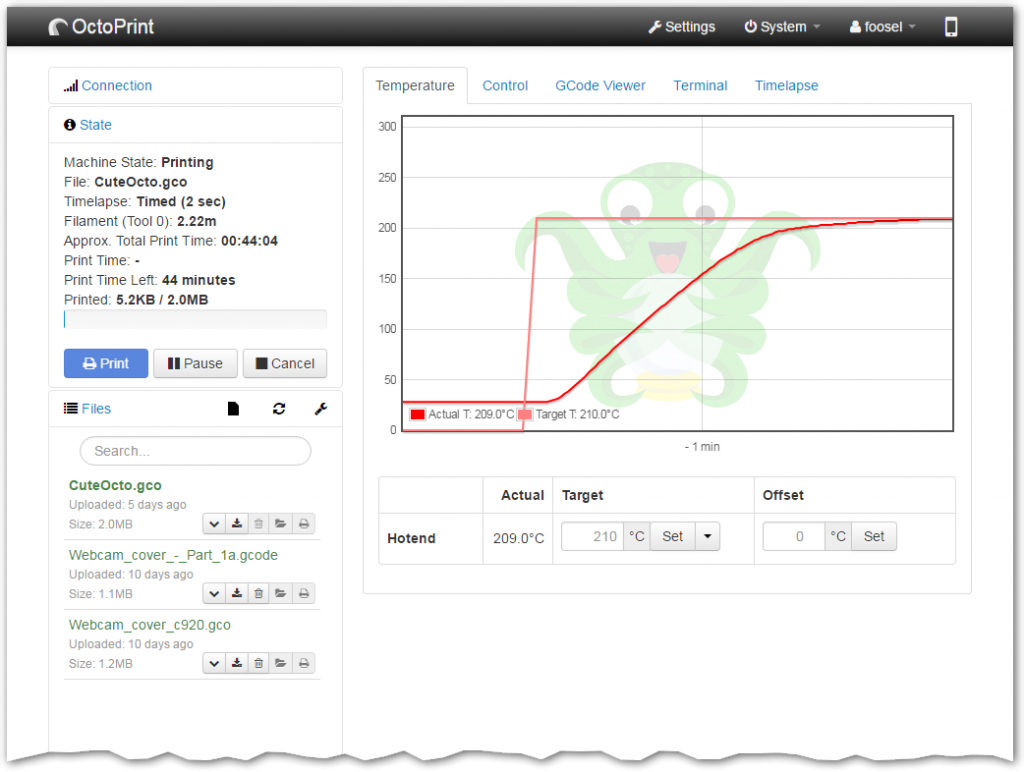

Gina Häußge is the founder and main developer of OctoPrint. OctoPrint is a highly extensible and powerful tool that allows a user to control and monitor 3D printers remotely.

Gina Häußge first encountered 3D printing and the RepRap project at the 2009 Hacking at Random event in the Netherlands. Several other attendees would also go on to become influential figures in the 3D printing industry and 3D printers soon became a regular feature at similar conventions.

In this interview Gina Häußge discusses the benefits of Open Source, the importance of history and how she would like 3D printing to improve from the software perspective.

Michael Petch: How would you describe the importance of the RepRap project?

Gina Häußge: RepRap is what turned 3D printing from a walled garden technology into a mass market phenomenon, available and affordable for hobbyists. Without it, 3D printing would probably still be a technology unavailable to anyone but companies capable of affording the expensive commercial machines and we would have seen a lot less innovation in the market. These days basically everyone has heard of 3D printing thanks to the hype that surrounded it for a while – without the RepRap project pioneering a lot of what made such a mainstream presence possible, that would not be the case.

Michael Petch: How does RepRap relate to you now?

Gina Häußge: While none of my current printers are self replicating, they are all relying on RepRap technology at their heart, be it community developed software, firmware or hardware. I don’t think there a lot of consumer 3D printers on offer today for which this doesn’t hold true, and it saddens me a bit that a lot of people owning a 3D printer today know nothing of the history behind it.

Michael Petch: What is your perspective on the state of Open Source in 2018 and is there still a need for OS projects?

Gina Häußge: There definitely is a need for OS projects. In fact, I think the past couple of years the importance of Open Source has only grown as companies across the globe are seeing the benefits of sharing knowledge instead of reinventing their own wheels over and over again and have started to contribute more actively.

Especially in the field of consumer 3D printing, everything relies on Open Source – be it firmware, host software, slicers. And the CAD packages are also catching to their commercial and closed source competitors.

Gina Häußge: I’d certainly say that the high availability of heated beds and auto leveling on consumer 3D printers has done a LOT for printer reliability. Add to that a large selection of printable materials these days – these days there are way more options than just ABS and PLA, and people get incredibly creative with that. Multi Extruder setups aren’t as wide spread and still have some kinks to iron out, but I’d say that is also something that should be mentioned here.

Michael Petch: What is 3D printing currently missing, what would you like to see?

Gina Häußge: This is a very technical and special point of view caused by my daily work on OctoPrint but: a coherent unfragmented firmware landscape. Right now every vendor maintains their own fork of the one or other Open Source firmware. Based on my experience these forks rarely see bug fixes, improvements or features merged from the upstream versions of those firmwares. The result is a horribly fragmented environment, making it incredibly difficult to write software that works reliably with printers out there in the wild. A bit more working together and being more conscious about the consequences of fiddling around with things would go a long way here.

Michael Petch: Do you have any other RepRap thoughts you’d like to share?

Gina Häußge: I’m excited to see what the next decade will bring!

The history of RepRap

You learn more about the early days of RepRap 3D printing in the articles already published to mark the 10th Anniversary of RepRap.

We still have much more to come so make sure you subscribe to the 3D Printing Industry newsletter and follow us on social media.

You can support OctoPrint here.

Want to work in additive manufacturing or looking for a 3D printing job? Sign up for our free jobs service now.