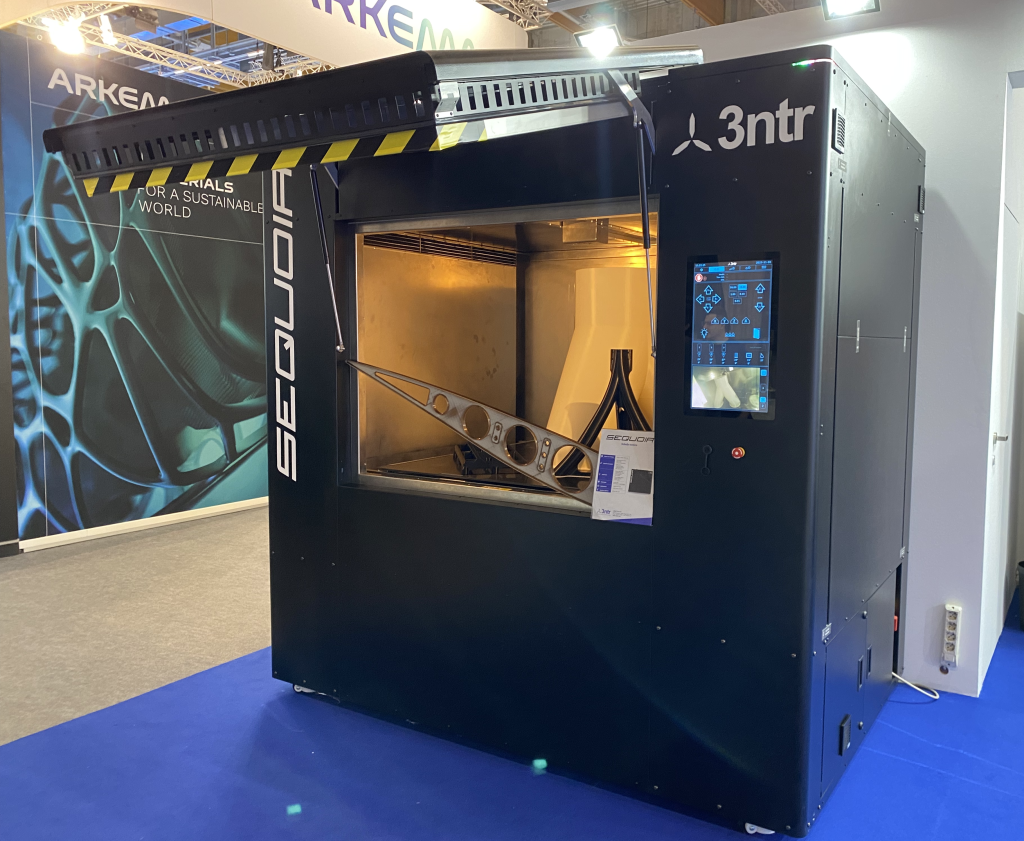

During an interview at Formnext 2023, Davide Ardizzoia, CEO of Italian 3D printer manufacturer 3ntr, discussed the company’s large-format Sequoia 3D printer.

Before the Frankfurt-based trade show, Ardizzoia stated that he would only conduct interviews inside the Sequoia’s build chamber, and this was no joke. Able to easily accommodate two people, the Sequoia features a substantial 1200 x 1100 x 900 mm build volume and a 130℃ heated chamber.

First announced at Mecspe 2022, the Sequoia is 3ntr’s first V5 series 3D printer. This offering adds to the company’s existing portfolio of A4, A2, and Spectral 30 FDM 3D printers.

“Why did we make Sequoia? Why not?,” stated Ardizzoia. “So many people need a heated build chamber and precision when manufacturing large parts. They can’t put parts together, they need to 3D print them in one shot. So many people were looking for that, we had to do it.”

From textiles to 3D printing

Based in Oleggio, a province in northern Italy, 3ntr is a division of swimwear and lingerie company Jdeal-Form. Founded over 60 years ago, Ardizzoia explained how demands in the corsetry industry led to the adoption of additive manufacturing.

“We started using additive manufacturing to make our machinery,” explained Ardizzoia. “Within our machinery, there are several parts made with additive manufacturing that can’t be made in any other way.”

Ultimately, persistent delays from the company’s additive manufacturing suppliers led the company to produce its own 3D printer. “We took six months to make the first one,” commented Ardizzoia. “I started wondering, why don’t we sell it? Because customers, friends, suppliers saw it and they started asking if they could have one.”

As such, the company developed its first 3ntr 3D printer, which debuted at the 2013 Maker Faire in Rome. “We started selling online, then we moved to a network of resellers, and now here we are. We are a 3D printing company and we just make 3D printers,” stated Ardizzoia.

3ntr has since built up a sizable portfolio of FDM 3D printers such as the Sequoia, Spectral 30, A2v4, A4v4, and A4SP Smart Power. The company also offers the STORM and VENTO filament dying units.

3ntr’s 3D printers cater to a wide range of industrial applications. “It is quicker for me to tell you who are not our customers – jewelry and dental,” stated Ardizzoia. “Any other company in the world can be our customer.”

Ardizzoia pointed to automotive, aerospace, motorbike, helmet, luxury footwear, software, and medical companies as leveraging 3ntr technology. For instance, one Swiss medical startup has used 3ntr technology to optimize radiotherapy treatment. Here, the company 3D printed a personalized mold to hold the patient in place under the radiotherapy device.

“This decreases the time it takes to place the customer under the irradiation device,” explained Ardizzoia. “This means that you can speed up the usage of the device. Usually, you can treat three patients an hour, but with this approach, you can treat four or five patients. It means that you’re saving more lives at the same cost, so that’s great news for everyone.”

The Sequoia large-format 3D printer

According to Ardizzoia 3ntr decided to produce a large format FDM 3D printer with a heated build chamber due to customer demand. Customers reportedly wanted to 3D print large-format, high-precision parts as a single piece, without 3D printing multiple parts to be stuck together afterwards.

Thanks to its 130℃ heated build chamber, the Sequoia offers compatibility with a range of high-performance polymers such as TPU and ABS. What’s more, as with other 3ntr 3D printers, the Sequoia includes three nozzles, allowing for multi-material 3D printing. Ardizzoia explained that this allows for a broad range of properties, with customers 3D printing parts with two kinds of rubber, soft and hard, in a single part.

Ardizzoia highlighted one notable application of the Sequoia as being within the oil and gas industry. “It is a big surprise to us because we didn’t know that oil and gas was asking for large, round parts of super polymers.” Moreover, the Sequoia is said to have also been utilized in cruise ships, shipbuilding, and autonomous vehicles.

“The capabilities are growing as we speak, and during Formnext we have the chance to sell new machinery to new customers we didn’t even know were looking for these kinds of machines,” explained Ardizzoia. “So it is quite exciting for us.”

Indeed, since its launch last year, the Sequoia has been well received. Ardizzoia highlighted that 3ntr successfully planted three new Sequoia 3D printers at Formnext alone. “Overall we have probably sold the first batch of Sequoia’s, so we are speaking about several machines,” explained Ardizzoia.

Looking to the future, Ardizzoia stated that the 3ntr is now planning to develop new products and technologies. As such, the company is looking to grow its employer base. “There are several new topics we want to cover. Along with the good guys we have already, we are looking for new people,” stated Ardizzoia. “We are adding new mechanical engineers and also programmers because deep learning is a hot topic.”

Technical specifications and pricing

Prospective customers can request sales and product information via the 3ntr website here.

| 3D Printer Technology | Fused Deposition Modeling (FDM) |

| Mechanical Features | Brushless motorization, beltless, micrometric precision |

| Calibration | Z calibration, plate leveling, extruder leveling: all automatic |

| Maximum Temperature | 130℃ heated chamber, fast heating and low consumption.200℃ heated build plate, removable tray and reusable |

| Drying | 6 Vento drying units |

| User Interface | 19.5” touch-screen display |

| Storage | 500GB |

| Electrical Requirements | 380Vac, 3 phase, 32A |

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the 3ntr Sequoia large-format 3D printer at Formnext 2023. Photo by 3D Printing Industry.