Formnext 2023 saw a plethora of software companies showcasing 3D printing software.

One such company was Interspectral which offers AM Explorer, a process monitoring and quality assurance software for metal additive manufacturing.

3D Printing Industry spoke with Interspectral CEO Isabelle Hachette at Formnext 2023 to learn more about this software, and how the company plans to develop its offering in the future.

Launched to market back in 2020, AM Explorer is a visualization software that allows users to simulate, monitor, and analyze data from metal additive manufacturing processes.

Whilst AM Explorer offers broad compatibility within the metal 3D printing space, it is optimized for laser powder bed fusion (LPBF) and direct energy deposition (DED) technology.

“We provide software that fulfills quality assurance for metal additive manufacturing and industry 4.0,” explained Hachette. “We are experts in handling complex data, and bringing it all together into a comprehensible and understandable digital twin.”

During Formnext, the Sweden-based company announced a new integration with the EOSCONNECT Core platform. This integration will reportedly enhance the process monitoring capabilities of EOS customers within aerospace, space, defense, and automotive applications.

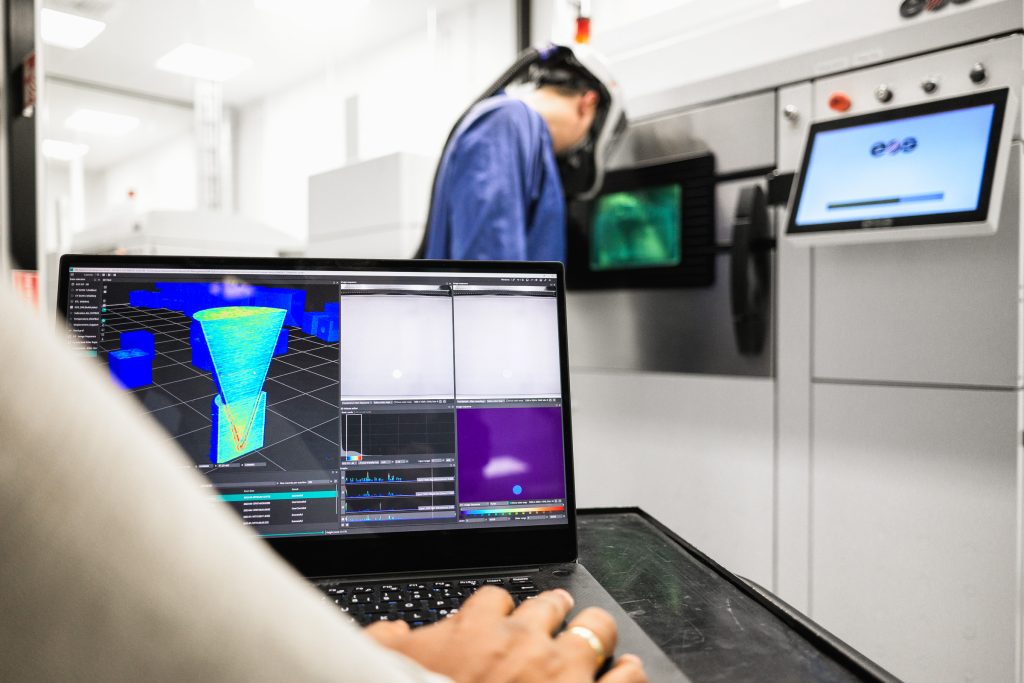

Interspectral’s AM Explorer software

The development of AM Explorer first started back in 2017 as part of a collaboration between Interspectral and industrial manufacturing firm Siemens Energy. This partnership saw the two companies develop a 3D visualization tool to optimize the production and design of 3D printed components to repair industrial turbines. AM Explorer was launched two years later and received a full release to market in 2020.

Since its launch, Hachette stated that AM Explorer has been very well received. “I think we are seen as an innovative player because we came up with the right knowledge that was lacking in the industry.”

AM Explorer enables the creation of multi-channel digital twins, allowing users to duplicate and digitally simulate their additive manufacturing processes in real-time. Within AM Explorer, digital twins can be combined with virtual reality (VR) and augmented reality (AR) to allow for a more intuitive interaction with the process simulation process.

According to Hachette, “You can have a build plate, and you can also have a digital twin of the build plate, and then you can interact with that. You can manufacture not only the physical component but also the digital twin.” For instance, Hachette pointed to a use case whereby a digital twin was generated during the development of an industrial turbine. The digital twin and VR capabilities of AM Explorer allowed engineers and designers to inspect the turbine on a mobile phone through the cloud. Moreover, the AR capabilities allow digital twins to be viewed and manipulated in real-world environments.

Optimizing the efficiency of metal additive manufacturing

At the core of Interspectral’s software is increasing the efficiency and ease at which users can monitor and analyze the metal additive manufacturing process.

Indeed, Hachette highlighted AM Explorer as being especially well suited to serial production applications.

“If you have a high level build job with something like 135 components and you detect an error, it’s not likely that the whole build job has faults in it, it’s maybe only nine components that are faulty” explained Hachette. “AM Explorer can show exactly which components have errors. Instead of throwing the whole print job, you can throw away only the erroneous components.”

As such, Hachette outlined significant time and cost savings offered by AM Explorer for LPBF processes. “It depends on the use case, but we have seen that you can save €500,000 per ten machines each year.”

What’s more, Hachette outlined that this software is vendor agnostic, meaning that customers “only need to use one software to qualify and assure their components on multiple 3D printers.” This makes AM Explorer especially well suited to industrial-scale additive manufacturing applications where multiple metal 3D printers are used in tandem, saving time and money in the process.

Ultimately, Hachette sees developments in 3D printing software as playing an increasingly important role within additive manufacturing, especially with regard to making advancements in hardware.

“Additive manufacturing is a developing industry, and there’s been a lot of focus in hardware, and doing the hardware right, which is very complicated,” Hachette explained. “Now comes to the next stage, where we need to have really good software today to make sure that the hardware is right.”

Looking to the future, Interspectral is working to increase the integration of artificial intelligence (AI) into its software offering next year as part of a strategic initiative. “The next step in the roadmap is an AI intelligent decision support system that we are working on now quite intensively with R&D,” added Hachette.

Integration with EOS

During Formnext, Interspectral announced the launch of an EOSCONNECT Core integration module in AM Explorer. This module will provide EOS customers with direct access to comprehensive process monitoring data from EOS 3D printers within AM Explorer.

“When conversing with the market, we recognized that many end users were grappling with laborious manual quality inspection processes. With this new feature, we’re addressing this challenge head-on, breaking down data silos for EOS users,” commented Hachette in a press release.

“They can now seamlessly access data from their printers and analyze it with powerful interactive 3D visualization, combining it with information from simulations and post-build analyses.”

Interspectral’s software has already been successfully deployed globally to EOS customers, including several “major service providers,” R&D labs, and powder suppliers.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Interspectral software in use with an EOS 3D printer. Photo by 3D Printing Industry.