Swedish software company Interspectral has announced the release of its visualization software package, AM Explorer, to the broader metal additive manufacturing market.

AM Explorer was initially developed for Siemens Energy, enabling the firm to explore, monitor, and analyze data from its metal 3D printing processes. Now, Interspectral is rolling out the software to others in the market with the hope of positively impacting metal additive manufacturing costs, quality, and timelines.

“The first step in enabling far-reaching intricate designs and further pushing the possibilities of additive manufacturing is to see and understand what really has been printed,” said Andreas Graichen, group manager of Siemens’ AM Center of Competence in Finspång, Sweden.

AM Explorer visualization software

Interspectral first collaborated with Siemens in 2017, when the two firms began a project to develop a 3D visualization tool that could optimize the production and design of 3D printed components to repair industrial turbines. Two years later, AM Explorer was launched – designed to import and visualize large amounts of heterogeneous data from the metal additive manufacturing process in one environment.

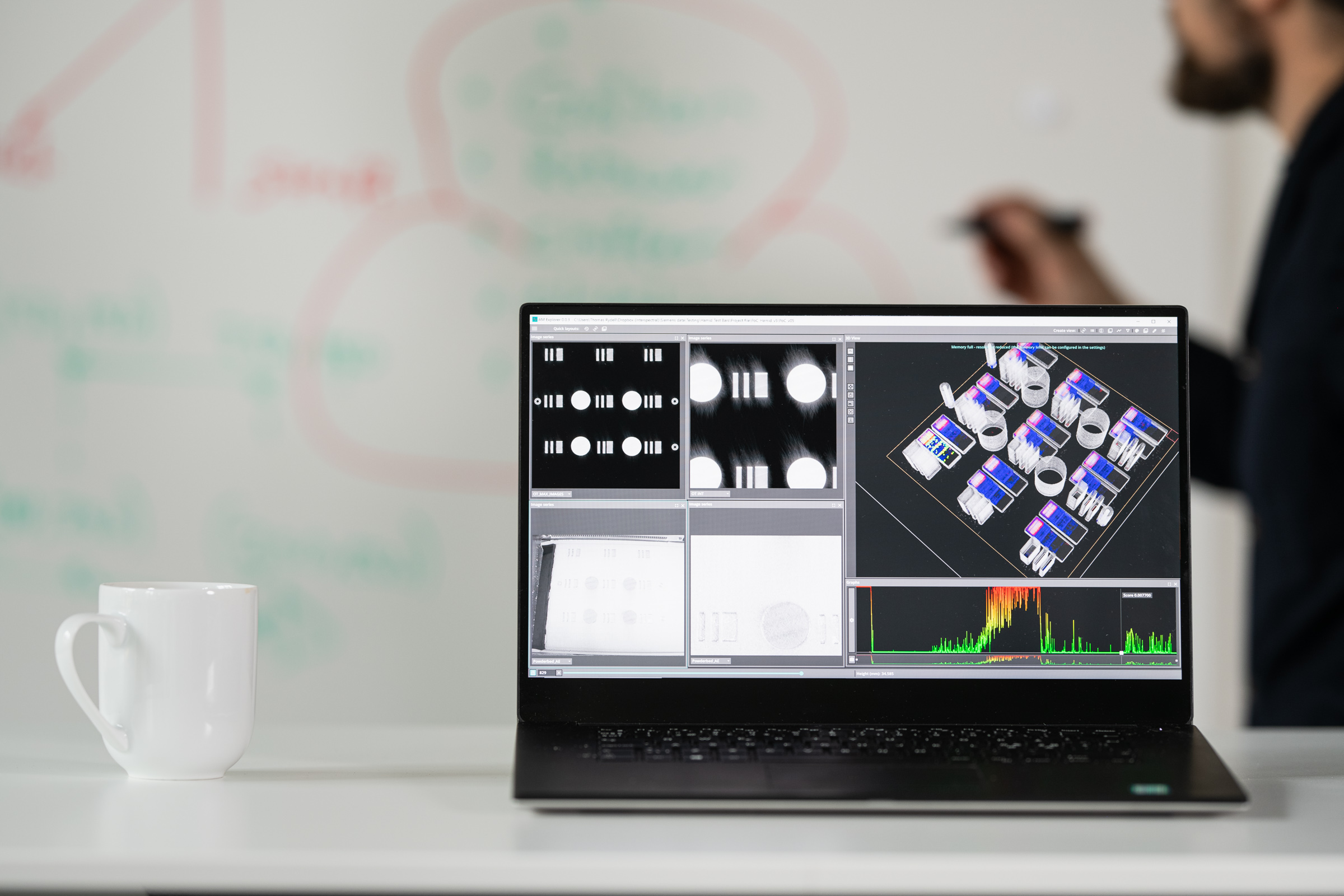

The software enables users to analyze design files, simulation data, machine monitoring data, and post-build metrology data from a process and aids them in exploring and understanding it. Being machine and data agnostic, AM Explorer is able to be easily integrated into existing systems to allow almost any organization working with metal 3D printing access to the software.

“With AM Explorer users can explore data from their own process regardless of their infrastructure,” explained Thomas Rydell, Interspectral co-founder. “In the same visual environment they can explore data ranging from design files, simulations, machine monitoring data, and powder bed images to more complex data such as optical tomography and melt pool data, it’s even possible to explore CT scan data.”

A year and a half on from its launch, AM Explorer will now be released to the wider metal additive manufacturing market in a bid to accelerate the industrialization of metal 3D printing technology. The software package will continue to be developed in dialogue with Siemens and other early adopters of AM Explorer.

“We are very pleased with the launch of AM Explorer to the market as we believe that it will bring value to the industry,” Rydell continued. “We are looking forward to partnering up with additional innovative companies so we can learn even more about issues in the industry and further develop AM Explorer to overcome these challenges.”

monitoring data and post-build metrology data from the metal additive manufacturing process in 3D. Image via Interspectral.

Data and metal additive manufacturing

Automating the monitoring of metal 3D printing and analyzing the data collected during the production process are important in improving quality, saving time, and reducing the costs of metal 3D printing methods.

At Formnext 2019, Altair’s Solidthinking division launched Inspire Print3D, a simulation tool allowing designers to use a thermo-mechanical approach to generate designs then modify and evaluate by adjusting process variables. The software also offers printing analysis through an embedded thermo-mechanical solver which simulates the entire printing process from building and cooling to cutting and springback. Also at the event, GE Additive unveiled a new suite of machine health data analytics known as the Arcam EBM Build Performance Analyzer.

Elsewhere, metal additive manufacturing firm VELO3D has made enhancements to its Flow print preparation software, while Renishaw and Identify3D showcased software at RAPID + TCT designed to secure data in the metal additive manufacturing processes. The software integrates intellectual property protection, manufacturing repeatability, and traceability with the aim of deterring and countering security threats.

Most recently, researchers from Oak Ridge National Laboratory (ORNL) developed artificial intelligence software, nicknamed Peregrine, able to monitor the metal 3D printing process in real-time. The team believes their algorithm could potentially be utilized as a quality control method for self-correcting machines.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows AM Explorer is machine and data agnostic and is easily plugged into existing systems. Image via Interspectral.