3D printing materials supplier Infinite Material Solutions has launched a new soluble support filament designed to be co-extruded alongside high-temperature polymers.

Dubbed AquaSys 180, the material features excellent temperature stability and can withstand atmospheric temperatures of up to 180°C. As such, it is suitable for the printing conditions required to extrude high-performance thermoplastics such as PEEK, PEKK, PEI, and PPSU, which often require nozzle temperatures above 300°C.

Dr. Jeff Cernohous, the founder of Infinite Material Solutions, explains: “We are extremely excited to launch our AquaSys 180 product. AquaSys 180 can be printed at chamber temperatures up to 180°C and has been engineered to function with high-temperature engineering thermoplastics such as the ones in the PEEK family, providing unprecedented design freedom to our customers as a result. I am extremely proud of my team for their efforts to create this disruptive product.”

High-performance polymers in additive manufacturing

The thing that makes PEEK, PEKK, and many other high-temperature polymers great for engineering applications is their jack-of-all-trades high-performance nature. The materials display excellent corrosion resistances, all while being relatively strong. This powerful combination makes them a fantastic choice for chemical-contacting parts in industries such as energy and aerospace.

Unfortunately, the FFF printing of these materials tends to come with some challenges. Provided you have a 3D printer that can maintain the nozzle and chamber temperatures necessary for a successful build, you may be limited in your choice of support materials, seeing as PEEK itself is not known for being cost-efficient.

Many of the options available to manufacturers are either highly proprietary, call for manual removal, or require an abundance of harmful solvents to dissolve them. PVA, which is usually the go-to water-soluble support material, simply doesn’t have the correct thermal properties in this case.

What makes AquaSys 180 special?

With a seemingly gaping hole in the market, there is indeed a niche for water-soluble support materials to complement high-performance 3D printed parts. Using a water-soluble filament not only reduces the cost and time of downstream post-processing but also grants a greater degree of design freedom, as you’re not forced to cater to a highly manual support removal process right at the design phase.

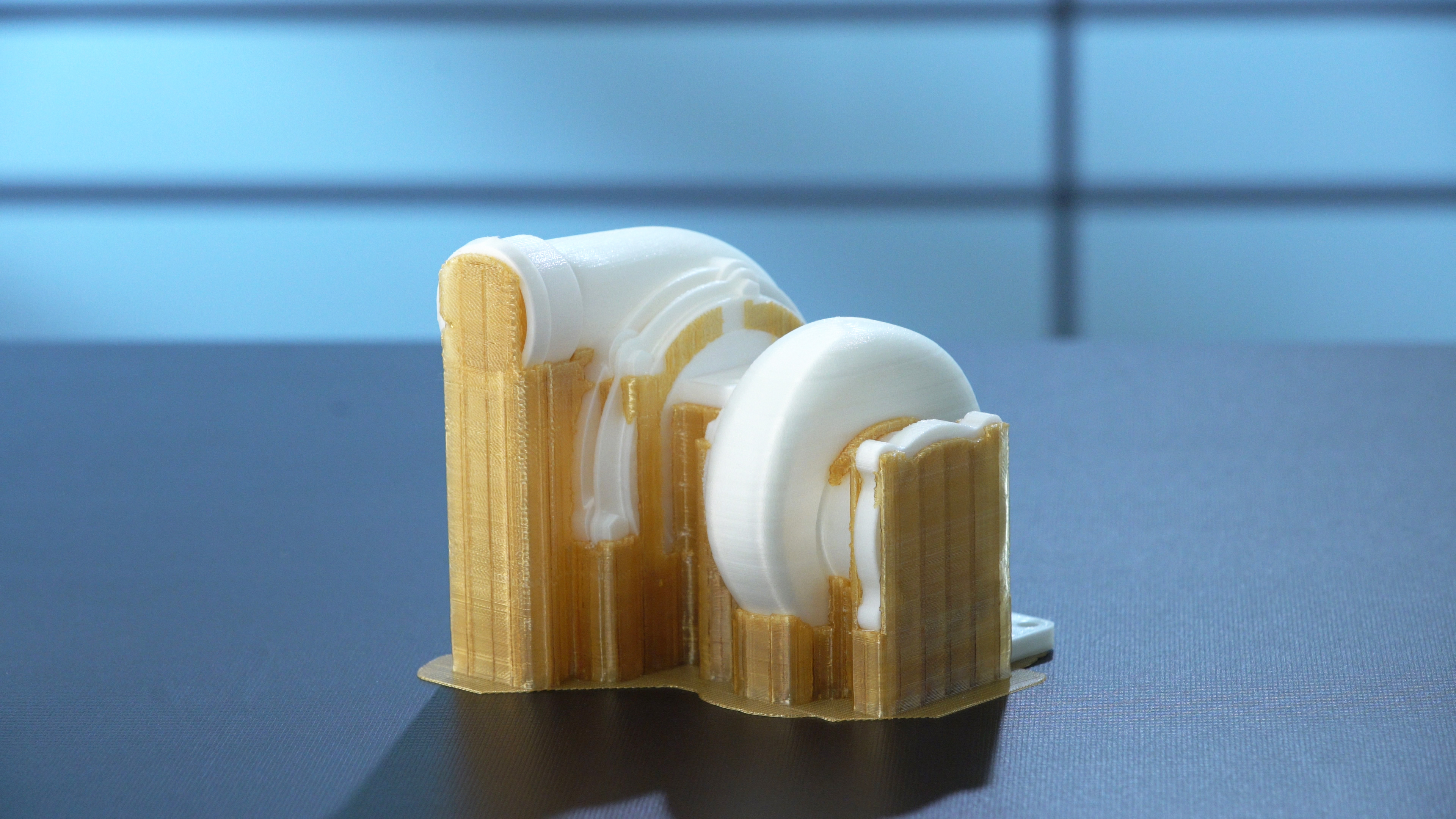

With an intent to fill the niche, AquaSys 180 is completely soluble in warm tap water and features excellent compatibility and adhesion to a wide range of build materials. The formulation, which comprises a polymer base, a compatible disaccharide (Trehalose), and a reinforcing additive, is patent protected. The filament is also reportedly non-toxic and non-carcinogenic (although this doesn’t make it safe for ingestion).

Novel filaments are rife in the 3D printing industry, with materials vendor Reflow having recently launched a new eco-friendly range of ‘Seaglass’ translucent materials for the FFF process. The company’s sustainable line of six rPETG materials is made from locally-sourced plastic and visually inspired by the environment. Through its new range, Reflow aims to do its part in limiting the harmful effects of plastic pollution worldwide.

Elsewhere, 3D printer manufacturer RIZE recently debuted its RIZIUM Glass Fiber filament for use with its 3D printers. The highly-durable composite material claims to have high dimensional stability and high stiffness, and is primarily intended for large-part production.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an industrial 3D printed part supported with AquaSys 180. Photo via Infinite Material Solutions.