In-Vision, an Austria-based developer of high-precision optical systems, has announced the launch of its most powerful 3D printing light engine to date.

Backed by two years of research and development, HELIOS is a UV light projector designed specifically for resin-based DLP systems. The engine aims to achieve the highest illumination intensity in the market space, enabling faster cure times and compatibility with a greater number of photopolymer resins.

Christof Hieger, CTO of In-Vision, states: “There has always been a high demand for more light intensity among our customers (including some of the world’s leading 3D printer manufacturers). However, we could not find an off-the shelf light source that could fulfil this need. We knew we had a team who was able to come up with a great product, so we started our own development.”

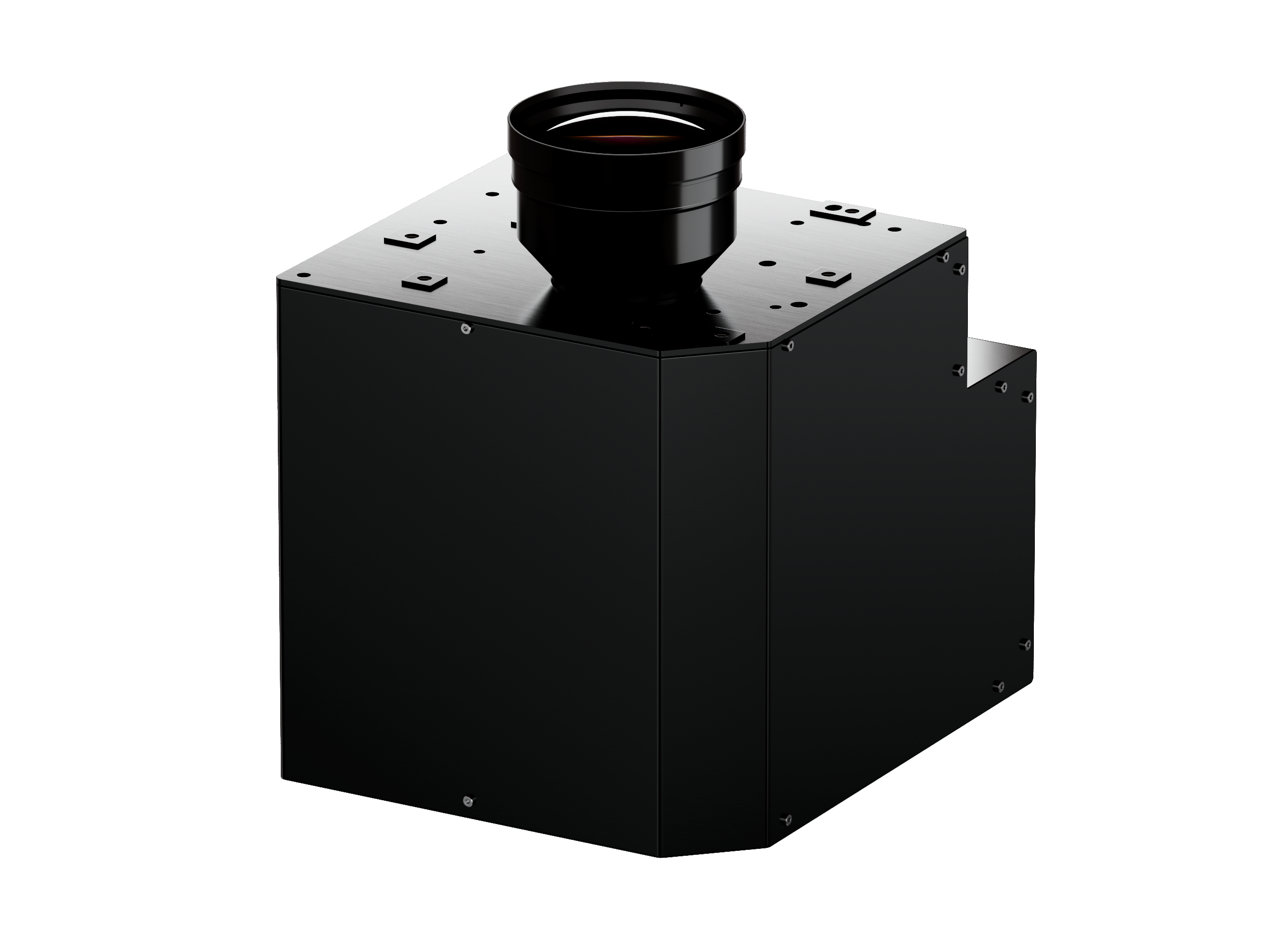

The HELIOS light engine

Based on the company’s own proprietary light source, the HELIOS engine is capable of achieving up to 60W of illumination intensity, which is reportedly around double the industry standard. As a result, more than 12W of power is delivered on the image plane. In-Vision has also stated that all of the device’s optical elements and their respective coatings have been optimized to provide a higher level of light uniformity and contrast ratios, when compared to its competitors.

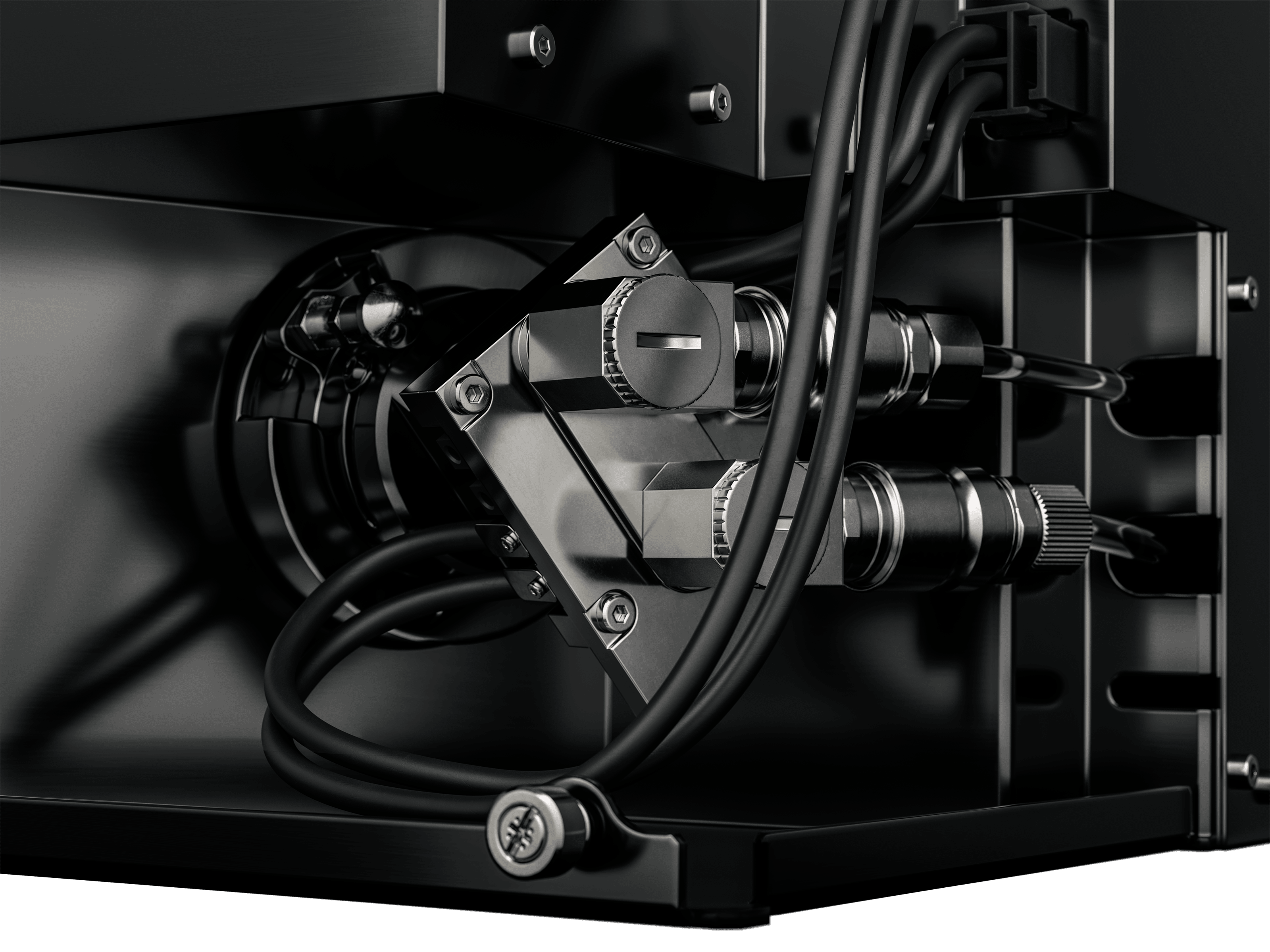

Referring to the user-centric focus of the engine, Gerold Aschinger, Head of the HELIOS development team, adds, “It has never been easier to operate and maintain a DLP light engine. The entire projector follows a modular design: it is fully built in sub-assemblies for the highest level of accessibility and the LED module can be easily exchanged by the customer.”

The push towards faster production

HELIOS is ultimately intended to offer a more cost-effective method of rapid production, while enabling a greater degree of choice between resin materials and qualifying 3D printing for serial application applications. The light engine is available in a number of custom pixel resolutions and UV wavelengths, such as 385nm, 406nm, and 460nm. The company has already received its first set of orders from customers in the US and Asia, with mass production set to commence sometime this month.

With similar speed-based goals in mind, two-photon polymerization 3D printing specialist UpNano recently used a high-power laser to speed up the printing of nanoscale parts by 12 orders of magnitude on its NanoOne system. The laser was aided by a new optimized optical pathway and smart laser scanning algorithms.

Elsewhere, in Sweden, binder jetting 3D printer manufacturer Digital Metal has also previously upgraded the production volume of its proprietary systems, albeit through a software update. Specifically, the upgrade tripled the print speed of the company’s DM P2500 3D printer.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the HELIOS light engine. Photo via In-Vision.