Dr. Steve Lee, at the Australian National University (ANU) Research School of Engineering, along with Dr. Tri Phan, of Sydney’s Garvan Institute of Medical Research, have developed a novel method for fabricating high-powered lenses that can turn your smartphone into a high-resolution microscope. How did they manage to do it? By relying on the structural integrity of Universe (as Bucky would say)!

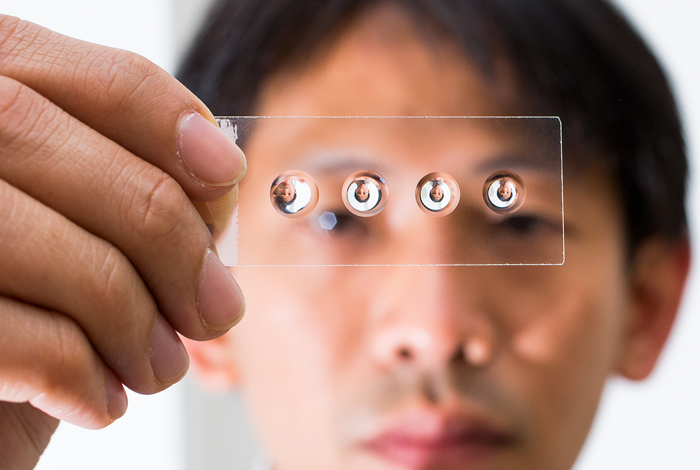

To produce the lenses, the researchers squeeze liquid droplets of silicon gel onto a microscope cover slip and flip the slip over, allowing gravity to form a naturally parabolic shape. Lee explains, “We put a droplet of polymer onto a microscope cover slip and then invert it. Then we let gravity do the work, to pull it into the perfect curvature. By successively adding small amounts of fluid to the droplet, we discovered that we can reach a magnifying power of up to 160 times with an imaging resolution of four micrometers.” Lee discovered the lens fabrication method quite by accident, saying, “I nearly threw them away. I happened to mention them to my colleague Tri Phan, and he got very excited. So then I decided to try to find the optimum shape, to see how far I could go. When I saw the first images of yeast cells I was like, ‘Wow!’”

Lee’s lenses don’t require the same grinding and processing technique as traditional glass lenses. The droplets, with their 160x magnification power and 4 micron image resolution, are formed from polydimethylsiloxane (PDMS), the same material used for contact lenses, which means that they are scratch resistant and won’t break. Moreover, each lens costs less than a cent to make, so Dr. Lee says, “It would be perfect for the third world. All you need is a fine tipped tool, a cover slip, some polymer and an oven.”

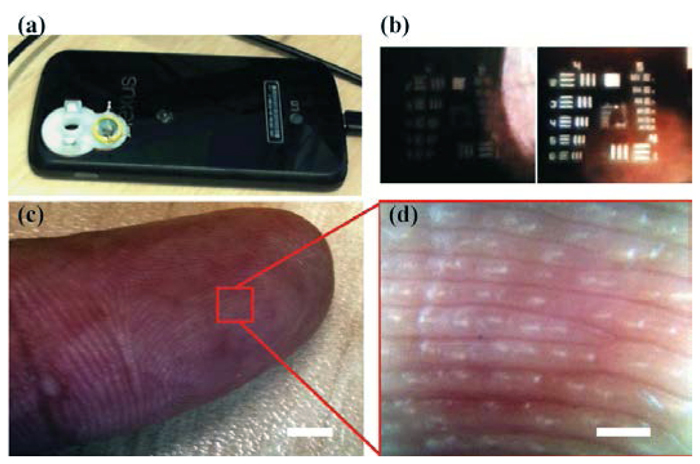

To test out the applicability of their lenses Dr. Lee and his team worked with Dr. Phan to create a 3D-printed frame to hold the lens, some LED lights, and a coin battery. When attached to a Nexus 4 smartphone, the device becomes a de facto microscope. The potential uses for the smartphone microscope are endless when used with the appropriate apps. For instance, doctors in remote areas might be able to diagnose illnesses on the fly, with Dr. Phan saying, “This is a whole new era of miniaturisation and portability – image analysis software could instantly transform most smartphones into sophisticated mobile laboratories. I am most able to see the potential for this device in the practice of medicine, although I am sure specialists in other fields will immediately see its value for them.”

For that reason, a German group has contacted the researchers about creating disposable lenses for tele-dermatology. Lee adds, however, that the uses aren’t limited strictly to the field of medicine, “There are also possibilities for farmers. They can photograph fungus or insects on their crops, upload the pictures to the internet where a specialist can identify if they are a problem or not.”

If you want to try making your own, Lee and Phan’s method for fabricating the lenses, as well as how they compare to those of standard microscopes, is documented in a study titled “Fabricating low cost and high performance elastomer lenses using hanging droplets“, published in the most recent issue of Biomedical Optics Express. If you’re not in the mood for skimming scientific articles, Dr. Lee describes the lenses in terms that we can all understand in the video below:

Source: Engineering.com