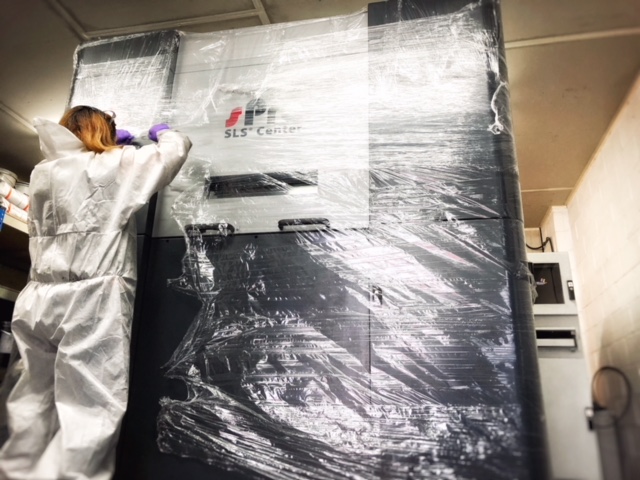

UK 3D printer materials company and service bureau Graphite Additive Manufacturing has invested in a further selective laser sintering (SLS) 3D printer as part of a new “EXPRESS” fast-track service for its customers.

The Aylesbury-based company, which offers materials, rapid tooling, prototyping and consultancy services, purchased the 3D Systems Vanguard 3D printer to “help cut growing lead times” when SLS 3D printing.

Graphite Additive Manufacturing’s Marketing manager Jonathan Warbrick spoke to 3D Printing Industry about the company’s decision to invest in a Vanguard, and how it will rapidly manufacture end-use parts for the company’s customers across a range of industries.

The need for a new SLS 3D printer

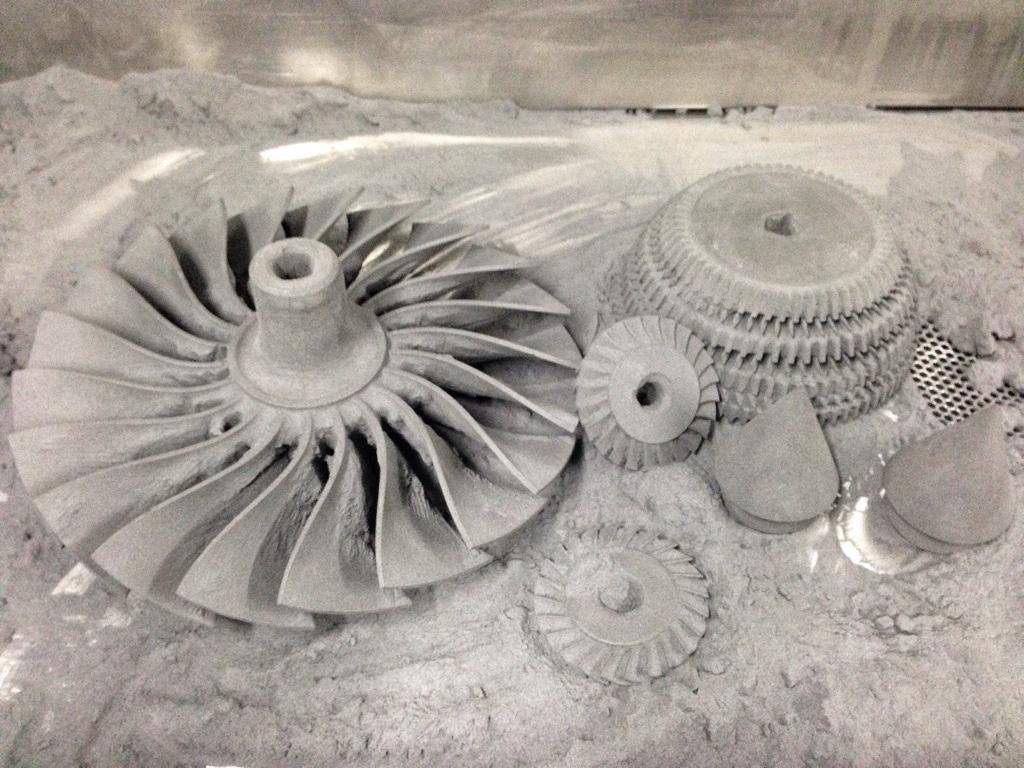

Graphite Additive Manufacturing currently develops its own carbon fiber and graphite SLS 3D printer materials, to use them for end-use parts.

The company states that it has been receiving increasing demand for SLS 3D printed parts, and it recently produced over 3000 parts in one SLS build. However, prior to purchasing the Vanguard at the end of November 2017, lead times were too long.

“When you have F1 companies requiring parts on demand, and you quote them a lead time of seven to ten days, unsurprisingly you end up losing business,” said Warbrick in a phonecall today. “We are very pleased with the internal build, accuracy and surface finish Vanguard, and it is considerably faster than our other SLS 3D printers.

With a build volume of 370 x 320 x 445mm, the Vanguard 3D printer is helping the tam slash lead times in half. The bureau is now capable of manufacturing multiple graphite and carbon parts in a week, with production times for some parts now under 24 hours.

A range of end-use applications

Graphite AM has previously 3D printed radio-controlled cars using its carbon fiber material, and has increasingly been producing parts for professional UAV drone technology.

The new Vanguard 3D printer will be running graphite and carbon reinforced nylons, producing lightweight and durable performance parts.

“Customers have been especially pleased with our graphite reinforced Nylons, because of its high impact resistance,” Warbrick explained. “We are really excited about the future potential of SLS.”

While the earliest users of the technology were F1 companies, Graphite AM is now producing parts for general automotive, UAV, and aerospace applications, with, according to the company, further projects in these industries on the way.

Nominations for the second annual 3D Printing Industry Awards are now open. Make your selections now.

For more stories about UK additive manufacturing companies, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows ReHook 3D printed graphite parts from Graphite AM. Photo via Graphite AM.