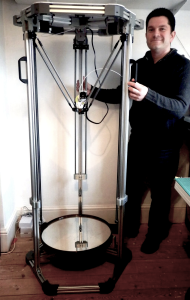

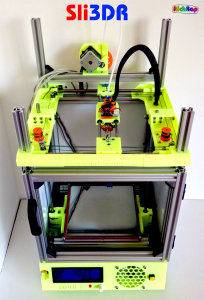

Once upon a time, there were three bears that lived in a house (for some reason) and a little blonde girl snuck into the house (for some reason) and decided to 3D print some Yoda heads (for good reason). Sitting in the bears’ makerspace, there were three different RepRap 3D printers designed by Richard “RichRap” Horne, mainstay of the RepRap community. In an effort to ensure that delta-style 3D printers continue to use 3D printed parts, in the self-replicating tradition of RepRap, Rich designed a 3D printer called the 3DR. The quiet, elegant deltabot had a number of 3D printed parts and has been, for Rich and others, quite the workhorse. The RepRapper, however, wanted to expand his design in size, leading to the construction of the 3DRnano and the 3DRmega.

Rich tells me that the reasons behind creating these two very different 3D printers were to explore the possibilities of 3D printing, saying:

One of the main reasons I made a both a small, battery powered portable nano and also a large mega (could be lots bigger) design, was to explore both ends of the 3D printing spectrum and push some boundaries of what’s available. It’s also interesting that with regards to cost, making a nano, mega or even the standard 3DR are all within a few hundred dollars of the cost of parts. You don’t need to spend $8k or more just to get a large 3D Printer and having a portable, battery powered one should also not cost the earth, in every sense.

When I asked Rich for a comment on the project, saying that many people will want to know how/when they’ll be able to get their hands on one of these designs, Rich gave me a reply that was too good not to quote in full here:

It’s always the number one question I get asked – “Where can I buy one and will you do a kit for me?” That now gets asked more than ‘where are the files’, that used to be the first call.

3D printer kits are tricky, to do them well you have to stop, focus and aim to build a business around them, that does not leave very much time for development or new machines or other interesting 3D Printing projects. It also means things on the design have to freeze at least for some time to enable kits or machines to be made.

I launched my RepRap 3DR printer into the Open Source community this time last year at the mini maker-faire in London, with lots of documentation and guides on how to build etc.

Two great things happened, the first was a lot of people wanting kits, parts and generally to own one as soon as possible, during the summer I had hundreds of inquiries for 3DR, by the time TCT approached my blog was getting over 1M page views. That’s a lot of demand. Some people have now built businesses around my 3DR design and other projects I have released in the past, that’s great to see.

The more interesting aspect was that lots and lots of people in the open source community built my 3DR themselves, exactly as I intended, many adapted, modified and designed all sorts of variants of 3DR, some of which I have posted on my blog about, but many more keep on popping up. This makes me very happy to see. It’s not making me any money, but it is keeping the idea of a print it yourself ‘RepRap’ 3D printer going strong.

In this industry I would not rule out anything, and it’s always exciting to see what feedback you get with a project, blog post or idea. I always hope that leads to collaborations and open innovation, that’s what I’m looking for.

I designed four completely different 3D printer designs in parallel over the last six months, I would certainly not recommend doing that, but it was driven by the fact that we have not even seen 1% of what 3D printing can do for users yet. Rather than keep on putting out the same box designs we need constant open innovation and reasons to change things to solve new and interesting problems for real people

My designs and development in 3D printing are open, and I always ask people to feedback to me what they like or dislike, also if people want printer kits or parts, then let me know, like I said, you can’t rule anything out.

I would like to be able to design and build custom 3D printers for anyone who needs one. I’m really interested in what people do with 3D printers and especially when boundaries are pushed with materials, size or interesting design requirements.

Rich will be attending the TCT show, this fall, as a representative of the RepRap community, so, if you’re attending, you may have an opportunity to see one or all of these machines in person. When I asked Rich about the importance of representing RepRap at TCT, he told me:

It’s no secret that I would like to see RepRap evolve into a foundation and continue to be a significant part of the 3D printing industry for years to come.

‘We’ will be back at TCT, hopefully with lots more to show and plenty of discussion. It would be great to get involved with the Inside 3DP, just let me know how we can get involved and I’ll make it happen.

It’s interesting that you ask why have a specific RepRap zone. I see an importance to have a representation of the maker community at shows like TCT and other 3D printing events. It’s not even about being commercial or not, just some focus for users that is not a single company but a group of people, developers and enthusiasts all interested in all aspects of 3D printing, rather than just what a single company sells or wants to specifically talk about.

3D Printing is still well in the growth phase, so spontaneous developments can happen from anywhere, it’s still a real shame that RepRap gets no funding or support in any way, it all runs on people’s time and their own personal funds.

I’m a bit jealous of my British colleagues who’ve gotten to meet this great fella in person. Maybe someday! As for Goldilocks, I’m not jealous one bit. She was, naturally, mauled by bears.