As 3DPI editor Rachel Park, a long-time commentator on the 3D printing industry, tells me, Gillette was one of the earliest consumer company’s to use 3D printing technology. Since the 90’s, the company has used additive manufacturing to prototype its shaving products. Unfortunately, 3D printing was incapable of prototyping functional razor cartridges, which would become deformed when exposed to hot water. For that reason, Gillette’s 3D printed prototype razor models could only be used for aesthetic development. A new patent filed> by the company, however, indicates that Gillette has found a solution to this problem.

According to the patent filing, Gillette will likely use digital light processing (DLP) to prototype the cartridges: “In a preferred embodiment, the housing is fabricated using an additive manufacturing that uses liquid ultra-violet curable photopolymer resin (UV-curable resin) and an ultra-violet laser to build parts a layer at a time. Ultra-violet light is applied to layers of UV-curable resin at a time to form a solid structure.” To increase the temperature resistance of its cartridges, the company may incorporate a “filler” material, such as aluminium oxide, crystalline silica, or a ceramic material:

The patent goes on to hint at the use of direct metal laser sintering for the creation of the razor’s metal inserts:

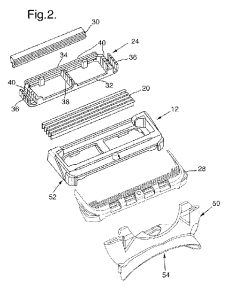

In a preferred embodiment, the metal insert is formed by direct metal laser sintering (DMLS), a form of rapid prototyping…Forming a metal insert by the above described process provides a time efficient way of preparing different inserts with varied angles, positioning of slots and overall size, without suffering a reduction in quality. Once the metal insert has been formed, blade assemblies are loaded into slots of the metal insert before the metal insert is placed in the housing.

Other parts of the Razor, including the handle, are then described as being produced via selective laser sintering:

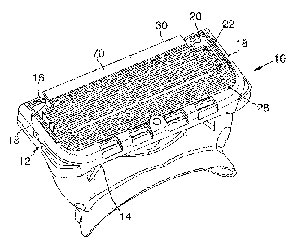

FIG. 2 further shows a connecting member affixed to an underside of the housing. The connecting member has a receiving section to which the end a of a razor handle (shown in FIG. 3) may be attached. The connecting member enables pivotal movement of the housing relative to a razor handle when, in use, the razor cartridge is pressed against an area of skin. The pivot axis A extends substantially parallel to the one or more blade assemblies. The connecting member may be formed using traditional molding techniques. In a preferred embodiment, the connecting member is formed by selective laser sintering (SLS), a form of rapid prototyping.

Before you go out telling everyone that Gillette plans to mass manufacture its razors with 3D printing, however, it’s unclear from the patent that this is their intent. If anything, it sounds as though 3D printing is being used, in this context, to help the company prototype their products more effectively: “rapid prototyping provides a quicker, more efficient means to experiment with different forms of a product before committing to the cost of making molds for mass production. In a field such as razor cartridges where small changes can make a significant difference to performance of a razor cartridge, having this flexibility in a functional razor cartridge is very valuable.”

There are phrases throughout the patent that do reveal a plan to use the razors for “repeated shaving”, which may be what has caused some other blogs to believe that mass additive manufacturing of razors is in the works. I’m afraid to make that conclusion, though. If you want to decipher the patent for yourself, let us know what you think. While doing so, look out for such pedantic descriptions of shaving science as pasted below:

The level of comfort obtained with any given wet shaving razor cartridge is influenced strongly by the shaving geometry, which is the relative positioning of the skin contacting components. Important parameters of the shaving geometry include the blade exposure which is the distance by which the tip of the blade edge projects above, or is retracted below, a plane which is tangential to the skin contacting parts next in front and next behind the blade edge, the blade tangent angle (also known as the blade shaving angle) which is the angle at which the plane of the blade is inclined to a plane which is tangential to the guard and the cap surfaces (the tangent plane), and the blade span which is the distance by which the blade edge is spaced from the skin contacting element immediately in front of the blade edge, as seen in a plane which is tangential to the blade edge and the skin contacting element in front of it.

Source: Google Patents