FFF 3D printer manufacturer German RepRap has added two new fiber-reinforced filaments to its material portfolio in partnership with American chemical company DuPont.

The filaments, Zytel 3D12G30FL BK309 and Zytel 3D10C20FL BK544, developed by DuPont Transportation & Advanced Polymers, were introduced at Formnext 2018. Both were developed in order to address industrial demands for stiffer and stronger materials. The filaments are said to be comparable to existing reinforced injection molding grades.

German RepRap and DowDuPont’s ongoing partnership

Founded in 1802, DuPont is a global chemical company that develops a varied selection of materials and products for industries such as food, medical and consumer. Publicly, the company made its entry into the 3D prining materials sphere in around 2015, through a partnership with talman3d. In 2017, DuPont merged with the Dow Chemical company leading to the establishment of DowDuPont, and making Dow Chemical a subsidiary.

German RepRap’s involvement with DowDuPont and its subsidiaries is a lasting partnership, which has previously seen the co-development of 3D printable Silicone Rubber material (LC-3335).

Zytel 3D printing filaments

German RepRap, headquartered in Munich, develops and produces 3D printers for customers around the world, including large industrial companies from automotive, medical and machinery industries.

The two new filaments from DuPont build upon the ultra-low shrinkage technology of existing Zytel PA polyamides, made applicable to the prototyping of automotive parts to electrical components.

The Zytel 3D10C20FL BK544 is a black polyamide reinforced with 20% carbon fiber, featuring a heat deflection level of >150°C, as well as resistance to most chemicals, solvents, fuels, automotive fluids and hydrolysis. Developed for lightweight components, the material is used by customers from various industries such as the automotive, electronics, and oil and gas industries.

The second filament, the Zytel 3D12G30FL BK309, is a 30% glass-reinforced polyamide, coming in black as well. This filament is heat-stabilized, with a heat distortion temperature of >166°C. Like the carbon fiber reinforced filament, it is resistant to most chemicals, solvents, fuels, automotive fluids and hydrolysis, with use in the same industries.

Alongside the new carbon fiber and fiberglass reinforced filaments, German RepRap also sells other filaments from DuPont, including more materials in the Zytel range, and the Hytrel range of filaments.

Want the latest 3D printing news? Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start this year? Visit 3D Printing Jobs to commence your career in additive manufacturing.

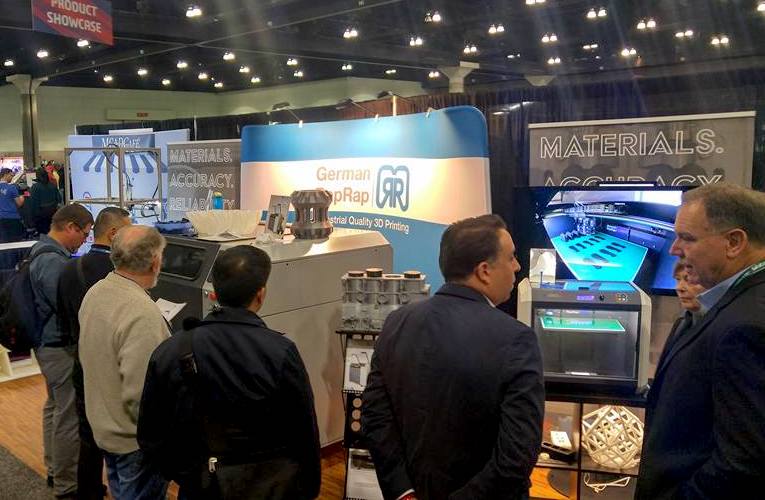

Featured image shows assorted Nylon 3D printed parts in DuPont Zytel.