German electronic 3D printing company Neotech AMT GmbH has announced it will engage in two new projects to advance additive manufacturing.

The first project, known as ‘Hyb-Man’, will bring together 11 partner groups from Germany and the Netherlands with the aim of developing hybrid manufacturing techniques. While the second project – AMPECS – will focus on the printing of ceramic substrates.

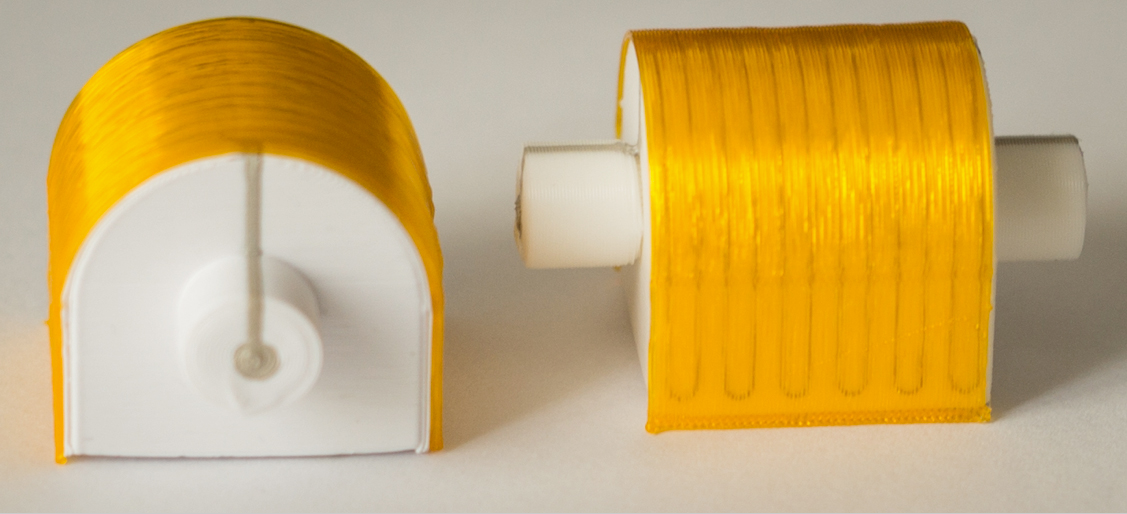

Video shows Neotech’s current capabilities.

Patented technology

Dr. Martin Hedges, Managing Director of Neotech explains the company has a patented 3D printing technology with “a proven industrial track record.” Speaking about the two new projects, he says

We have been working on combining 3D Printed Electronics with classical 3D Printing of mechanical structures and these new projects will accelerate the development. The ability to use fully Additive Manufacture to create complete 3D mechatronic systems enables many novel applications across diverse industries. The resultant process lines will address the needs for low volume agile manufacture within a single platform.

Hyb-Man

While sounding like a superhero, Hyb-Man is actually an EU PENTA project which means it is supported by the EU’s EUREKA innovation cluster. According to Neotech, the project will look to develop a new hybrid manufacturing process that uses 3D printed polymers as well as 3D printed electronics. Such a process chain will integrate quality monitoring and in-line testing processes. By combining 3D printed electronics with the printing of other materials, Neotech can provide full solutions for the creation of electronic devices. As the company explains,

The outcome of the project will be improved Additive Manufacturing processes, a hybrid manufacturing production cell and prototypes of integrated electrical products (LEDs, automotive adaptive sensors) made using the hybrid manufacturing cell.

Albuquerque-based company Optomec is currently developing its own electronics 3D printing technologies and recently created 3D printed turbine blade sensors for GE.

Ceramic printing

Neotech’s second project will involve a German-Spanish consortium and funding from the European Union’s Manunet Program. This program was set up to support “innovation-driven, close-to-market research and development projects in manufacturing.” Known as ‘AMPECS’, this project will primarily be concerned with the development of ceramic 3D printing as a compliment to its electronics 3D printing. The 3D printable ceramic materials are intended for extreme environment applications to harness the material’s advanced heat resistance properties.

With these two new projects, which the company refer to as mutually supportive, Neotech will look to expand its 3D printing technology and accelerate general industrial adoption. While elsewhere in the expanding 3D printed electronics industry, Optomec has been granted a $3 million research project and a Lithuanian company is developing an ultrasonic 3D printer for electronics production.

To stay updated with all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows a circuit board created using 3D printing technology. Image via Neotech.