The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Tell us now before this week’s deadline.

R&D firm GE Research, together with UC Berkeley and the University of South Alabama, has been awarded a two-year, $2 million project through the U.S. Department of Energy’s Office of Fossil Energy and Carbon Management.

As part of the ‘AIR2CO2’ research project, the partners will combine 3D printed heat exchanger technology with innovative sorbent materials to develop a system for effectively extracting CO2 from the atmosphere. In fact, the very same team is currently working on a similar approach to extract water from thin air as part of an ongoing Defense Advanced Research Projects Agency (DARPA) project to provide accessible clean water for troops on the front lines.

The Department of Energy’s award totals $1.5 million, with a cost share of $500,000 from GE and its University partners.

David Moore, Principal Investigator at GE Research, explains, “We’re combining GE’s extensive knowledge in materials, thermal management, and 3D printing technologies with UC Berkeley’s world-class expertise in sorbent materials development and the University of South Alabama’s absorption modeling and testing to design a novel system for removing carbon dioxide from the air.”

Breadth of expertise

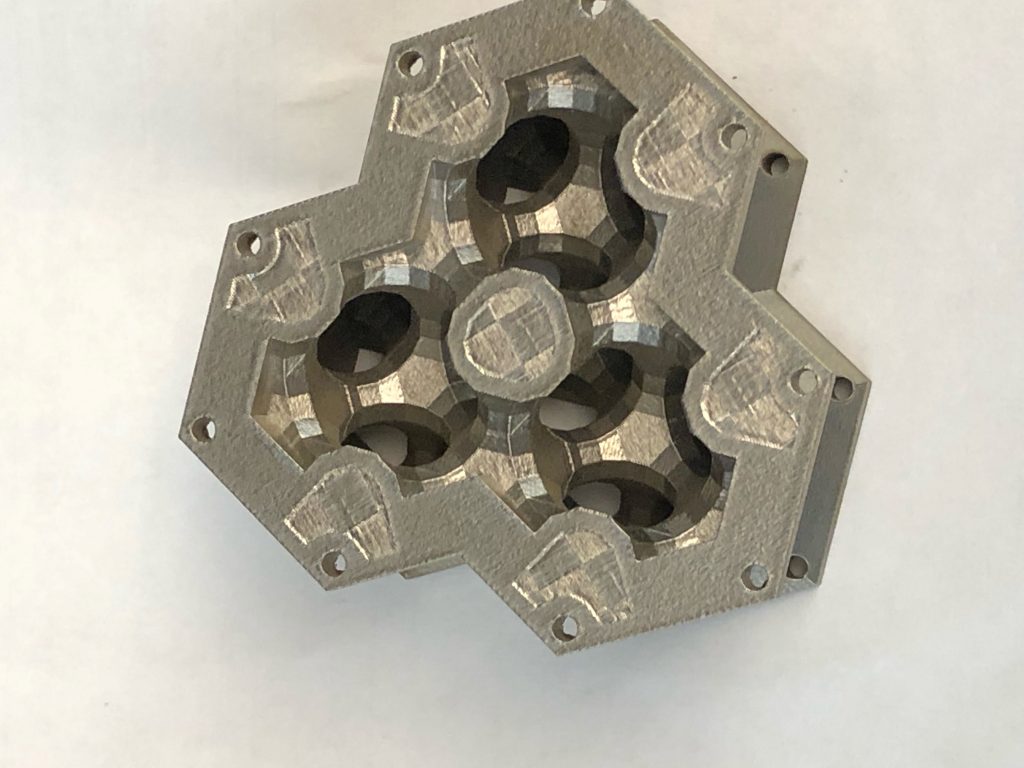

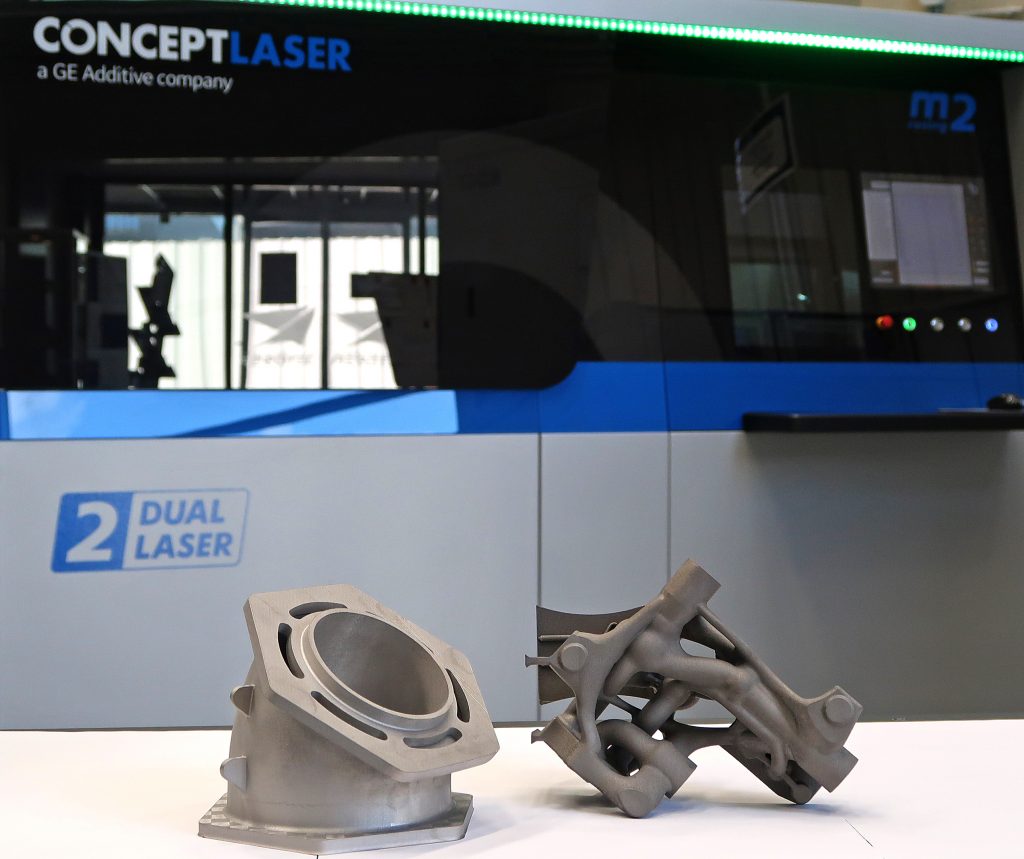

Owing to GE’s expertise in metal 3D printing via its GE Additive arm, the firm will serve as the project’s manufacturing partner. The company also brings decades of heat exchanger and thermal technology development experience from its gas turbine platforms for the energy and aerospace sectors, which it will employ to 3D print heat exchanger devices for the decarbonization system.

The UC Berkeley team, on the other hand, will focus on developing and applying sorbent materials for use in the system. The team will be led by renowned Professor of Chemistry Omar Yaghi, who’s known for being a leader in the area with experience in creating advanced systems capable of extracting targeted elements out of the atmosphere.

“Since the first crystallization and proof of porosity of metal-organic frameworks in 1995 and 1998, respectively, we have been continually developing their chemistry and design on the atomic/molecular scale,” Yaghi adds. “Teaming with GE on applying these materials in carbon dioxide capture is therefore a timely and most fortunate collaboration to address one of the most pressing problems facing our planet.”

Finally, the University of South Alabama team will be led by Prof. Grant Glover, and will provide support when it comes to material selection for the rest of the decarbonization system.

Glover said, “With the opportunity to pair these insights with the GE team that has expertise in manufacturing and product development, the possibilities of what we can bring to CO2 capture are quite exciting.”

A code red for humanity

The commencement of the project couldn’t come at a more relevant time, with the UN’s Intergovernmental Panel on Climate Change (IPCC) having recently released its landmark climate change report.

Dubbed a “code red for humanity”, the report warns of increasingly extreme environmental conditions and the breaking of a key temperature limit in just over a decade as a result of ongoing greenhouse gas emissions. However, UN scientists say that catastrophe can be avoided if governments and industries act fast with projects like GE’s carbon extraction system.

Moore adds, “Through this project, we’re aiming to demonstrate the feasibility of a system that could become a future large-scale, economical solution for widespread decarbonization of the energy sector.”

Environmental concerns such as energy use, material consumption, and carbon emissions are more prominent than ever in the 3D printing industry. Earlier this month, 3D printer manufacturer Stratasys furthered its commitment to achieving circular economy processes, climate action, and social change by establishing its Stratasys Sustainability function. Having appointed Rosa Coblens as its Vice President of Sustainability, the company is seeking to pursue its sustainability agenda based on the United Nations’ (UN) Sustainable Development Goals (SDGs).

Elsewhere, 3D printing materials develop Polymaker recently launched a new PLA-based filament for 3D printing, PolyTerra PLA, which has been developed to be tougher with less of an environmental impact. To achieve this, Polymaker significantly reduced the amount of raw PLA in the filament by compounding it with other organic materials.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a metal 3D printed heat exchanger. Photo via GE Research.