It’s 9:36 EST in the United States as I write, and as of right now Functionalize has $6,657 worth of Kickstarter backers on Day 1 of its campaign for what the company claims is a “breakthrough electronically conductive filament.” Mike Toutonghi, founder, CEO and chief scientist speaks about new 3D printing possibilities, saying, “Imagine a world where you can 3D print your next cell phone, a drone, an Internet of Things device, or the latest in wearable electronics, complete with circuits and electrical components.”

According to Functionalize, the new filament, Functionalize F-Electric, is “one thousand times more conductive than filament available today, and “enables anyone to print circuits, wires, sensors, power connectors, and other electrical components inside projects printed from popular PLA-capable 3D printers.” Functionalize is seeking $100,000 from the Kickstarter community to set up a production facility to bring F-Electric to market in volume.

Though they may have some competition soon with Graphene 3D’s upcoming filament release, most of the existing plastic conductive filaments are used for anti-static, static dissipative conduction of electric current, and the screening of electromagnetic interference shielding. You can indeed print in many different metals, such as copper, gold, aluminum and bronze.

Measuring under 1 ohm/cm, F-Electric is supposedly “the world’s most electrically conductive 3D printing (plastic) filament that enables electronic or electromechanical capabilities to be designed right into the structure of printed parts.” Current conductive 3D filaments measure in the 1,000 – 10,000 ohms/cm range.

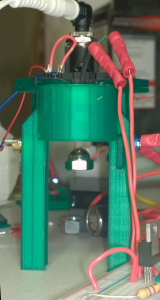

Here’s a brief summary of the origin story: On his 50th birthday, Mike and his son agreed to work on an electromagnetic propulsion project for his school’s science fair. He wanted to use his 3D printer to print the circuits inside the plastic, because he found out he was not a natural at soldering. He became obsessed with creating conductive material, learned a great deal about material science, and built a nanotechnology lab in his house!

Where it all started:

After years of experimentation and many failures, he finally was able to synthesize a mixture of graphene, metal, and plastic nano composites. He had finally created a printing plastic that can be used with existing 3D printers, as well as a “nanomaterials production process that provides the foundation to create many types of new, functional materials that product makers will need for the next wave of the personal industrial revolution.”

Matt Johnson, program director at Intentional3D, Inc. chimed in, saying, “By allowing electrical circuits to be part of the 3D design and build process, there are endless possibilities for what can be built. We see numerous applications across many industries and think Functionalize has just begun to scratch the surface of possibilities.”

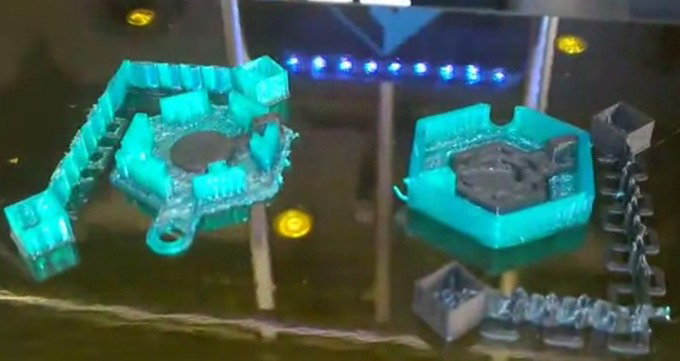

Backers for Functionalize, depending on the level of support, will receive access to “first-of-a-kind” products built using its electrically conductive thermoplastic material, including a 3D printed keychain flashlight, 3D printed levitator, as well as a variety of ‘Makers Kits”, including kits for product creators, educators, and master builders. If you back Functionalize for $71, you can get a ½ lb of the filament shipped to your house by March, 2015.