3D printing software company Castor has launched a free trial version of its software designed for automating part identification for additive manufacturing. This news follows after Castor introduced a novel capability that visualizes 3D parts from 2D drawings.

During the free trial period, users can analyze and evaluate the potential advantages and benefits of utilizing additive manufacturing (AM) for selected parts. This enables them to make informed decisions based on a comprehensive analysis, considering material properties, cost-effectiveness, digital supply chain benefits, and environmental impacts.

“Our mission is to help every engineer reduce the time and effort required to identify the opportunities for Additive Manufacturing,” says Omer Blaier, Co-Founder and CEO of CASTOR. “Through the Trial, we want to enable every engineer experience the value of our software firsthand.”

Optimizing AM processes with CASTOR software

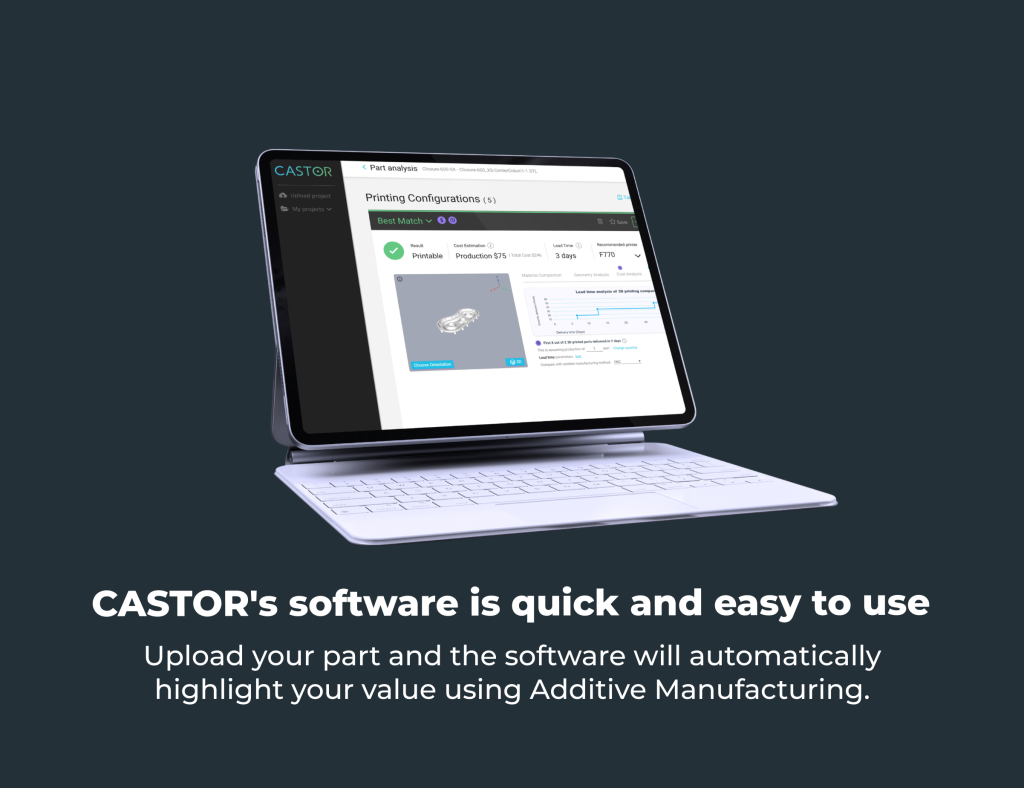

A key feature of the trial version is that the software’s analysis recommends optimal combinations of 3D printers and printable materials, depending on specific part requirements. Additionally, it estimates production costs, lead times, CO2 emission savings, and provides a visualization of the break-even point between different manufacturing methods. Engineers can swiftly identify suitable parts for AM, significantly reducing the time-to-market for AM projects.

Moving beyond the trial version, CASTOR software’s full version is designed to identify suitable parts at scale. This version possesses advanced capabilities that can analyze thousands of parts simultaneously, identifying conditions to leverage AM from technical, economical, and sustainable perspectives, says the company. It caters to new adopters and AM experts, offering tools to enhance efficiency by identifying weight reduction and part consolidation opportunities.

The software’s unique capabilities include a tailored Finite Elements Analysis, providing a quick assessment of a part’s likelihood to fail. This feature adds depth to the software’s capabilities, delivering valuable insights to optimize AM processes, says Castor.

Elevating collaboration and efficiency with advanced software offerings

Berlin-based 3D printing startup Quantica announced the integration of MultiSlice, an artificial intelligence (AI)-driven software, into its NovoJet multi-material 3D printing technology. This software was developed by Charles University spin-off Additive Appearance. MultiSlice software utilizes advanced algorithms and AI for precise 3D model predictions. NovoJet OPEN 3D printers, featuring MultiSlice, are set to ship in Q1 2024. The collaboration between Quantica and Additive Appearance aims to enhance NovoJet OPEN technology, focusing on superior control over voxel-level physical properties, including mechanical attributes and visual characteristics like color.

3D CAD software provider Dassault Systèmes launched a novel version of its 3D design and engineering software, dubbed SOLIDWORKS 2024. Key features include the ability to store SOLIDWORKS data in a previous release, promoting collaboration with users on older software versions. The Collinear Dimension Command addresses crowding issues in dimensions, streamlining the design process. With Cloud Services integration, users can connect to Dassault Systèmes’ 3DEXPERIENCE platform, enhancing data management and collaboration. Additionally, SOLIDWORKS 2024 introduced the 3DEXPERIENCE Transition Assistant and multiple enhancements across design disciplines for improved efficiency.

Read all the 3D Printing Industry coverage from Formnext 2023.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Castor’s software streamlines the AM processes. Photo via Castor.