As the world completes yet another hottest year on modern record due to the human use of fossil fuels, our young species is now coming to terms with the fact that something must be done with the pollution that results from our industries. In tackling these problems that affect our entire collective, though vulnerable populations see a disproportionate amount of suffering, we humans have come up with some our most ingenious innovations, including capturing solar power from space and harnessing the pollution itself for human use. Now, a team of interdisciplinary researchers at UCLA has looked to simultaneously target two birds with one stone by 3D printing building material from carbon dioxide emissions.

The second most consumed material on Earth, we use about three tons of concrete per person per year. Through the fossil fuels used to heat the kiln to create cement, as well as the calcination process involved itself, account for 5% of the Earth’s greenhouse gas emissions. More than that, CO2 emissions from power plants worldwide make up the largest source of greenhouse gasses overall. To make progress towards limiting the use of concrete, while also reducing CO2 emissions from smokestacks, a ULCA team made up of professors J.R. DeShazo, Gaurav Sant, Richard Kaner, Laurent Pilon, and Matthieu Bauchy came upon a unique solution.

Though they are still in the experimental stage, the team is working on a closed-loop process in which carbon from power plant emissions is captured and formed into a new material for use with 3D printing. Prof. DeShazo describes the motive behind their CO2NCRETE material. “What this technology does is take something that we have viewed as a nuisance—carbon dioxide that’s emitted from smokestacks—and turn it into something valuable,” DeShazo says. “I decided to get involved in this project because it could be a game-changer for climate policy,” DeShazo said. “This technology tackles global climate change, which is one of the biggest challenges that society faces now and will face over the next century.”

So far, attempts to capture carbon pollution have only reached for possible applications of the gas. DeShazo’s team is among the first to actually turn it into a building material. “We hope to not only capture more gas,” he explains, “but we’re going to take that gas and, instead of storing it, which is the current approach, we’re going to try to use it to create a new kind of building material that will replace cement. The approach we are trying to propose is you look at carbon dioxide as a resource—a resource you can reutilize. While cement production results in carbon dioxide, just as the production of coal or the production of natural gas does, if we can reutilize CO2 to make a building material which would be a new kind of cement, that’s an opportunity.”

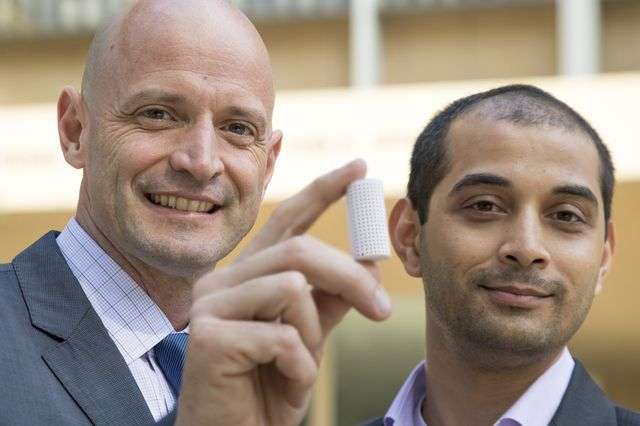

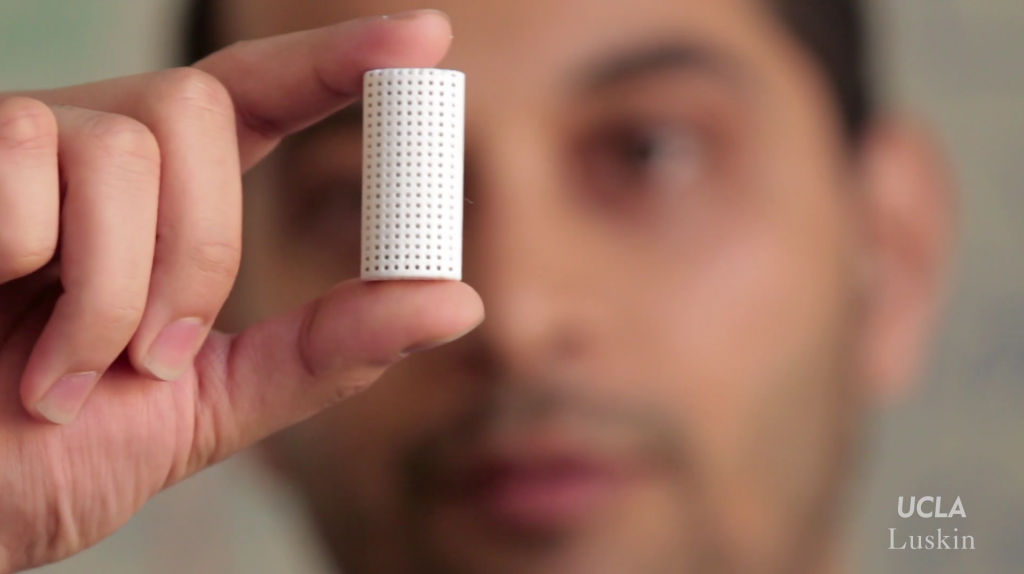

The team has developed a proof of concept int the lab that has seen them use 3D printers to fabricate small cones. The next step is to commercialize the ability to scale up the material collection and fabrication process. Prof. Sant explains, “We can demonstrate a process where we take lime and combine it with carbon dioxide to produce a cement-like material. The big challenge we foresee with this is we’re not just trying to develop a building material. We’re trying to develop a process solution, an integrated technology which goes right from CO2 to a finished product.” He continues, “3-D printing has been done for some time in the biomedical world, but when you do it in a biomedical setting, you’re interested in resolution. You’re interested in precision. In construction, all of these things are important but not at the same scale. There is a scale challenge, because rather than print something that’s 5 centimeters long, we want to be able to print a beam that’s 5 meters long. The size scalability is a really important part.”

Once this has been accomplished, and the commercialization process begins, the team plans to target both the US, where coal plants are prevalent, as well as China and India, where greenhouse gas emissions are also extremely high. In particular, China is the largest producer of such gases, while India is soon to pass the US at number two. To do so, however, there needs to be a complete shift in consciousness associated with fuel and production technology, DeShazo says. And they’re looking to cause this shift through economic incentives. “This technology could change the economic incentives associated with these power plants in their operations and turn the smokestack flue gas into a resource countries can use, to build up their cities, extend their road systems,” DeShazo says. “It takes what was a problem and turns it into a benefit in products and services that are going to be very much needed and valued in places like India and China.”

Of course, carbon capturing is only a medium-term solution to a long-term problem. Because fossil fuels are only in limited supply, the process would help to use pollution from existing power plants, but as the economy shifts towards a more sustainable model, there will be less carbon to recover. During this interim period, however, the UCLA team has discovered what could be the perfect bridge to a sustainable future.