Farsoon Technologies has partnered with Hyperganic and BASF Forward AM to develop an integrated solution for creating lattice structures using additive manufacturing.

This collaboration seeks to enable users to produce high-performance lattice structures efficiently on their first attempt. Oliver Li, Managing Director of Farsoon Europe, said, “Our open-platform hardware is capable of integrating a wide range of materials and software, making it ideal for swiftly bringing industrial products to market, leveraging Hyperganic’s technology to democratize lattice generation and accelerate the development of next-generation products. Our partnership with BASF Forward AM and Hyperganic will introduce integrated and accessible additive manufacturing solutions for industrial users, and highlights our commitment towards driving innovation within the industry.”

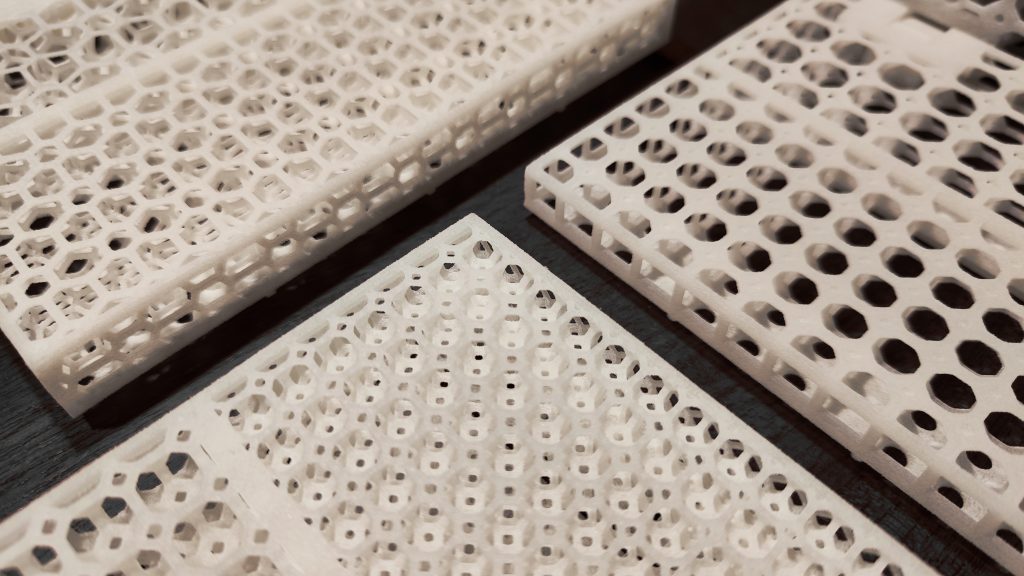

At Formnext this week, Farsoon will showcase demonstration parts created using the Ultrasim 3D Lattice Engine at Hall 11.1, Booth C11. BASF Forward AM will host a Lattice Generation Workshop at Hall 12.1, Booth D61 on Thursday, November 9, from 10:30 to 11:30 a.m.

A collaborative effort paves the way for accessible lattice generation

Central to this partnership is the Ultrasim 3D Lattice Engine, driven by Hyperganic’s software and enhanced by BASF Forward AM’s material proficiency. Farsoon has furthered this collaboration through rigorous testing. As a result, this joint endeavor has successfully characterized lattice structures constructed from Ultrasint TPU 88A on Farsoon hardware, resulting in verified lattice designs.

According to the company, this advancement eradicates the need for expensive specialized tools, making lattice generation more accessible to a broader audience. Farsoon anticipates that users will have the capability to craft their own lattice applications utilizing pre-established and authenticated lattice and printing configurations.

“Engineering structures has been an endless game of trial and error. Hyperganic catalyzes engineering knowledge into accessible workflows,” says Markus Finke, Director of Sales and Business Development at Hyperganic. “Through this partnership with Farsoon and BASF Forward AM, this vision is realized for thousands of their users, enabling them to perfect lattice structures from the outset.”

At the RAPID + TCT event this year, Hyperganic and BASF Forward AM initially unveiled the Ultrasim 3D Lattice Engine. This platform simplifies lattice design by integrating material and printing combinations, enhancing user-friendliness. Farsoon’s contribution to this partnership augments the established software and material proficiency with added hardware capability.

Unlocking the potential of lattice 3D printing

City University of Hong Kong (CityU) researchers devised a method to make 3D printed polymeric lattice components 100 times stronger. Unlike traditional heat treatments, which sacrifice flexibility, this approach partially carbonizes the components, enhancing robustness while maintaining twice the ductility. This innovation allows for the creation of highly durable and versatile 3D prints suitable for applications like coronary stents and bio-implants. The process offers a cost-effective and scalable means to produce lightweight, strong, and ductile mechanical metamaterials in various geometries, with significant industrial potential.

Engineering software developer nTop unveiled its third-generation latticing technology for 3D printing applications. Offering user-friendly lattice design tools, the release simplifies complex lattice structures with 37 blocks developed over 22 months. The software streamlines lattice generation in three steps: unit cell selection, cell map definition, and parameter control. Notably, it enhances performance, expediting the creation and optimization of lattice designs for diverse applications, saving time, and enabling design experiments for optimization.

Production service provider Rapid Product Manufacturing (RPM) secured a research grant to create complex 3D printed lattices for consumer goods. Using Carbon Digital Light Synthesis (DLS) technology and EPU41/EPU40 materials, RPM planned to develop complex elastic structures with potential in both industrial and consumer applications.

Voting has now started for the 3D Printing Industry Awards 2023. Cast your vote now!

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows A variety of 3D lattice structures produced with Ultrasint TPU 88A on Farsoon Plastic PBF system. Photo via Farsoon Technologies.