Flowbuilt Manufacturing, a registered trademark of premium shoe insole developer Superfeet, has opened its first footwear manufacturing facility in Ferndale, Washington. Powered by 3D printing, multi-section injection molding, and 3D scanning, the new facility will see through the mass customization of limited-run shoes for rapid prototyping, sampling and development.

“To date your choices have been very limited when it came to finding the best resources to bring footwear from ideation to fruition,” says Eric Hayes, Superfeet Chief Marketing Officer, “until now,”

“We’ve created the new standard for footwear manufacturing and are setting up our partners for success by solving for problems that have yet to be discovered.”

3D printed insoles

Headquartered in the UK, Superfeet has over four decades of experience in the production of comfortable insoles and footwear. Noticing the potential to create better form-fitting shoes, the company has turned to 3D printing and foot-scanning as a potential solution.

In 2017, Superfeet released the ME3D 3D printed insole range, produced in partnership with rs scan International, injection molding company DESMA and HP.

In addition to multi jet fusion (MJF) technology for custom insole production, HP provided data collection intelligence to the project, packaged as the FitStation platform.

Delivering the future

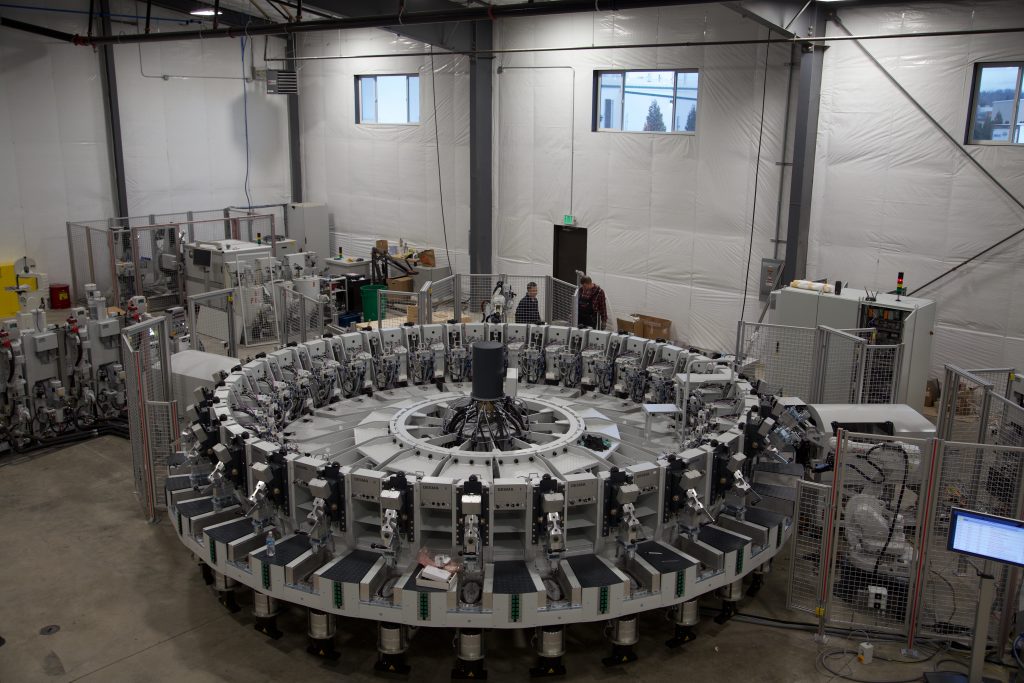

FitStation is a platform that collects biometric data of person’s foot, enabling Superfeet to create formfitting products. FitStation technology will also be used in the design process at the new Flowbuilt facility, and DESMA is providing multi-section injection (MSI) machinery.

Chuck Sanson, Director of Business Development at Flowbuilt Manufacturing, comments, “As evidenced in our own experience bringing technologies like FitStation and ME3D products to market, we set out to create a clear path for brands to design and deliver their future before anyone else can.”

Brooks Running Company has been confirmed as Flowbuilt’s first performance footwear partner. Personalized running shoes from this partnership are expected to be released through select retail partners June 2018.

Sanson concludes, “Superfeet is excited to push the capabilities of Flowbuilt and showcase the advanced manufacturing technologies that can be found right here in the USA.”

Keep update with consumer applications and more – subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a change of scene? Sign up to 3D Printing Jobs here.

Featured image shows a sign for the Flowbuilt 3D Print Lab. Photo via Flowbuilt Manufacturing