Desktop 3D printer manufacturer FlashForge USA has begun taking pre-orders for a new desktop machine with potentially wide-ranging dental manufacturing applications.

Unlike many resin 3D printers, the Hunter S is open-material, meaning that it’s capable of accurately creating crowns, bridges, models, surgical guides and other dentistry parts from a broader third-party pool of materials. Already, FlashForge USA has validated 3D Systems’ NextDent resins for the system, indicating the profile of FDA approved and biocompatible polymers adopters stand to benefit from.

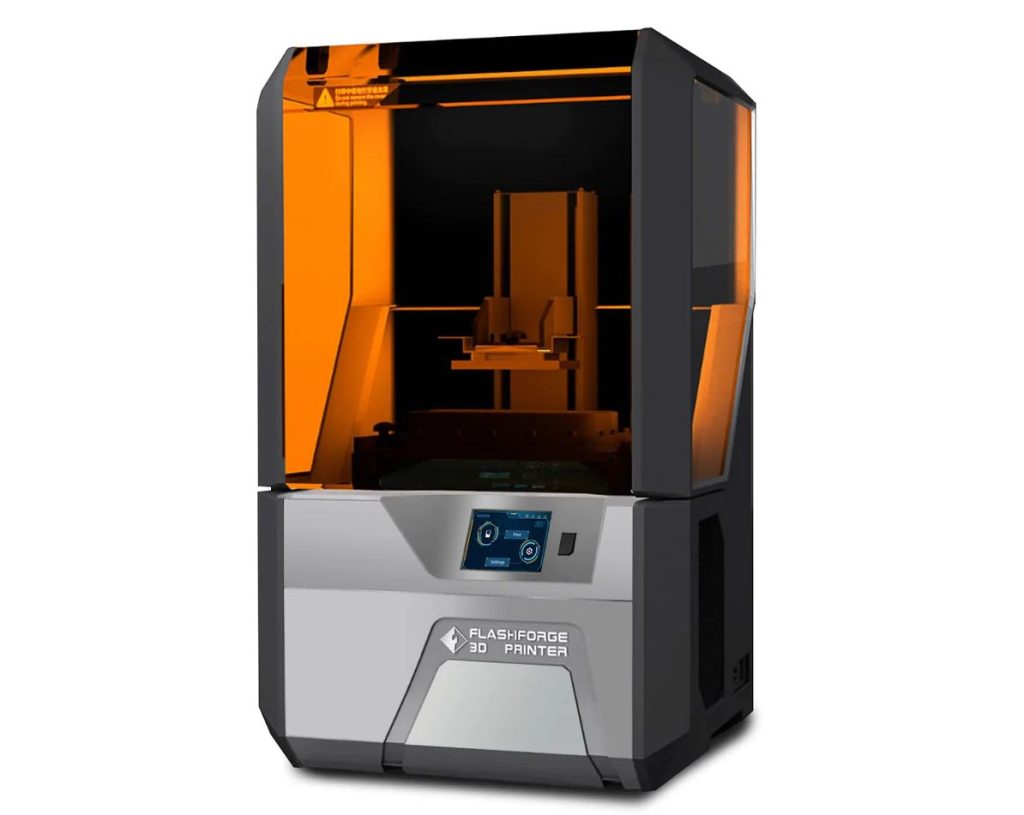

Introducing the Hunter S 3D printer

The Hunter S is powered by a Texas Instruments light engine that’s built to guarantee a high degree of reliability and print quality. Not only does the system have a 50,000-hour lifespan, but its linear motion guide actuator ensures sustained LED intensity, thus enabling stronger print stability and the realization of parts with fine details.

In terms of capacity, the Hunter S comes with a 144 x 81 x 150 mm build volume and durable, easy-to-detach plate that can be removed without needing calibration. Likewise, the machine’s resin vat is designed to facilitate rapid replenishment, and its FEP vat film is said to be cheap and easy to replace, making both processes quick and painless.

A digital dentistry solution?

FlashForge USA is marketing the Hunter S as a high-precision 3D printer with a speed, accuracy and low operating cost that “make it the perfect choice for denture manufacturers, dental laboratories and clinical users.” In particular, the company has sought to focus on the possibilities unlocked via its system’s third-party material compatibility, by producing a series of demonstrators from other brands’ resins.

Already, FlashForge USA says it has “extensively” tested 3D Systems resins on the machine. As such, Hunter S adopters can safely deploy the firm’s NextDent range, which includes everything from splint and retainer 3D printing materials to polymers for frames and supports, knowing that FlashForge USA has tested their efficacy.

When it comes to other third-party resins, the company has used the Hunter S to 3D print Dentona materials. Using Dentona’s Splint/Guide resins, the firm’s engineers have been able to develop guides with a similar biocompatibility to those made via its own FHD 1500 resin. With the company’s Cast resins, it has also found it possible to produce purple-colored crowns and bridges, effectively illustrating the potential applications unlocked by the machine’s open-material philosophy.

Technical specifications and pricing

Below are the technical specifications for FlashForge USA’s Hunter S 3D printer. Customers can pre-order the Hunter S now, with delivery scheduled for December 2022.

| Technology | Digital Light Processing (DLP) |

| Build Volume | 144 x 81 x 150 mm |

| Pixel Size X/Y | 75 μm |

| Light Source | 405nm LED |

| Print Speed | 10-30mm/h |

| Screen | 3.5-inch colorful IPS touch screen |

| Printer Dimension | 360 x 310 x 565 mm |

| Net Weight | 17.8 kg |

| Connectivity | Thumb Drive/USB Cable/Wi-Fi |

Nominations for the 2022 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Let us know by casting your vote now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows FlashForge USA’s Hunter S 3D printer. Image via FlashForge USA.