Nominations for the 2022 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Let us know by casting your vote now.

US 3D printer manufacturer nano3Dprint has announced plans to introduce a new dual-dispensing machine with the potential to “revolutionize 3D printed electronics.”

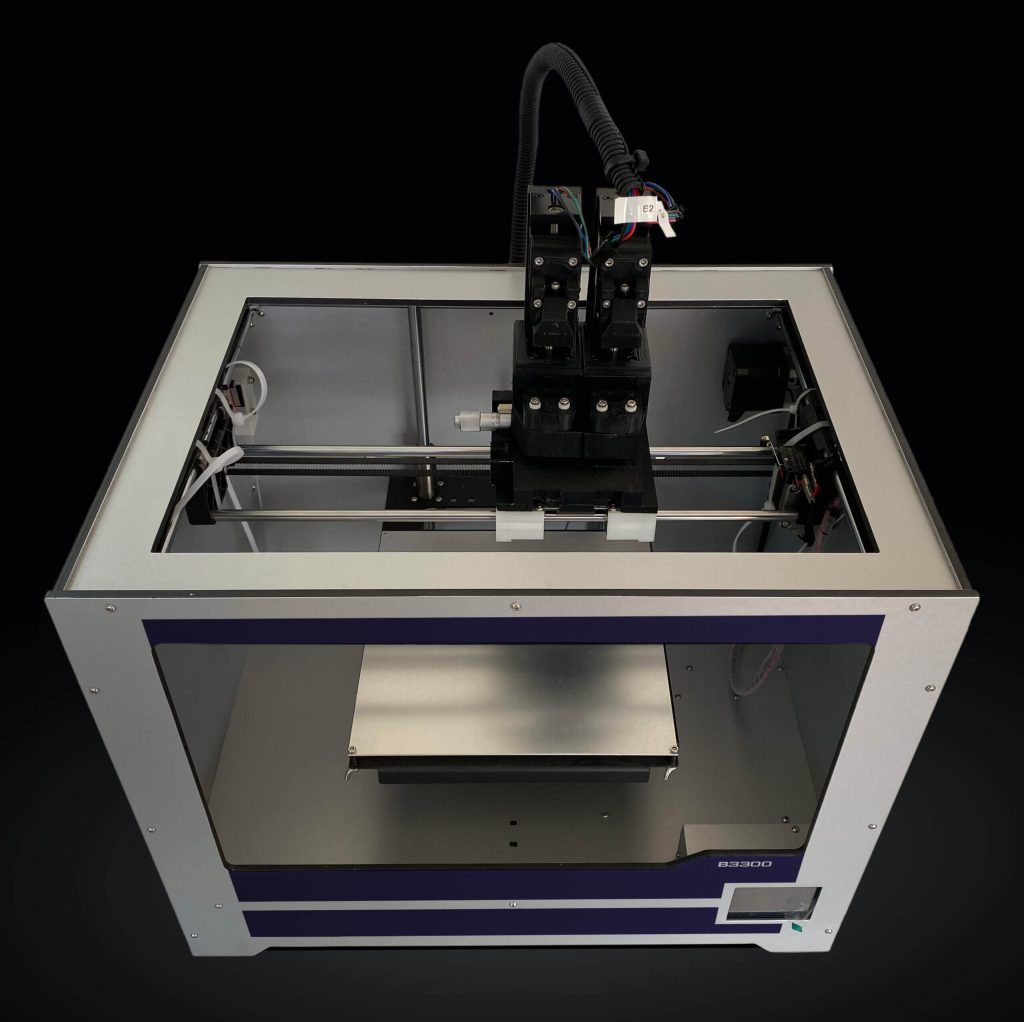

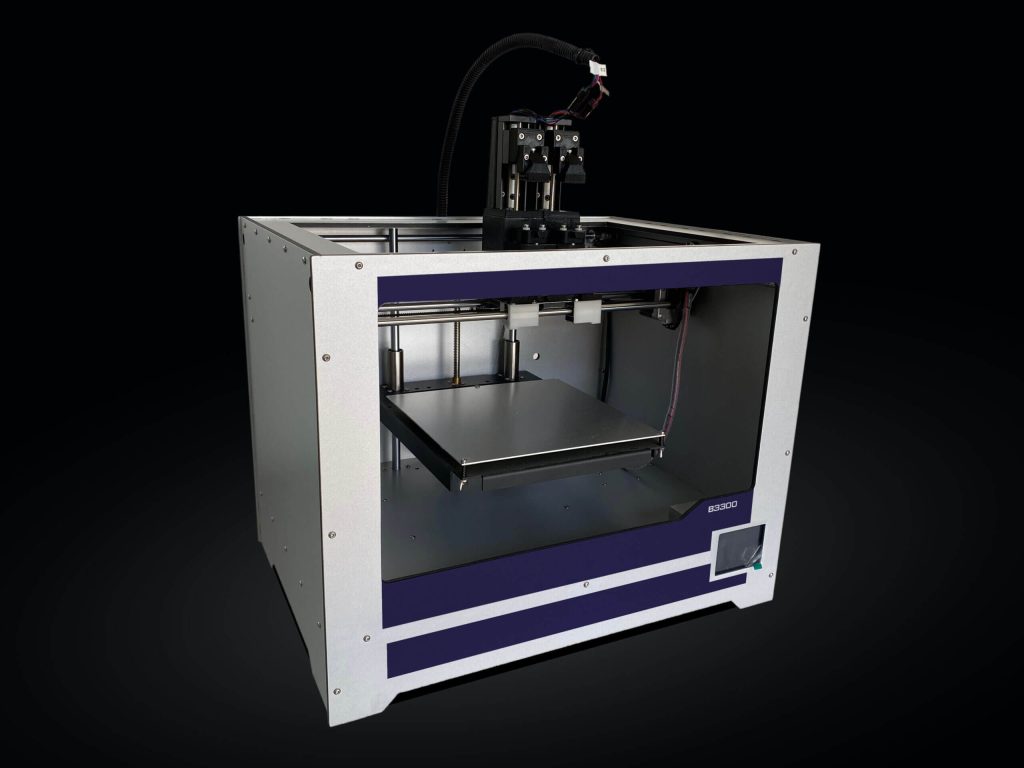

Featuring a unique dual-material dispensing system, the nano3Dprint B3300 is capable of simultaneously printing multiple different conductive and functional inks onto an existing substrate, in a single pass. According to its developers, this makes the machine ideal for producing turnkey electronics, with wide-ranging applications in the medical, agriculture, solar and consumer goods industries.

“The B3300 can print wearables with embedded conductors, cellphone parts with internal antennas and electronic devices with internal sensors,” explains nano3Dprint Product Success Manager, Gretta Perlmutter. “It allows for incorporating sensors, strain gauges, heaters, complex antenna geometries and optical components into a 3D print.”

“This is a revolutionary development within the electronics 3D printing industry; new combinations of materials difficult to print together, can now easily be printed in combination with the B3300.”

nano3Dprint’s electronics 3D printers

Based in California, nano3Dprint specializes in the development of economical electronics 3D printers. Soon to be joined by the B3300 and the new ‘D4200S,’ the firm’s sole current offering is the A2200 3D printer. Like the B3300, nano3Dprint’s current system is a multi-material electronics 3D printer, but it doesn’t include the same dual-dispensing setup, and operates with dual extruders instead.

Despite featuring scaled-back specifications compared to the company’s upcoming machine, the A2200 is still capable of printing structural pastes and conductive inks side-by-side, as a means of forming antennas, sensors, medical devices and other products with embedded functional materials.

nano3Dprint markets its portfolio as having “endless” applications, from the design, R&D and production of wearables, to the manufacture of robots, batteries and wires for lighting up standard prints. The company also boasts that its offering can be used to layer plastics and create “the strongest 3D prints available with composite materials,” though its new system appears to be solely electronics-focused.

Drawing on its extensive scanning probe and nanotechnology expertise, nano3Dprint is preparing to bring a micro-to-nanoscale printer to market as well. While the D4200S remains without a price or picture on the company’s website, it’s understood to have a broader potential reach, targeting prototyping and industrial applications, in addition to electronics customers.

Introducing the dual-dispensing B3300

At the core of the B3300 is a proprietary dual-dispensing toolhead, which enables the deposition of multiple materials together. The machine’s broad compatibility means it can process materials with a viscosity of anything from 1 to 54,000 millipascal second (mPa·s). As such, the upcoming printer is set to be compatible with materials like gold and silver, as well as UV curable polymers and silicone.

In order to ensure print quality, adopters can also take advantage of the printer’s video inspection system, which allows for remote progress monitoring in real-time. nano3Dprint says that doing so enables users to make sure prints have an “accurate layer height, surface finishing, tolerance and roundness,” in addition to the desired level of feature resolution.

Accuracy-wise, the B3300 will be capable of depositing inks or pastes at a trace width of 0.2 mm, with users being able to control independent vertical movement for each dispensing nozzle. In practice, this means the system will allow for the creation of multi-material 500-micron layers in a single pass, and provide users with the ability to produce electronics with wearable, PCB and sensor applications.

Technical specifications and pricing

Below are the technical specifications for nano3Dprint’s B3300 3D printer. The company is currently taking pre-orders for the machine at $6,000, with shipping set to begin on October 17, 2022.

| Build Volume | 214 x 186 x 160 (mm) |

| Printheads | Dual Materials Dispensing System |

| Nozzle Size | 1.6 mm to 150 μm |

| Print Layer Height | ≥ 0.02 mm |

| Max. Heat Bed Temp. | 100°C |

| Positional Accuracy | XY axis: 0.11 mm Z axis: 0.0025 mm |

| Dimensions | 467 x 357 x 374 mm |

| Weight | 13 kg |

| Connectivity | SD Card, Flash Drive |

| Material Compatibility | Functional Pastes and Inks, Conductive Paints, |

| Solvent-based Inks, Silver Nano-Particle Inks | |

| and Graphene-loaded Materials |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows nano3Dprint’s B3300 electronics 3D printer. Image via nano3Dprint.