This week a handful of enterprises from the 3D printing industry are kicking off 2018 with exhibitions of their products at CES 2018 in Las Vegas.

In addition to a material announcement, Formlabs is showcasing the Fuse 1 desktop SLS 3D printer at a tradeshow for the first time.

Up until now, Formlabs forthcoming SLS technology has only been seen as samples at shows, and demoed at an exclusive launch event in June 2017.

What we know about the Fuse 1

The Fuse 1 is Formlabs’ first selective laser sintering (SLS) 3D printer. Development of the system started around the time the Form 2 SLA 3D printer was released back in 2015. It is the product of a demand for industrial quality 3D printing in a compact package, and will join several manufacturers hoping to make SLS 3D printing more affordable.

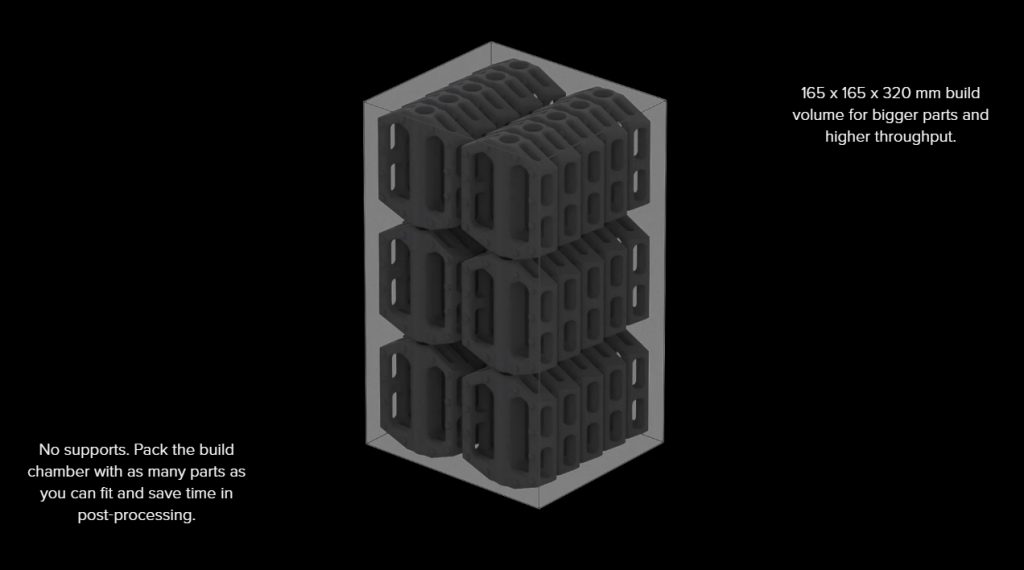

A single Fuse 1 system takes up a 677 x 668 x 1059 mm square of bench space. The build volume measures 165 x 165 x 320 mm – a stackable workspace ensuring optimal use.

As with many SLS systems, the build chamber of the Fuse 1 can be removed and replaced with a fresh box to start a new job. This reduces the amount of downtime between prints, as parts all left to cool/be cleaned. In addition, each chamber can be filled with up to 50% recycled material feedstock, a helping hand for both cost and an environmental conscience.

Dependent upon material, the Fuse can achieve a minimum layer thickness of 100 µm, and reach maximum build speed of 10 mm per hour.

First commercial shipments of the Fuse 1 3D printer are expected mid 2018.

New materials

Again created to “drive 3D printing into more end-use applications,” Formlabs has also launched two new SLA resins for the Form 2 3D printer.

Grey Pro is an optically opaque resin designed for “precision and stiffness.” It is an upgraded version of the company’s Greyscale prototype resin, exhibiting good elongation at break point; high heat resistance; and low creep (likelihood of deformation).

Rigid Resin, by comparison, is reinforced with glass resin, offering very high stiffness and a polished finish.

According to Max Lobovsky, co-founder and CEO of Formlabs,

“We believe we can drive 3D printing into more end-use applications by dramatically improving material properties and significantly decreasing the cost per part, bringing the promise of 3D printed mass customization closer to reality for businesses and consumers.”

Formlabs will be also be at next month’s SOLIDWORKS World in L.A. from February 4-7, 2018. Custom 3D printed samples can be requested ahead of the event,

For more coverage of CES 2018 and other 3D industry related shows subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Nominate Formlabs and more in the second annual 3D Printing Industry Awards here.

Featured image shows the Fuse 1 3D printer in action. Clip via Formlabs on YouTube