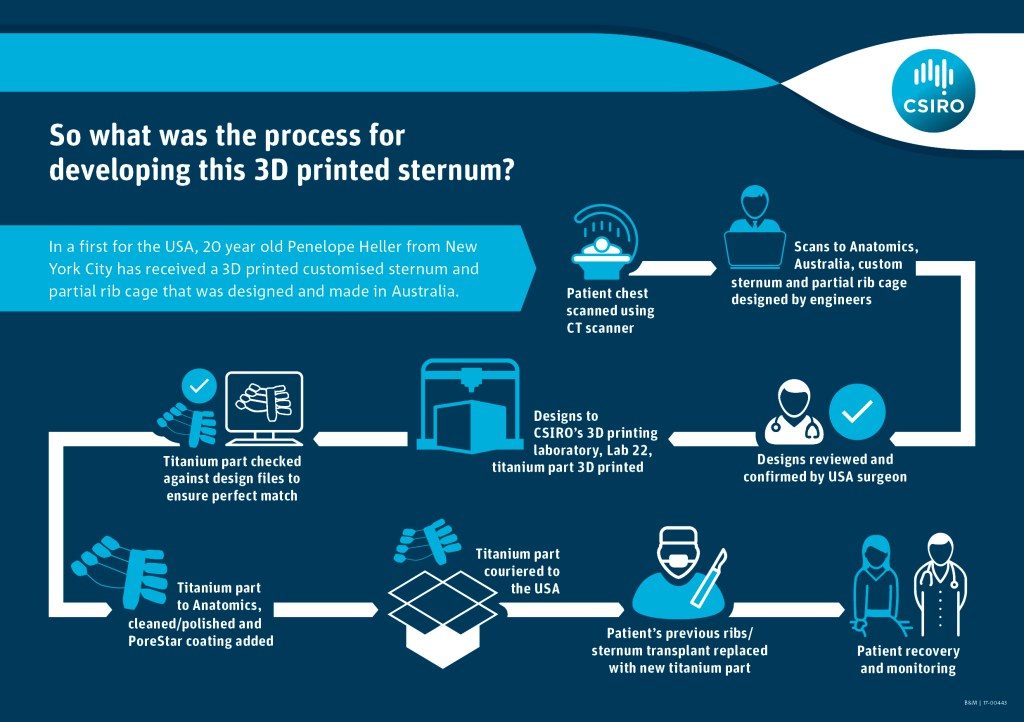

Australian med-tech company Anatomics and 3D printing service bureau Lab 22 at the CSIRO (the Australian federal government agency for scientific research) have successfully produced a composite sternum and rib cage implant for a patient in the US.

The implant was provided to a US surgical team, led by Jeffrey L. Port of the New York-Presbyterian and Weill Cornell hospitals, who successfully performed the implant procedure on 20 year old Penelope Heller.

Designing the implant

High resolution CT scans of the patient’s chest were taken in the US and uploaded AnatomicsRx software platform. It was then sent to Anatomics, which specializes in the manufacture of patient specific implants and designed the partial sternum and ribcage.

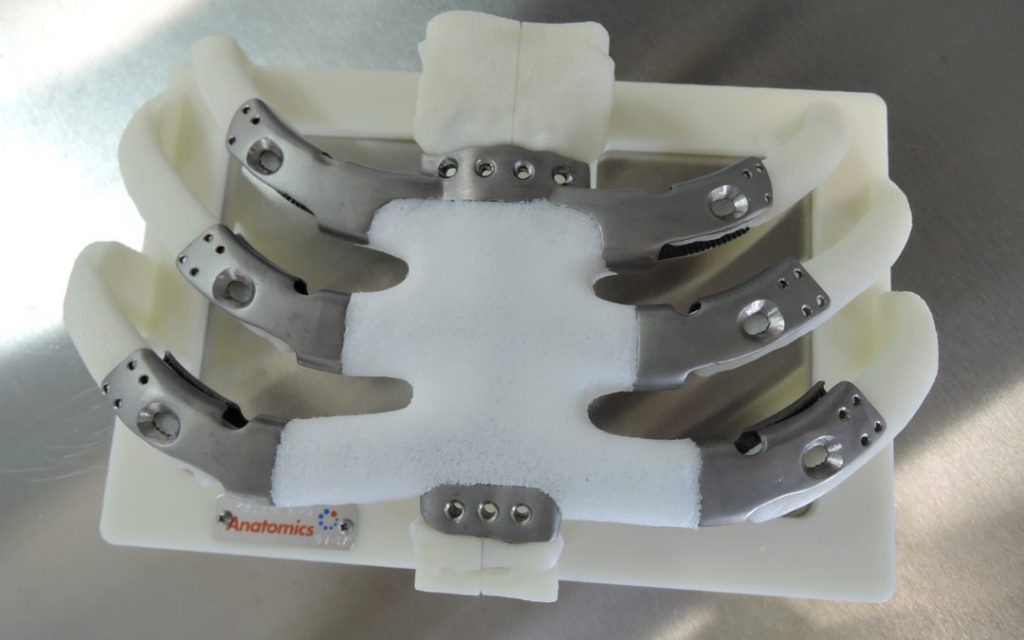

With the implant designs checked by Port, the build code was sent to the CSIRO’s Lab 22 3D printing facility. CSIRO 3D printed the implant using a mixture of titanium and PoreStar, a modified polyethylene material with porous, bone-like architecture for the different elements.

Scope for further application

Before this implant, Heller had originally received a standard GoreTex implant, which had constantly given her “breathing issues and pain”.

Since Anatomics is not currently cleared for use under the US Food and Drug Administration’s rules, the implant was made available to Heller via the FDA’s Expanded Access (Compassionate Use) Program.

Paul D’Urso, executive chairman of Anatomics, emphasised how the creation and application of this 3D printed implant only happened due to the willingness of all parties involved, noting that “it was a group effort that began with the patient’s pursuit of information.”

The latest in a number of successes

The first such operation, where a titanium implant combined with a synthetic polymer was used to replace a human sternum, happened earlier this year in the UK. Edward Evans received a 3D printed titanium and polymer sternum implant designed by Anatomics and produced by CSIRO.

Prior to that, the two Australian med-tech companies had successfully collaborated in producing a 3D printed fully titanium sternum.

For more stories on the successful medical application of 3D printed implants, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the 3D printed implant in theatre before surgery. Photo via CSIRO.