Filament weaves the tapestries of imagination. Without filament the desktop 3D printer is just a rather complicated paperweight. And the right filament can make or break a creative project. A project printed in the wrong filament is like taking jam made from Umpqua Valley blackberries picked in August and spreading it on crust-less white bread. The right filament can elevate a project to art.

Kickstarter allows people to invest individually in interesting ideas. The Virtual Foundry, makers of “Filamet: the Metalic Printer Filament for Artists and Makers”, is clearly interested in increasing the artistic options for people with desktop printers. They have launched a Kickstarter project to get their Filamet metallic filament manufactured.

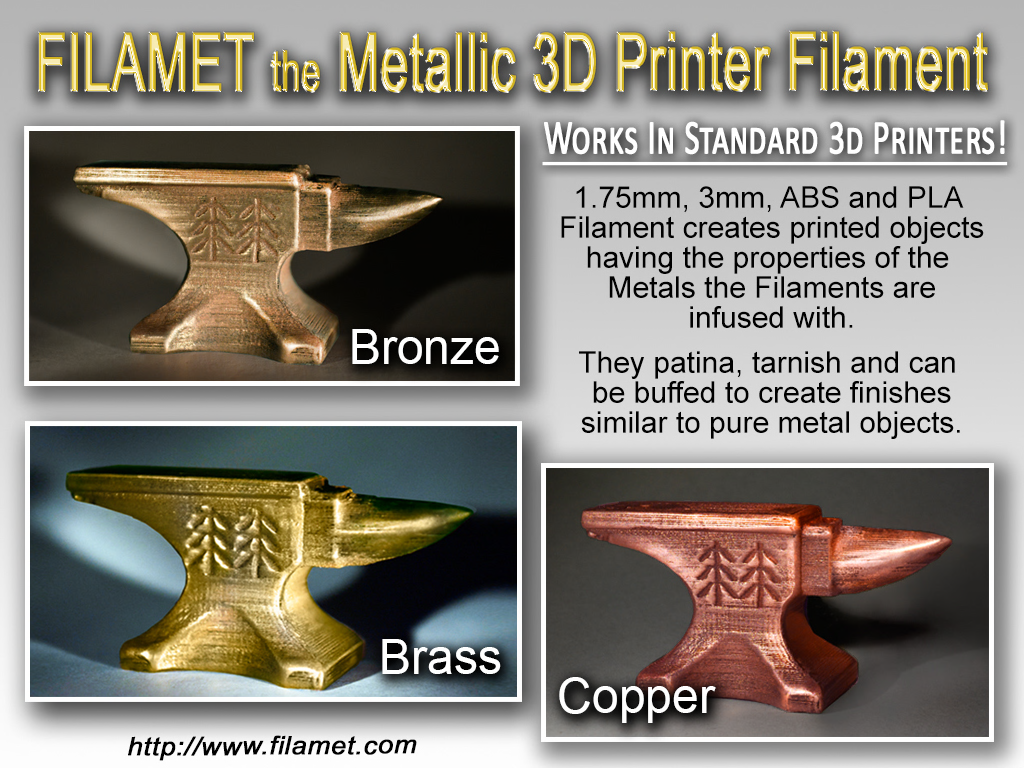

These Virtual Foundry repeatedly emphasizes a desire to increase affordability and accessibility of metallic filaments. Having produced samples of their printable metal, they say that Filamet is made of up of up to 85% pure metal, so authenticity is present, it seems. Naturally, the results won’t be identical to cast metal but this filament is intended to maintain the “vital properties” of metal: the printed works will be solid and heavy and cool to the touch.

Works printed with Filamet can be subject to patina and tarnish, and may be buffed to produce sculptures of great aesthetic similarity to cast metal works, according to the Kickstarter. The makers of Filamet are working to adapt jewelry tools to clean and modify finished prints, allowing for a greater flexibility in the making process. A single error doesn’t necessitate going back to square one. Along that vein, these tools could even be used to improve a final product or add unique details to finish the work.

The philosophy of the Virtual Foundry is a sort of “art-meets-engineering” ethos that is common in the Maker community. The team possesses an interesting array of talent that speaks to the potential success of the project. The “inventor and narrator” at the Virtual Foundry, Brad Woods, describes his “lifelong drive to create solutions to engineering problems.” He emphasizes his capacity for breaking down a problem into workable pieces.

Glenn Prescott is the team’s “Master Machinist and blacksmith” who also has a background in engineering and extrusion. Other than being perhaps the most metal job title ever, Prescott’s skill set provides the kind of perspective necessary to make a project like the reach physical reality.

William Howards is the Virtual Foundry’s “Certified Master Goldsmith and Master Jeweler.” His internationally-known school ‘The Howards Academy for the Metal Arts’ brings an element of name recognition to this “humble little project.” He is described as having an “eye for detail and exacting standards.” That’s exactly what is necessary for a project like this to succeed.

The current stage of the project is a little in the air. The extrusion of the filament is itself very simple; however, the high viscosity of the mixture might pose some issues, but say that they have succeeded at this in testing. The intention of the Kickstarter element is to reduce cost by allowing for the bulk purchase of raw materials, but the product will be marketed regardless of the Kickstarter results. The rewards offered for the investors range from “a T-shirt of style and taste” to a tiny metal anvil, to a sampler pack with brass, bronze, and copper filaments.

In the future, the Virtual Foundry intends on attempting a more drastic cost reduction. They developed their own powders during the testing process. At this stage, there are issues with scaling these methods and the additional variable is unwelcome, but employing these methods at a later stage could serve to make this product more affordable. As it stands, this filament seems to be a useful addition to the array of options for 3D printer.