The Food and Drug Administration has issued guidelines for 3D medical devices, which means it is one step closer to becoming an accepted part of the process.

The US agency rules food and drugs with an iron fist and its guidelines are essentially the bible for the respective industries. You can’t do anything in America without the organisation’s approval and it is now clearly warming up to 3D printing.

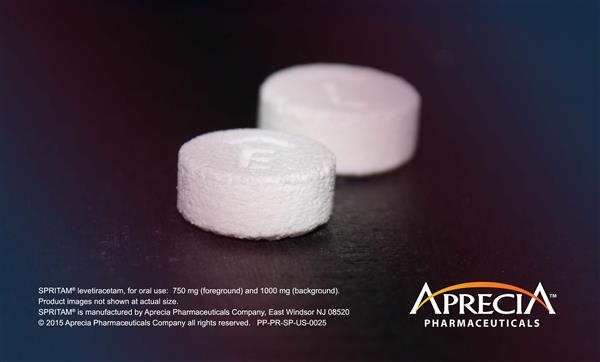

First drug to be 3D printed

In March it approved epilepsy drug SPRITAM, which used 3D printing to create a new coating and structure that allowed it to dissolve swiftly. 3D printing is also heavily involved in the production of medical devices and procedures, which the FDA has a hand in. At the time it was hailed as the start of a downloadable medicine revolution.

3D printing has changed the world of research and has so many applications in healthcare that it’s a case of prioritising and separating out the workload. It has the capacity to change cardiovascular medicine, implants and even transplants in the end. The Food and Drug Administration embracing the industry is a major step forward.

The ‘leap-frog’ draft guidance for medical device manufacturers provides advice and technical requirements for production and validation of the devices.

FDA recognises value of 3D printing

The FDA has recognised that 3D printing offers a number of advantages to the medical industry and is now keen to put the regulations in place that will let the industry adopt additive printing en masse. It presents its own problems when it comes to validation, but the governing body is keen to find solutions and recognises the worth of 3D printing.

“AM has the advantage of facilitating the creation of anatomically-matched devices and surgical instrumentation by using a patient’s own medical imaging. Another advantage is the ease in fabricating complex geometric structures, allowing the creation of engineered porous structures, tortuous internal channels, and internal support structures that would not be easily possible using traditional (non-additive) manufacturing approaches,” the FDA said.

Specific issues with 3D printers

The devices will obviously have to adhere to standard regulations, but 3D printing presents its own issues and the FDA has outlined the requirements for the devices to list every component material and the way it lays them down.

“The ratio of recycled to virgin powder can affect melting properties, which affects the energy needed to create consistent bonding between layers, which in turn affects [a device’s] final mechanical properties,”” said the FDA.

Some of the guidelines might require manufacturers to rethink their guidelines and production processes to adhere to certain regulations. Overall, though, the industry should welcome these guidelines as a clear attempt to bring 3D printing into the medical fold.

At the moment additive printing is on the sidelines, despite breaking new ground each and every day and contributing to some of the most remarkable medical work of our time.

3D printing goes mainstream

Now it can move out of the theoretical research and experimental surgery shadows and into the mainstream. The FDA seems willing to help with the process and we can now look forward to an even brighter future.

The guidelines don’t cover bioprinting, which is a minefield in itself and one that could keep the regulators busy for years to come. They also don’t even begin to address the concept of bioprinting food.

That is the next big movement on the agenda and it is sure to be a regulatory minefield, even when we have the technical aspects right.

The red tape is all part of the process, though, and with every document like this we get a step closer to additive printing becoming the force for good that we all know it can be.