About Vigyan Ashram (VA)

Dr. Kalbaag, PhD from University of Illinois, Chicago started with his dream project of Vigyan Ashram in 1983, at a small village Pabal near Pune city in India. Vigyan Ashram (VA) means science hermitage or a resident school, is a modern form of old Gurukul education system. Students learn science through experimentation, building various things, applying the knowledge gained to solve the real problems and become entrepreneurs. The various challenges in the areas of agriculture, energy, water, food and health are solved with innovative and cost effective approach. VA also has a FABLAB, which is the first outside Massachusetts Institute of Technology (MIT). The 3D printing facilities at FABLAB play a very important role in the design and manufacture of some of these solutions.

First FABLAB outside MIT

FABLAB is the educational outreach component of MIT’s Center for Bits and Atoms (CBA), an extension of its research into digital fabrication and computation. A FABLAB is a technical prototyping platform for innovation and invention, providing stimulus for local entrepreneurship.

In 2002, Prof Neil Gershenfield (Director, Center of Bits and atoms, MIT, USA) visited VA and the FABLAB was setup with capital equipment by NSF-USA and Indian Institute of Kanpur, India. This was the first FABLAB outside MIT.

Over the period of time, VA has collaborated with engineers, industries and academia from India, US as well as UK.

Various Projects

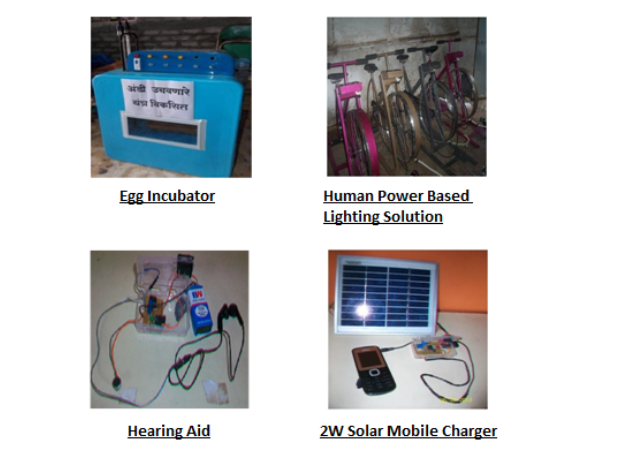

At FABLAB, various projects are executed where 3D printing is used during the concept stage or prototyping. The primary objective behind all these projects is to develop low cost solution and techniques; which can be manufactured by locals with little training. Some of the examples are as below.

- An Egg Incubator machine was developed initially from scrap material. Further, it was enhanced to achieve 92% success rate. At present, solar powered egg incubator is under development.

- Providing lighting facility for tribal communities is a challenge as they keep on changing their base. Grid/ Solar/ Wind generated electricity is not feasible due to various reasons. Therefore, a mono Wheel Genset is being developed with attachment to a mobility-bicycle. This generates power through a generator/alternator when pedaled daily, which is then stored in a battery and can be used in the evenings for illumination using LED lamps.

- A hearing aid, which is low cost, light weight and easy to repair & maintain, is being developed. At present it is under testing and available as a D-I-Y kit for students.

- VA innovated a low cost circuit for solar mobile charger. Currently, building the solar charger is part of students curriculum as well as it is also manufactured as per the customers’ demand.

Success Stories Continue

Now, VA FABLAB has started working on their next challenging project i.e. building a very cost effective prosthetic hand. The 3D printing facilities are being used in making the prototypes. The engineers, teachers and students truly believe in the mission of FABLAB that is ‘We can make almost anything!’