A team of scientists from UC Berkeley, California, have proposed a new 3D printing method for producing artificial tissues. Described to The Daily Californian as “like making a hamburger in a very cool — cryogenic — solution,” they believe this alternative process could be key to increasing the speed of 3D fabrication.

The results from a recent study of the method by the team were recently published in the ASME’s Journal of Medical Devices. It describes the basic principles of the so-called multilayer cryolithography (MLCL) technology, and its viability for producing simple, coherent structures.

How is 3D bioprinting like making a hamburger?

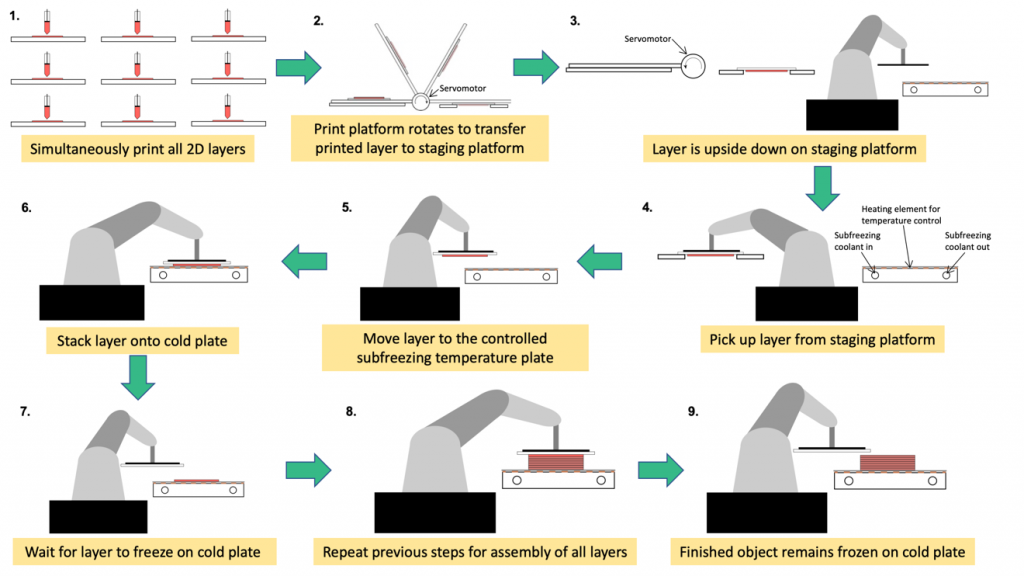

Though likened in many ways to 3D bioprinting processes, UC Berkeley’s MLCL technique is actually a kind of deconstructed 3D printing process. Instead of building up sequential layers of material until a structure is made, MLCL actually breaks up this process into a series of individual 2D layers. The 2D layers of material are deposited parallel to one another and simultaneously frozen. They are then assembled into the 3D structure and bound together.

A clearly finicky process Gideon Ukpai, one of the study’s co-authors explains, “We had some challenges with trying to transport the layers and assembling them. The layers binding together after the fact was also a challenge.”

Zichen Xiao however, another of the project’s researchers who likened the process to a frozen hamburger, described the success as, “You already print multiple layers, and you basically pick up one layer and stack them on top of each other. You put the bottom bread there first and put whatever layer you want on top of it.”

One of the main advantages of this process over more conventional 3D bioprinting processes that use bioinks and hydrogels, is that the matter is able to retain its shape. “By the process of freezing,” Xiao adds, “it keeps its rigid structure, and the cells are still alive.”

In the experiment, a structure containing 10 layers was made using MCLC on a modified Flashforge 3D printer. The results exist as a proof of concept for the method, and provide the team with a foundation for future work.

Cryogenic 3D bioprinting

So – is freezing the answer to better, faster 3D bioprinting? Other researchers are exploring the use of cryogenics in 3D bioprinting, including a team from Imperial College London in the UK. However the enhanced performance promised by such methods is still up for debate.

The next step for the UC Berkeley team is to optimize the MCLC process, characterize the products, and also “determine the appropriate scenarios that present the most advantages.”

Full results of this team’s most recent study of the method, titled “A parallel multiple layer cryolithography device for the manufacture of biological material for tissue engineering,” are published online in ASME’s Journal of Medical Devices. The paper is co-authored by Gideon Ukpai, Joseph Sahyoun, Robert Stuart, Sky Wang, Zichen Xiao and Boris Rubinsky.

Vote for your Research Team of the Year in the 2019 3D Printing Industry Awards.

For more of the latest research news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in academia? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

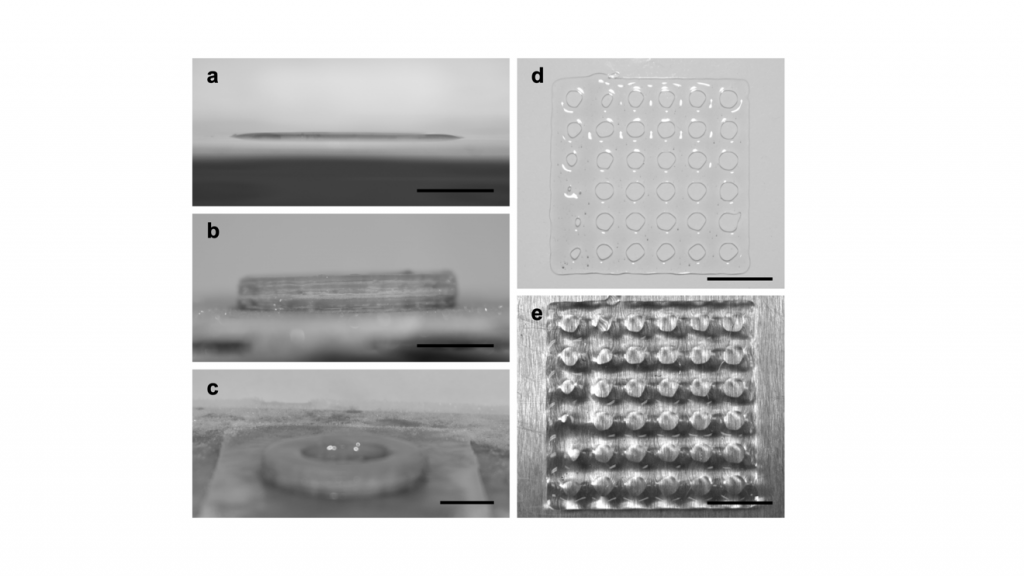

Featured image shows complex ring and grid shapes fabricated using UC Berkeley’s multilayer cryolithography method. Image via ASME Journal of Medical Devices