Chinese SLM and SLS 3D printer manufacturer Farsoon, has introduced it’s latest Laser Beam Powder Bed Fusion (LPBF) large-format metal 3D printer, the FS621M.

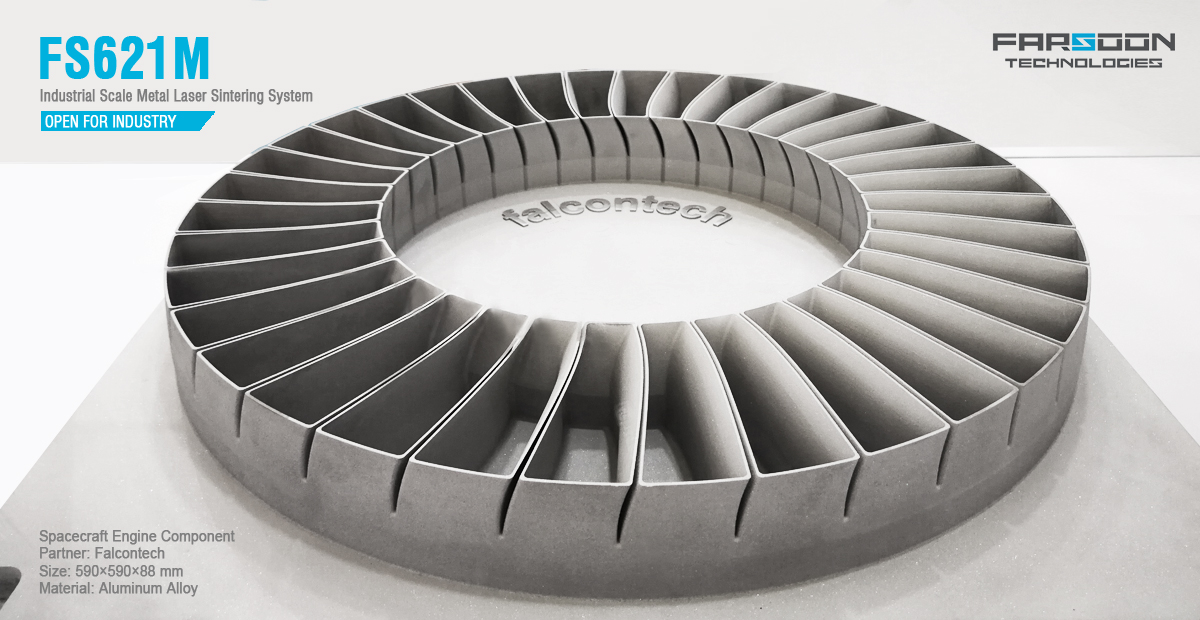

Developed with industry partner and manufacturing service provider Falcontech, the new system has been designed to address the productivity challenges of metal 3D printing including size constraints, powder management and process control. As a result, the FS621M features a large build volume, powerful single or quad lasers and customizable setup, allowing Farsoon customers to enter into the serial production of large format parts.

Farsoon 3D printing and the road to TCT

TCT Asia is the first major 3D printing event to be held since the start of the COVID-19 pandemic, and Farsoon has chosen to launch both its FS621M metal and Flight 252P 3D printers at the conference. In the run-up to TCT, the company has entered into a series of partnerships to develop and apply its proprietary Flight Technology in different applications. For instance, as part of a development agreement with Swiss plastic 3D printing service provider Rapid Manufacturing AG, Farsoon beta-tested its Flight Technology at one of its facilities.

Farsoon later worked with Chinese-based Peak Sport Products Co. (PEAK Sports) to launch its 3D printed shoe ‘solution,’ and Remote Operated Vehicle (ROV) manufacturer QYSEA to produce covers for its FIFiSH V6 underwater ROV. Utilizing Farsoon’s Flight Technology, QYSEA was able to manufacture more than 30,000 protective covers over the course of 2019. More recently, Farsoon announced that it would be collaborating with industry ally Falcontech, to kit out its “Super AM Factory” with 50 Farsoon metal 3D printing systems.

As Farsoon’s new FS621M system has been enhanced for aerospace applications, the new line of 3D printers are already an important part of Falcontech’s Super AM Factory. The large-frame systems have since been utilized to develop and produce spacecraft components for a number of aerospace projects, and Farsoon is now seeking new partners to test its FS621M machines.

Introducing Farsoon’s FS621M metal 3D printer

Farsoon’s newly-announced FS621M 3D printer has been purpose-built to enable the series production of end-use components. Available with either a single 1000W laser or quad 500W lasers, the machine is capable of producing high-quality parts at speed. Farsoon’s focus on large-scale manufacturing extends to the machine’s build volume too, with the 3D printer also featuring a 620×620mm platform and a 1.1-meter vertical axis. According to Farsoon, this makes the system well-suited to potential new applications in the aerospace or oil and gas industries, amongst others.

In addition to being capable of printing at great speed and size, Farsoon’s new metal 3D printer continues the company’s tradition of open-platform printers. Farsoon’s “Open for Industry” philosophy offers customers a high degree of control in tailoring the build parameters of their components, allowing them to produce parts in a cost-effective manner. Moreover, the FS621M’s settings can be specialized for specific applications, including laser parameters, scanning path planning, recoating control, size compensation, and support design. Using the system’s advanced dynamic 3-axis scanning system, powerful build process controls, and real-time recoating monitoring, customers can further optimize the build quality of any parts produced.

The FS621M has also been designed for ease of use, featuring a secondary circulation system with a dual-station filter structure, allowing for filters to be exchanged without disturbing the build process. To make manufacturing even simpler, the printer’s powder handling processes all use the same container during loading, unloading, and sieving procedures, offering fully-sealed powder handling that’s easy to transport and safe to store. Overall, this partially closed powder system allows for the continuous feeding of powder to the build, while retaining the user’s ability to easily exchange and monitor powder quality.

At present, seven of the machines have been installed on behalf of aerospace and large-scale manufacturing customers. Tests have since focused on large-volume fabrication, production with multi-lasers, and processing development of industrial powder materials. Farsoon is now looking to work with additional partners in China on the FS621M Beta system and is encouraging interested parties to reach out.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Farsoon’s FS621M large-format metal 3D printer, which the company debuted at TCT Asia 2020. Image via Farsoon.