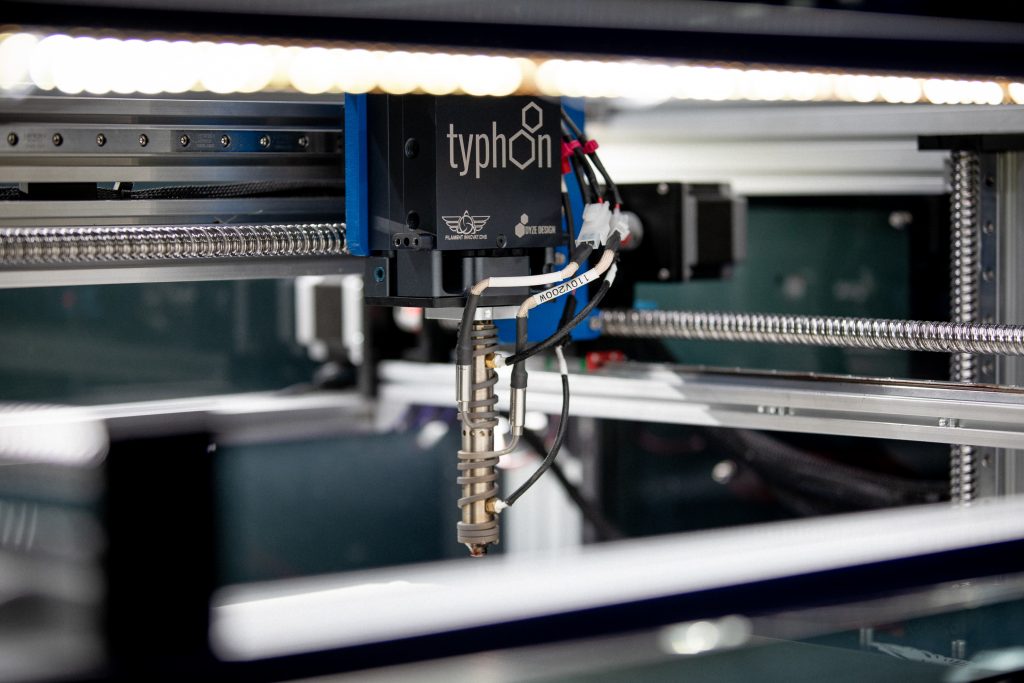

Canada-based OEM Dyze Design is officially releasing its new print head, Typhoon™. Designed for large-scale 3d printers, the Typhoon extruder can output 0.9 kg of material per hour, 10 times the speed of a standard extruder such as DyzEnd/DyzeXtruder. Simply put, a generic 16 hours print would only take from 1 to 3 hours with the Typhoon™ extruder.

“With PLA, we achieved a flow rate of 200mm3/s. However, with materials such as carbon fiber or any filled material, you could even reach 25% to 50% more speed compared to PLA. By using the Typhoon on a part production line, for instance, you could literally multiply your production rate. Each printer is able to make more parts, so at the end of the day, it means more money in your pocket” said Philippe Carrier, Chief Technology Officer, and co-founder of Dyze Design.

The Typhoon is described as a high flow industrial extruder enabling printing of any materials, from common polymers to more advanced engineering filaments, thanks to its maximum operating temperature of 500 °C and its integrated liquid-cooling loop.

“Typhoon is really your go-to solution for any 2.85 mm filament. Obviously, PLA and ABS work like a charm, but the extruder was designed with professional or industrial printing in mind. PETG, Nylon, PEEK, PEI, PVA, HIPS; all that can be printed really, really fast with Typhoon,” adds Philippe.

Not to mention that Dyze focused on improving the overall performance with flexible materials like TPU or TPE, a lot harder to print at a higher speed. Typhoon features a NEMA23 motor and a 4.6:1 gear ratio. The heat core benefits from a dual heating zone to make sure that the temperature remains constant. Finally, the feeding mechanism is an innovative quad pinch geared system, allowing four points of contact with the filament to reduce slipping. All those characteristics ensure a maximal flow rate with each and every filament.

Moreover, usability was at the forefront of Typhoon development. That’s why Dyze Design added some interesting functionalities such as an easy filament swap or quick nozzle change.

“Using the top lever moves all driving mechanisms away from the filament, allowing filament switching in just a second. Each heat core, or nozzle if you will, can also be switched easily with a few knob turns. The advantage is that you could dedicate one heat core per material type, speeding up the cleaning and purging process,” says Dyze’s CTO.

This rugged extruder is also compatible with any standard open-source firmware, for example, Marlin, RepRap, or Repetier.

Last year, Dyze Design managed to do rigorous testing of the extruder through a beta-testing program. Several 3d printer manufacturers tested and provided feedback, such as Modix 3D, Trideo, Filament Innovations to name a few. Besides, they all announced the integration of Typhoon in their current ecosystem or new printer line.

The Typhoon™ extruder is now officially open for preorders. Visit the Typhoon Extruder page to order a unit. Preorders will be fulfilled in August.

Featured image shows the Typhoon™ Fast Print Extruder. Photo via Dyze Design.