Dr. Joshua Pearce’s lab at Michigan Technological University is always at work making strides in 3D printing, ecological sustainability, and reducing poverty. Pearce’s latest contribution to the battle for improving the human condition is not so much on the technological front, like his lab’s low-cost metal 3D printer, but on the societal front. The professor, along with Michigan State’s Savanna Feeley and Michigan Tech PhD candidate Bas Wijnen, has co-authored a paper laying out standards for producing ethical, fair trade filament.

In writing “Evaluation of Potential Fair Trade Standards for an Ethical 3D Printing Filament”, published in the Journal of Sustainable Development, Pearce et al. examine the present dominant model for producing and using filament before developing a set of standards for classifying fair trade filament. The authors write:

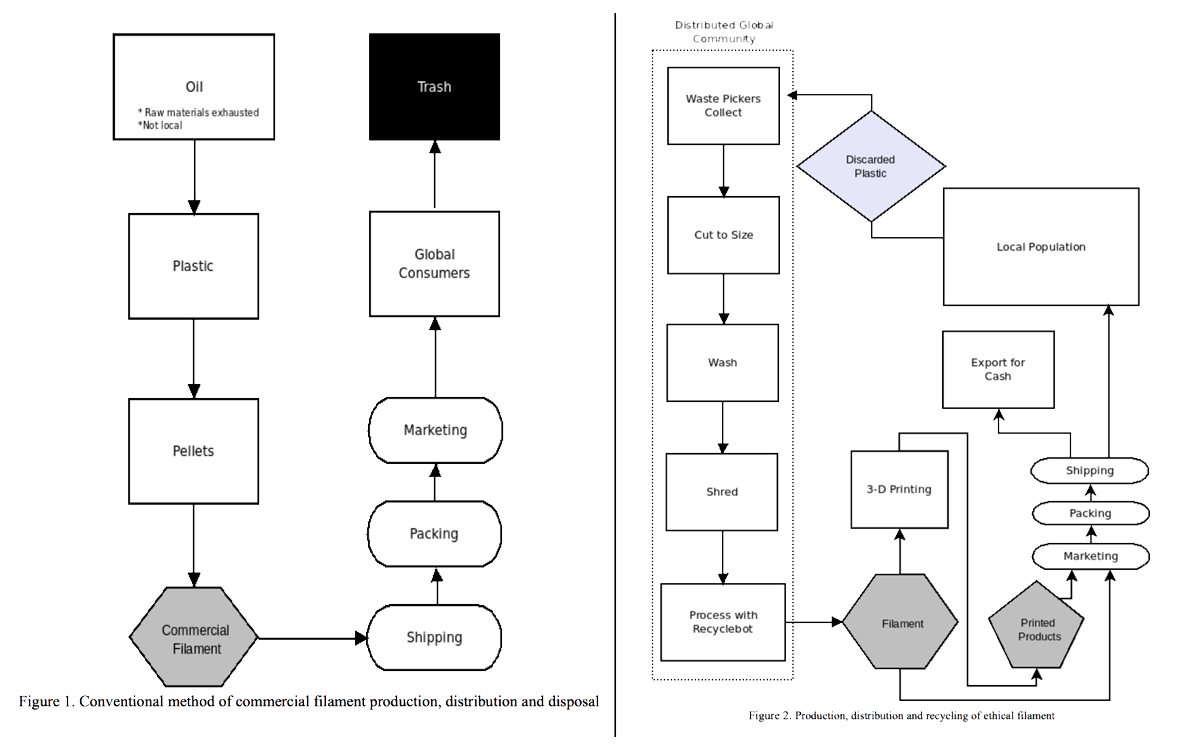

Currently 3-D printer filament is generally mass manufactured and distributed like any other product using raw virgin materials, which are eventually discarded as seen in Figure 1. As can be seen in Figure 1, the plastic is processed from oil (although it should be noted some time natural gas or bio-based feedstocks are used), turned into pellets and then pushed through commercial scaled extruders. When the filament is completed it is packaged and shipped after being marketed to a consumers all over the globe. After printing this filament is presumably trashed following the standard model of consumer good and most likely ends the material life after being transported to a landfill.

The paper then outlines how we might source 3D printing filament that benefits waste pickers in the developing world, while simultaneously reducing waste on the planet and supplying a growing market. Pearce tells Michigan Tech News, “We are creating a new class of material called ethical 3D printing filament, like fair trade coffee. It’s a way to help the poorest of the poor up the economic ladder.”

Just as groups like Fair Trade International and Fair Trade USA use criteria for labeling consumer products as “fair trade”, Pearce and his co-authors have written up a proposed list of standards for ensuring that filament fulfills similar requirements. Then, filament suppliers can sell fair trade filament to ethically-minded consumers. The standards they’ve developed, as listed in the paper, are listed below:

- i) minimum pricing

- ii) the potential for and the application of a fair trade premium

- iii) labor standards

- iv) environmental standards

- v) health and safety standards

- vi) social standards including those that cover discrimination, harassment, freedom of association, collective bargaining and discipline.

While some of these standards are already in place in other industries, 3D printing filament requires its own sustainable practices for producing material. Pearce’s lab has already designed their RecycleBot for converting milk jugs and plastic refuse into filament, which individuals might hypothetically use to produce their own filament for sale to local 3D printer users. Protoprint is an Indian-based company, previously covered on 3DPI, that has already organized waste pickers to process plastic trash into 3D printer filament. Pearce argues that even these companies can earn a profit, while undercutting the majority of the market, “Filament prices are so high that places like Protoprint could sell their filament at half that price and still give pickers a living wage while doing good for the environment.”

The UK’s techfortrade, which has partnered with Protoprint in its efforts, has already established the Ethical Filament Foundation, seeking to address some of the exact concerns Pearce and his colleagues posit in their paper and is planning to implement the standards they’ve developed. The nonprofit’s CEO, William Hoyle, says. “Joshua’s knowledge and his passion, plus his open, collaborative approach, persuaded us that his ethical filament standards would do for 3D printer filament what Fair Trade did for coffee. We’re now close to making this idea a reality; Protoprint is planning to make the first ethical filament offering available in January, and our other ventures in Latin America will follow.”

On the one hand, it bums me out that a set of standards for ethical filament production even has to be written up in the first place and that we, as a society, don’t implement ethical working conditions and manufacturing guidelines as the norm. On the other, the fact that humanity is always making progress, ever so slowly, towards a more just, ecologically balanced means of living, really makes me happy. As always, I’m super psyched by the work that Pearce’s lab has done to make life better for everyone! To read more about what he and his researchers are up to, check out our interview with Dr. Pearce here and visit his lab’s website here. You can read the full paper on their fair trade filament standards here (PDF).

Feature image via Do It Wiser.