Dr. Jean-Christophe Leroux, Professor in Drug Formulation and Delivery at ETH Zürich, has led the first in-human study of 3D printed drug-eluting mouthguards.

Conducted in collaboration with researchers at the Institute of Bioengineering and Nanotechnology in Singapore and the University of Montreal in Canada, the work, as stated in the opening abstract, “demonstrates the immense potential of 3D printing as a platform for the development and translation of next-generation drug delivery devices for personalized therapy.”

The rise of personalized medicine

Though in many ways an age-old practice, new diagnostic approaches have given rise to a contemporary understanding of personalized medicine. In the practice of this procedure, medical therapies are given to patients based on an understanding of their genetic content or cellular analysis, rather than the traditional “one size fits all” approach.

For many researchers and companies operating in this field, 3D printing is playing an instrumental part in the practice of personalized medicine, as it facilitates the fabrication of patient-specific medical devices and drugs.

The ETH Zürich study is proof of one such concept.

From process to patient in just 2 hours

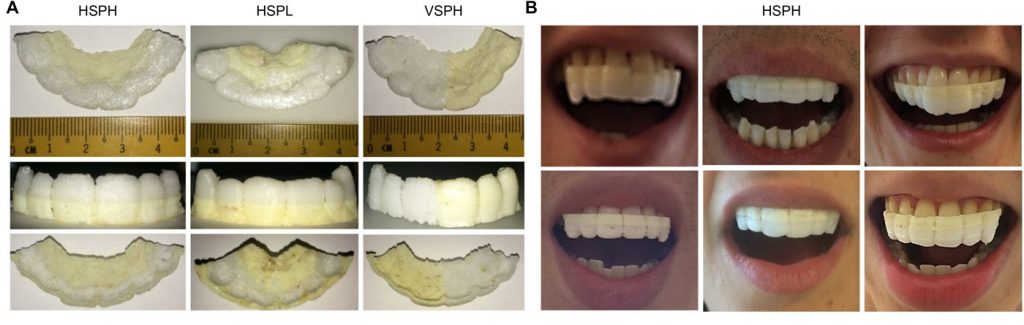

Leroux et al’s study is based on data collected from six volunteers, each wearing drug-eluting mouthguards for two hours a day, three days per week. With one week inbetween tests, a total of three design variations were tried in the period of this experiment.

Now for the fabrication of each guard, already a common 3D printing application, the study leverages the strength of well established 3D techniques.

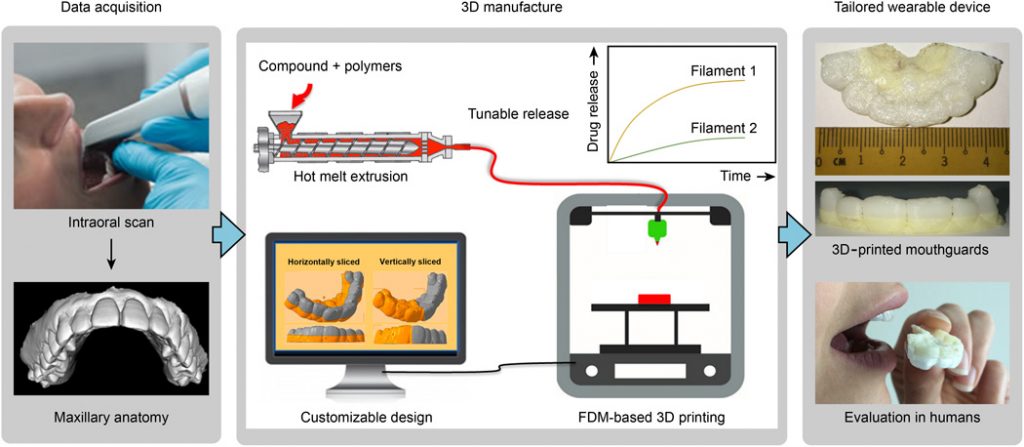

In the first stage, 3D scanning is used to make a digital impression of volunteer teeth, as practiced in dentistry.

Once modeled as a mouthguard, the teeth are then fabricated using commercially available FDM 3D printers. Following suit, 3D printable PVA or PLA is used as the feed material, both of which already are appropiately certified for use in medicine.

The whole production process “from the intraoral scan to the final wearing of the customized VA-loaded mouthguard” took less than 2 hours for each volunteer – a promising result for the process’ replication for on-demand manufacturing.

The next step

The PVA and PLA used in this study were specially formulated in the lab to include an anti-inflammatory drug as the active ingredient. Printed as a mouthguard, the drug is gradually released, which brings certain benefits.

The main advantage of this approach is that slow-release reduces the risk of the drugs being washed away by saliva, or overswallowing a high-dosage and creating unwanted side effects. Validating this approach were the results showing every trial volunteer successfully received the recommended dosage.

Additionally, the team discovered that the main factor influencing drug release was material composition rather than variables such as shape, form and infill. Based on this information, the researchers predict the technique could easily be translated to the production of other medical devices such as stents and implants.

The next step is to look into other potential materials, to open up the selection of drugs that can be loaded and 3D printed as medical devices.

“3D printing of a wearable personalized oral delivery device: A first-in-human study” is published online in Science Advances. It is co-authored by Kun Liang, Simone Carmone, Davide Brambilla and Jean-Christophe Leroux.

For more cutting-edge 3D printing powered research, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook for all the latest stories.

Sign up to 3D Printing Jobs and seek new opportunities in your field.

Featured image shows design optimization in ETH Zürich’s mouthguards. Image via Science Advances, supplementary materials.