Essentium, the manufacturer behind the High Speed Extrusion (HSE) 3D printer series, has launched its new Essentium PEKK 3D printing filament.

The high-performance polymer is known for its mechanical strength, high heat resistance, and excellent chemical resistance, making it a prime choice for high stress aerospace parts and other industrial applications.

Made using Arkema 6002 Kepstan resin, the new PEKK offering is being demonstrated on Essentium’s HSE 280i HT IDEX 3D printer at the Rapid + TCT event this month.

Brandon Sweeney, co-founder of Essentium, said, “Industries such as aerospace and automotive want AM to give them speed to parts without sacrificing quality. By providing an open additive ecosystem with a range of high-performance materials such as PEKK combined with the powerful capabilities of the HSE 280i, industry players now have a unique opportunity to rapidly produce complex parts for harsh and extreme environments on-demand.”

PEKK for HSE 3D printing

PEKK, much like PEEK, is a semi-crystalline thermoplastic from the polyaryletherketone (PAEK) family of polymers. The material shares many of PEEK’s high-performance properties but features a lower crystallization rate, meaning it can be treated as an amorphous polymer. As such, it’s less affected by the rapid cooling process 3D printed parts experience after fabrication, reducing warping and dimensional imprecision.

With an extrusion temperature between 340°C and 400°C, PEKK also offers flame-retardancy properties. This is crucial for meeting the flame smoke toxicity ratings for FAA (Federal Aviation Administration) compliance, making the polymer suitable for flight-ready components. Additionally, it offers improved chemical resistance when compared to PEI.

The Essentium HSE 280i HT

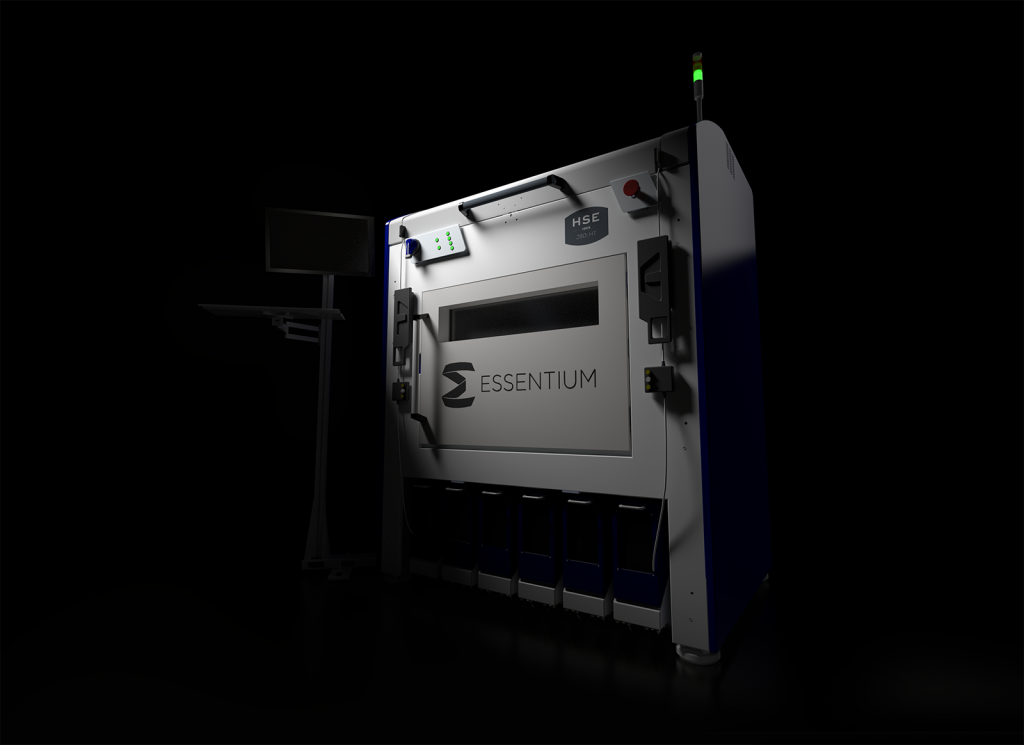

The Rapid + TCT display will also be the first time Essentium showcases its HSE 280i HT system in the US. Launched back in April 2021, the high-temperature IDEX 3D printer is defined by its large 695 x 495 x 600mm build volume, high-throughput production capabilities, and engineering material compatibility.

Aimed at high-volume manufacturers in a variety of sectors such as aerospace, electronics, automotive, and consumer goods, the HSE 280i HT features a maximum nozzle temperature of 550ºC has been optimized for both functional prototyping and end-use production. Essentium has equipped its system with a non-slip, high torque extrusion system and linear servo motors, enabling print speeds of up to 500mm/s and 5x – 15x the throughput of similar competitors.

The printer is described as a ‘true IDEX’ system. While most IDEX printers have printheads that are independent in the X-axis but locked together in the Y-axis, the 280i HT is fully independent in both. The design consideration gives users five different build modes to play around with: single head mode, support mode, multi-process mode, copy mode, and independent mode.

Sweeney adds, “These AM innovations are game-changing for manufacturers who are driven by improvements in efficiency and time-to-market opportunities.”

High-performance filaments like PEKK are imperative if FDM 3D printing is to be used for industrial applications. Earlier this summer, German chemicals company Evonik announced the launch of its new PEEK-based 3D printing biomaterial. Designed specifically for medical applications, VESTAKEEP Care M40 3DF filament is safe for body contact for up to 30 days and can be 3D printed on any common high-temperature system that usually processes PEEK.

Elsewhere, Fillamentum, a leading provider of specialist 3D printing materials, recently launchd its latest high-performance engineering filament. Named Fluorodur, the polyvinylidene fluoride (PVDF) material is characterized by its impressive blend of mechanical, chemical, and thermal properties.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an industrial part 3D printed in PEKK. Photo via Essentium.