Fillamentum, a leading provider of specialist 3D printing materials, has announced the launch of its latest high-performance engineering filament.

Named Fluorodur, the polyvinylidene fluoride (PVDF) material is characterized by its impressive combination of mechanical, chemical, and thermal properties. Made using Kynar PVDF from chemical company Arkema, Fluorodur has already seen use in research projects at the Czech Academy of Sciences.

Tomas Fertek, a research engineer at the Academy’s Institute of Geology, said, “With properties such as high temperature resistance, chemical resistance and hardness, Fluorodur replaced PEEK filament in our institution.”

High-performance 3D printing with Fluorodur

Fluoroplastics like Fluorodur tend to feature high rigidity in their polymer chains, resulting in a highly crystalline structure. The chains are also packed very closely together with small intermolecular distances, increasing the strength of the intermolecular bonds. The result is a filament that exhibits rigidity, toughness, and very high impact strength. Looking at some of the key mechanical properties, Fluorodur offers a tensile strength of 34MPa, a flexural strength of 50MPa, and an elongation at break of 8%.

Owing to a strong set of hydrogen-fluorine bonds, the material also offers excellent resistance to both chemicals and moisture. The non-exhaustive list of compatible substances includes car fluids, halogenated hydrocarbons, alcohols, acids, bases, and ozone. Equally as important is the fact that Fluorodur maintains these chemical resistances at a wide range of extreme temperatures (-40°C to 110°C).

When it comes to thermal properties, the polymer boasts an impressive heat resistance of up to 150°C. Seeing as the polymer chains are halogen-based, the material is also flame-retardant. In the case of a live fire, Fluorodur will burn but quickly self-extinguishes once the heat source is removed, preventing the spread of any remaining flames.

Finally, the filament is also resistant to UV light, making it suitable for long-term outdoor use. In fact, Fillamentum claims its new material remains stable for more than seven years in outdoor environments, maintaining its structure and functionality without any obvious damage. As a bonus, Fluorodur is an electrical insulator, qualifying it for use in electrical and electronic equipment.

A new tool at the Czech Academy of Sciences

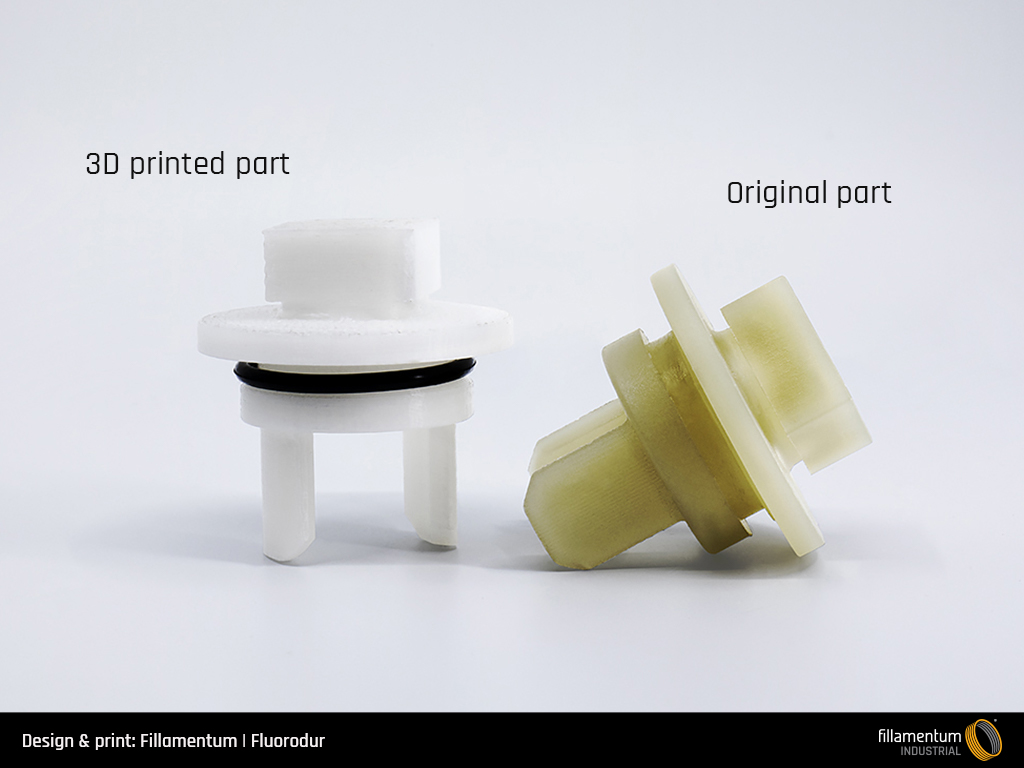

The jack-of-all-trades engineering polymer has already made waves at the Czech Academy of Sciences, where researchers recently used it to 3D print high-strength sealant structures for geology equipment.

The Fluorodur structures were used to vacuum-seal rubber sleeves containing samples of rock. Seeing as the sleeves were to be placed in high-temperature pressure chambers to measure the deformations in the samples, the sealants were required to withstand temperatures of up to 150°C while maintaining integrity. The team also needed a chemically-resistant polymer, as the chamber was to be filled with a hydraulic oil to simulate a triaxial chamber. Meeting all of the project’s needs, Fluorodur made for a perfect choice.

“Fluorodur is for those who don’t want to invest in a new industrial 3D printer or industrial machine upgrades, but are still looking for a mid-range material that is easy to print,” concludes Fertek. “3D printing with the material has helped us produce our own cost-effective sealant structures. We would have otherwise had to order in the parts we needed externally, which is expensive when dealing with such small quantities.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a 3D printed Fluorodur part next to a PEEK part. Photo via Fillamentum.