There is little doubt about it: the only thing that seems to have remained unchanged in this move to Dusseldorf in September from Frankfurt in November is the grey, rainy weather. The new Euromold is definitely a lot smaller, with many fewer exhibitors and visitors than the previous versions that took place for the past two decades. The good news is that 3D printing at Euromold seems to be doing just fine and that the departure of many large companies – EOS, Stratasy, and, Concept Laser among others – has left a lot of room for the new guys to strut their stuff.

This is not just a matter of Euromold Vs TCT/Mesago, or Frankfurt Messe Vs Dusseldorf Messe. The market itself is changing in so many ways and no one is really sure where it is heading. The only thing that I know for sure is that this is the greatest time to be a researcher, an engineer, or a technology journalist.

Even during a clearly low-key event (instead of three huge pavilions, there were only two being used and one was partially closed off), there were tons of exciting news from the 3D printing industry and even more amazing products that I had the opportunity to see up close and personal. And the best part is that – because of the relatively low affluence – the exhibitors could take the time to show them to me in details and explain to me exactly how they worked. Too bad I had to wait until now (almost midnight my time) to write about them, since the Euromold organizers (just like they used to do in Frankfurt) do not offer free Wi-Fi on the show’s premises. So, which were these amazing products? I will try to explore them in the order that I saw them.

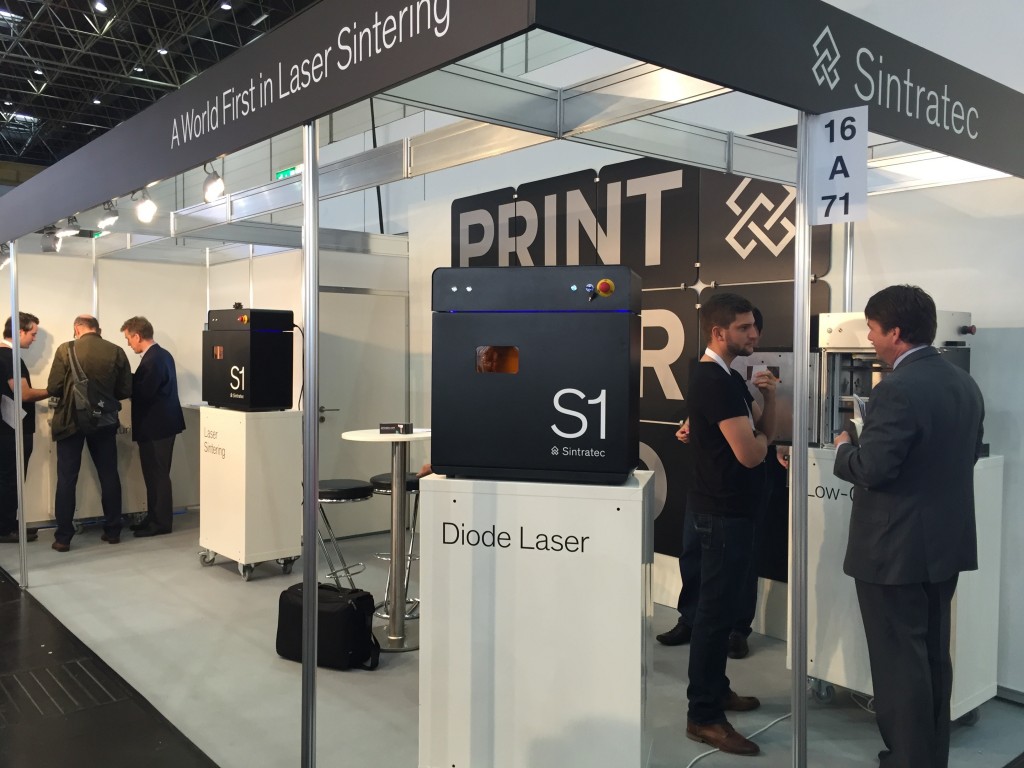

The first product I saw was Sintratec’s new S1 low-cost SLS 3D printer, which is hitting the market at the incredible pricepoint of €9,000. Dominick Soleniki, one of the company’s young co-founders, told me a little about their incredible story and how they began studying the machine’s development as early as 2009, coming up, now, with a system to carefully regulate the temperature in a way that can rival much more expensive systems. I saw the 3D printed pieces, which were truly impressive in terms of quality and resolution, but I did not get to see the machine actually operating.

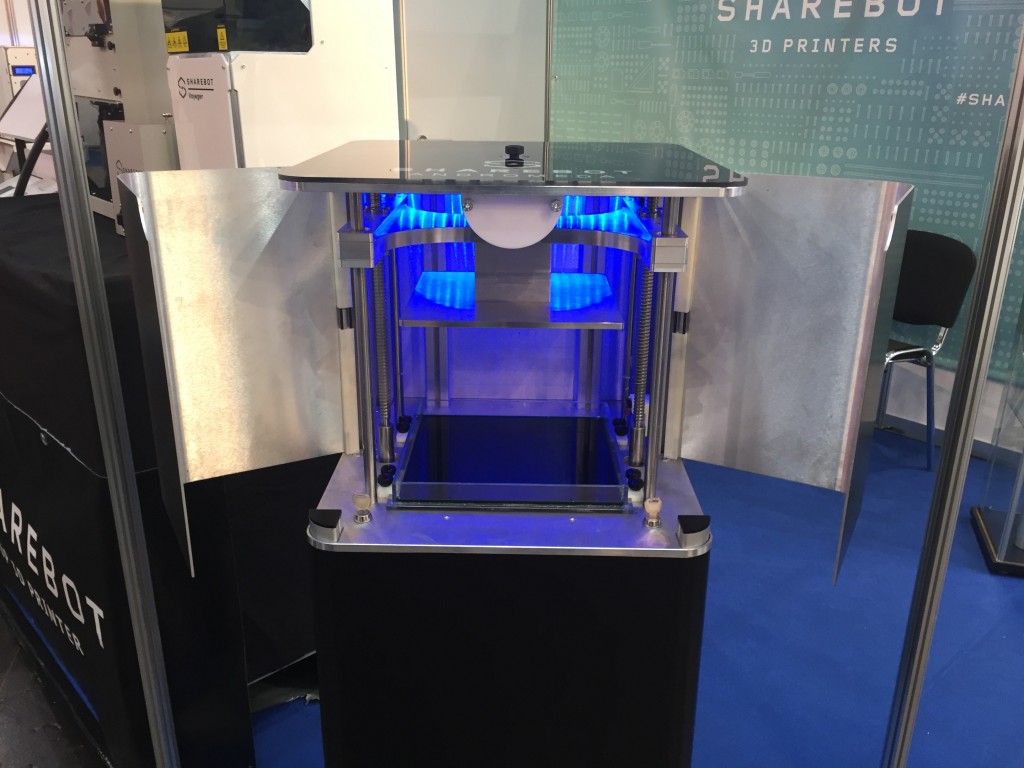

I quickly passed by the HP stand, which, however, has no machine to show yet (other than some new colored, 3D printed parts) and went on to Sharebot, where I got a chance to see the newly released 25 x 25 x 25 cm SLA Andromeda 3D printer (which was even bigger than I had imagined), as well as the fully-functional SnowWhite SLS machine and their entire line up. I also go to see my friend Amin Torabi, who now leads Sharebot Germany.

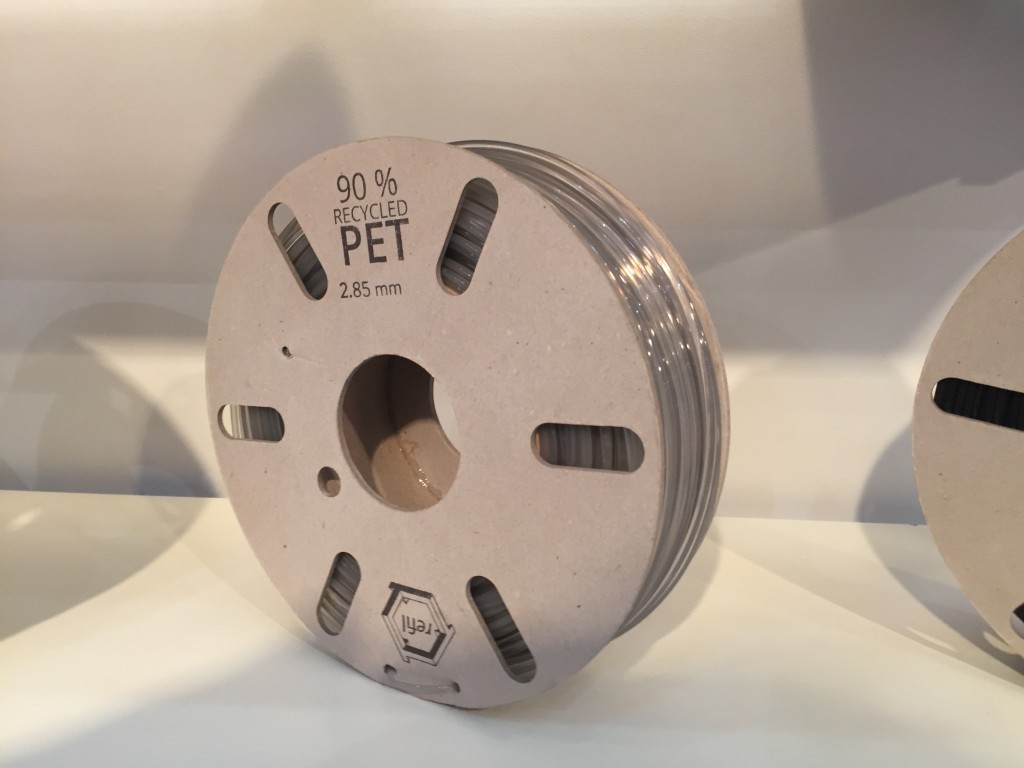

Before moving on I stopped by the nearby Better Future Factory (the design studio that created the Perpetual Plastic Project concept). I finally met the CEO, RJ Martens, whom I just missed during my trip to the Netherlands last year, and he showed me their new recycled PET and ABS filaments, with cardboard spools (more on this in a separate article). I then moved on to a closed door meeting with Formlabs’s Sara Bonomi, before meeting with Vanessa Palsenberg at Materialise’s conference.

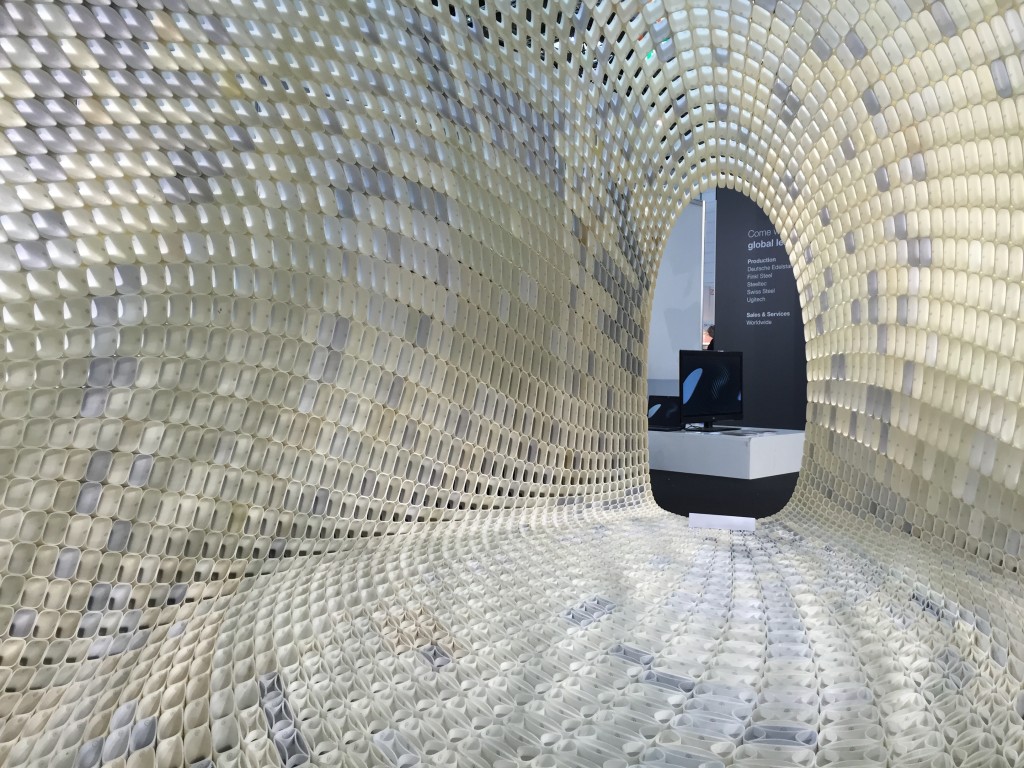

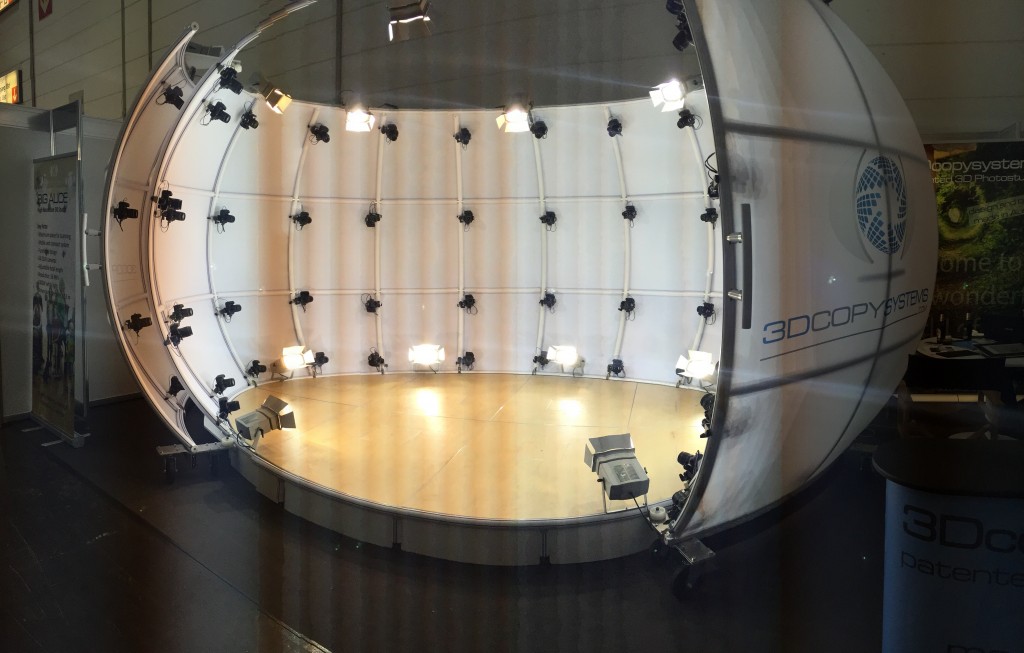

On the way back down to the show floor, I also passed by two very catchy egg-like structures: one is the now famous collectively 3D printed Egg Project (which I did not have time to go see when it came to Milan for the last Design Week), and the other is a new photogrammetric 3D scanning booth (there were lots of those on the show floor) by a new Austrian company called 3DCopySystems.

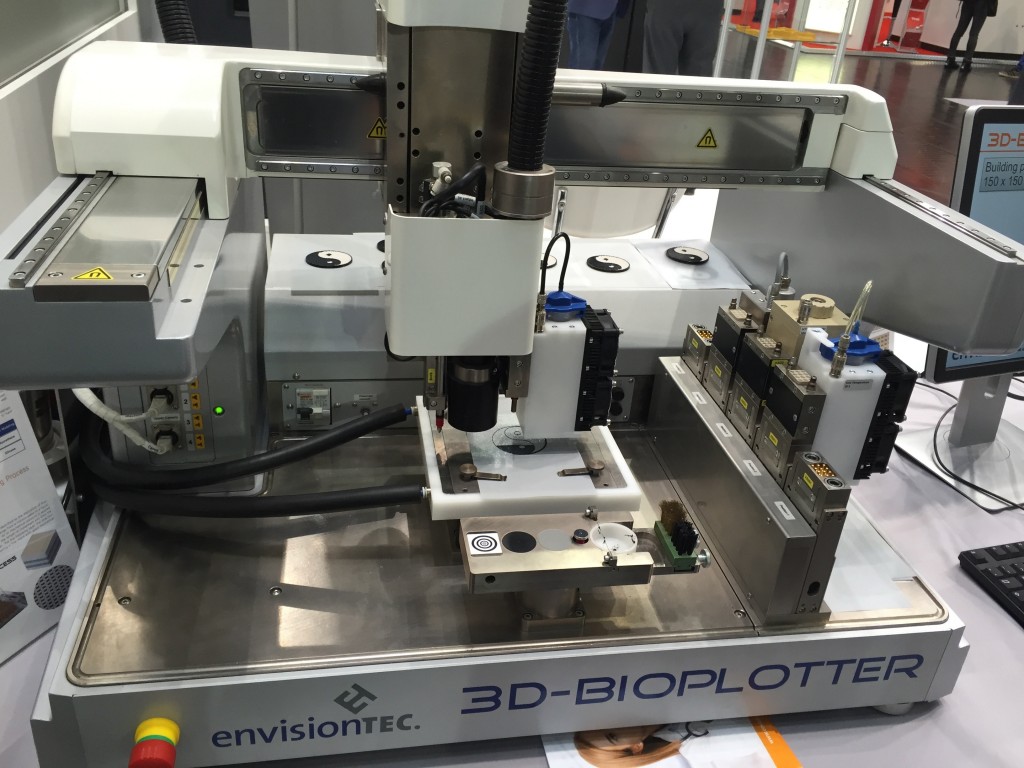

Speaking of bioplotters, I also got to visit EnvisionTEC’s huge stand, where I could see tons of incredibly high accuracy 3D prints of entertainment properties all kinds, even including a Star Wars drone model (could it be a hint of something concerning Star Wars VII?). Here I also got to see the huge, 4th Generation 3D bioplotter, hard at work extruding silicon paste.

One last company I really wanted to see on the show floor was 3D Ceram and I was not disappointed. Almost at closing time, I spoke with Marc-Emmanuel Favre, in charge of business development, and he spent a good deal of time showing me the amazing potential of the ceramics 3D printing technology. I am not sure if the image below can accurately convey the beauty of the 3D printed ceramic parts that come out of their machine, but there is little doubt in my mind that this is going to play a big part in the future of both prototyping and medical 3D printing.

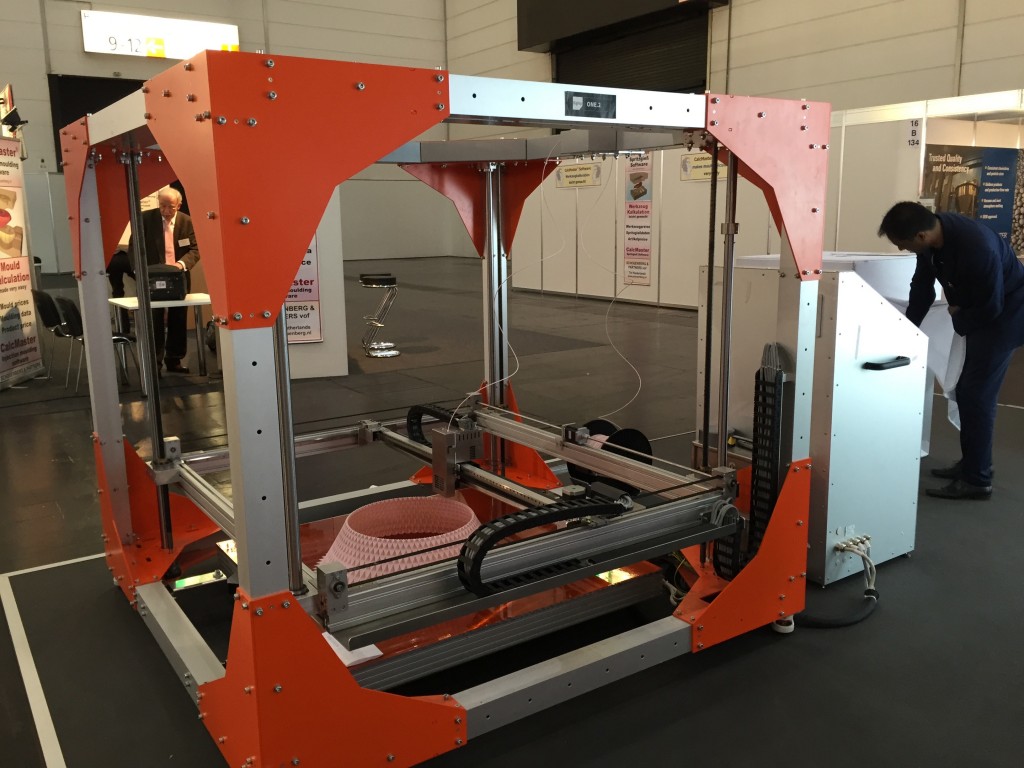

As I was heading out, I ran into two of the biggest 3D printing technologies around: BigRep, with its BigRepOne.2, and Sciaky, with its amazing EBAM 3D welding technology. Both companies are still relatively small today, but they can 3D print huge objects. In this new, low key, Euromold, they already stand out like giants.