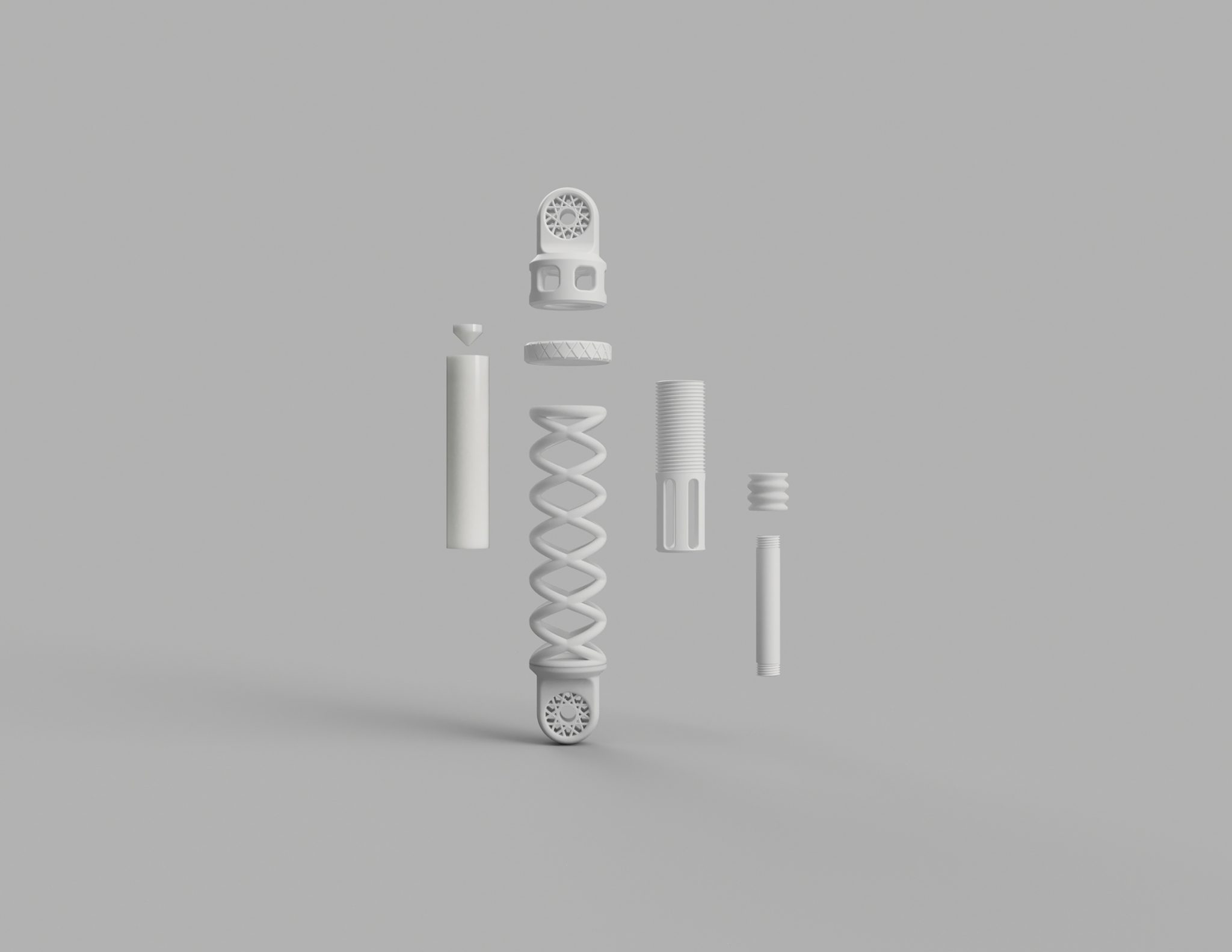

Covestro, a German manufacturer of high-performance polymers, has created a complex 3D printed shock absorber demonstrator using three different materials and additive manufacturing processes. This novel component will be showcased at the Fakuma 2018 trade fair next month in Friedrichshafen.

“This complex structure would not have been possible with conventional production processes,” said Lukas Breuers, Marketing Manager for 2D & 3D Printing at Covestro.

“The combination of different materials with various, tailor-made properties has enabled us to significantly expand the possibilities of additive production and its areas of application.”

Creating a shock absorber using SLS, FDM, and DLP

Covestro’s extensive range of resins, filaments, and powders, has served the automotive, construction, cosmetic, health and chemical industries since its inception in 2015. With the aim to bring “mass manufacturing to the 3D printing world with a range of high-quality products,” the company has developed a complex 3D printed shock absorber for the automotive industry.

Shock absorbers are critical hydraulic devices inside a vehicle’s mechanism which reduce unwanted kinetic energy. Using Selective Laser Sintering (SLS) and TPU powder, for its elasticity and high abrasion resistance, engineers fabricated the outer spring of the part which measures at 40 x 7 cm (15.7 x 2.8 in).

However, the adjusting screw inside the shock absorber required a high strength component for support. Thus, it is made from Covestro’s robust polycarbonate filament with FDM technology. Furthermore, the air chamber within the interior is created from a liquid PUR resin using the Digital Light Processing (DLP) method. This process was chosen due to its use within components with filigree structures – ornamental work using gold or silver wires interwoven to make fine lace patterns.

The functional 3D printed shock absorber will be displayed from October 16-20th at Fakuma 2018.

NASA’s 3D printed pogo accumulator

Additive manufacturing has been present within other advanced industries such as aerospace, due to its ability to produce complex metal components demonstrating lightweight yet superior mechanical properties.

Last year, NASA’s Space Launch System (SLS) project, and Aerojet Rocketdyne, began reducing the weight of components in the fabrication of 16 shuttle engines, within rockets to help propel manned missions to Mars. Using selective laser melting (SLM), the partners created an RS-25 3D printed pogo accumulator, similar to a shock absorber, to dampen vibrations caused by the rockets propellants.

The components of the accumulator reduced the number of welds in a conventional part by 78%. This part was also hot-fired tested inside an RS-25 space engine for over 400 seconds.

Keep up with exclusive interviews and the latest 3D printing news by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Searching for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows an exploded view of the 3d printed shock absorber. Photo via Covestro.