A $6 million state-of-the-art 3D printing facility is planned for the the city Visakhapatnam in India. Also known as Vizag, the city is the financial capital of the Indian state of Andhra Pradesh.

The additive manufacturing center will be built under an agreement between Andhra Pradesh MedTech Zone (AMTZ) and think3D. Raja Sekhar Upputuri is the co-founder of think3D who operate in 11 cities across the country. With over 1,000 customers think3D is India’s largest 3D printing platform.

AMTZ (AP Medical Tech Zone) is an SPV formed by the Indian government and the provincial government of Andhra Pradesh to promote medical device manufacturing in India and reduce dependence on imports for medical devices.

Addressing a $5.5 billion market

3D Printing Industry asked Raja Sekhar Upputuri a few questions about the plans.

“Currently the land development works are going on,” says the think3D co-founder. “Our facility and a few manufacturing companies should be open by October 2018. For full fledged activity in the park, it would easily take another 3-4 years.”

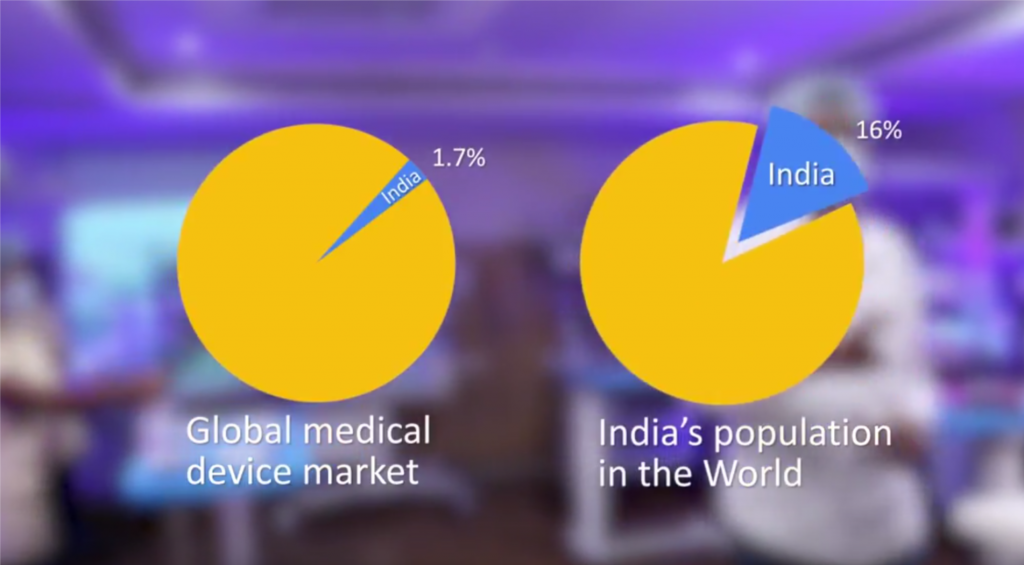

Vizag has the tenth largest economy in India. The planned 3D printing facility is intended to address the $5.5 billion Indian medical market, a figure that is expected to grow substantially in coming years. Currently approximately 75% of demand is met by imports. This means that the price of medical devices can fluctuate with currency movements, furthermore by importing the devices an opportunity to create jobs in the country is missed.

As previously reported by 3D Printing Industry, several countries are also establishing specialist medical 3D printing centers.

3D printing supports best-in-class manufacturing infrastructure

The $6 million facility is part of the central government’s “MAKE IN INDIA” project, a major national initiative designed to foster innovation and build a best-in-class manufacturing infrastructure.

The project provides an insight into the potential of 3D printing for Newly Industrialized Countries to leapfrog a development stage and move directly to advanced manufacturing. According to think3D,

Medical device manufacturing requires huge up-front investment in R&D, machinery and QC facilities. Some of these facilities have very little utilization rate but are required as part of the manufacturing process. Taking this into consideration, the government has decided to set-up these common facilities in partnership with private entities and offer these facilities to manufacturers within park on pay per use basis thus reducing the upfront investment from manufacturer cost drastically. 3D Printing & 3D design facility is chosen as one such common facility.

Come with an idea, leave with the finished prototype

Raja Sekhar Upputuri tells us that the facility will employ between 50 to 60 people. Work is underway to determine the 3D printing technology requirements, as he says,

We haven’t yet zeroed in on brands. As for types of machines, we definitely will have 1 metal 3D Printer, 2 – 3 SLS 3D Printers, a few SLA / DLP machines, many FDM machines, a few high end scanners like Artec, Faro. We also will have 1 or 2 CNC Machines, Vacuum casting machines as for some prototypes we need to employ traditional methods.

In additional to 3D printing, the 20,000 sq ft space will include state of-art reverse engineering facility and an expert 3D design facility. The intent is that, “manufacturers can come to the facility with just an idea and leave with the finished prototype.”

Raja Sekhar Upputuri also told us more about how 3D printing will be used in production of medical devices.

3D Printing will be used for prototype and batch production of few parts for medical devices. For example MRI, ECG, Ultrasound machines, different types of syringes and so on. TUV Rhineland is setting up a testing center in the facility to thoroughly test these devices before they are launched in the market.

The aforementioned TUV Rhineland deal is a partnership with Andhra Pradesh MedTech Zone (AMTZ). Under a public private partnership (PPP) – estimated at $13 million – the testing facilities will also be established in the region.

Dr. Jithendra Sharma, CEO AMTZ, explains, “We realized the need to have mega industrial partners in AMTZ. They will support manufacturers in producing quality product at an industrial cost-effective scale.”

The Andhra Pradesh MedTech Zone is India’s first manufacturing park specialising in medical technology, the zone will occupy 270 acres.

For all the latest 3D printing news and insights, direct from those involved, sign up to our free newsletter and follow the most widely read social media accounts.