It is arguable that the expected uptake of VR has been slower than expected. This may in part be due to cost of the necessary computing power.

Inspired by a request from an orthopedic children’s hospital in Nepal, HRDC, a Lake Placid, NY enterprise has created an innovative solution combining 3D printing with affordable VR medical modelling to save time and improve patient experience.

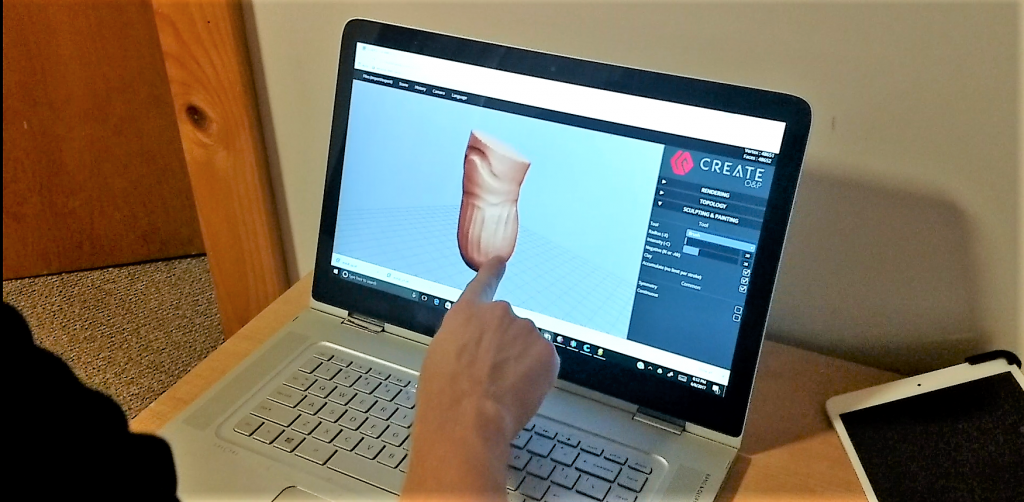

Create Orthotics and Prosthetics has developed a software tool that can be used with inexpensive VR, such as the Google Daydream, “to let any clinician quickly design a prosthesis, 3D print and test fit the custom parts in less than 3 hours.”

3D Printing Industry asked Gary Ziele, Director of Sales and Marketing at Create Orthotics and Prosthetics, for more information.

An intuitive VR workflow to create medical devices

3D printing has found frequent application for making custom prosthetic and orthotic devices. Indeed, Create O&P has already worked with one of the most widely known groups active in this area – the Enable Community Foundation.

However, the latest Create O&P solution is different. Here the focus is on the workflow required to make custom medical devices. The company explains,

A clinician scans a patient and uploads the scan to a smartphone. He/she then puts on a headset and modifies a digital plaster mold in a virtual world by hand, just like he/she normally would with plaster. Then, the clinician designs a test socket around the digital mold and sends it to a 3D printer to fabricate in under three hours. This software utilizes the same tools that clinicians are already comfortable using, except there is no mess, no waste, and a much more efficient workflow. This is all possible using just a smartphone and a VR headset.

Gary Ziele gives more details, “The benefit of 3D printing is to use digital techniques to rapidly produce prosthetic devices.” As practicing prosthetists, the Create O&P team also recognised that while traditional methods of working by hand may be inefficient, practitioners may not initially be willing to try a new method.

Ziele says any new technique must offer benefits beyond the standard practice and must also be intuitive for practitioners. He continues,

Just having the hardware won’t be enough. [Practitioners] will need a workflow that they can comfortably adopt, using familiar techniques and skills. Using our intuitive software in VR, they can use the same tools, hands on techniques and skills they are used to when modifying plaster, but now with the all the digital benefits. This would eliminate all waste and mess. With our new system, they will be able to implement a more efficient workflow requiring far less man-hours to fabricate a device. This new workflow will give them more time to see patients, while being very easy to adapt to.

A custom 3D printer for prosthetics and orthotics, freely available VR software

Certified Prosthetist-Orthotist (CPO) and the founder of Create Jeff Erenstone says, “We see that tools such as VR are a great way to empower practitioners to use their existing skills and techniques in a new digital platform.”

The VR software tool can also used with a 3D printer. “Clinicians can scan a patient, design a digital check socket, print the device, and fit the patient, all within the same day.”

Create has partnered with U.S. 3D printer manufacturer Printrbot to build a 3D printer that meets the needs of the Orthotics and Prosthetics market. Gary Ziele explains,

For instance, our high-flow hot end will greatly decrease print times for various prosthetic devices. As for our software, all the tools and features were developed to mimic what practitioners are currently used to. We are currently registered with the FDA. Our systems are fully compliant with all FDA and medical insurance requirements as well. In regards to training, our on-staff CPOs conduct multiple sessions on how to 3D print and how to apply it to the O&P industry. So our printer is only part of the equation.

“In the developing world, we want to subsidize this software, making it freely available to allow clinicians to access this vital technology,” says Erenstone. “Our goal is to improve prosthetic care, no matter where a person lives in the world.”

Let us know your thoughts about combining 3D printing with VR to create medical devices in the comments below.

For all the latest news about the 3D printing industry, subscribe to our free newsletter. Also, you can follow our active social media accounts.

Featured image shows Create Orthotics and Prosthetics CEO and founder using VR to create custom medical devices. Photo via Orthotics and Prosthetics.